Composite self-insulation wall energy-saving system

A self-insulation and wall technology, which is applied in thermal insulation, building insulation materials, walls, etc., can solve the problems of easy condensation at the thermal bridge, water leakage in the external insulation system of the external wall, hollowing of the self-insulation block wall, etc. Achieve excellent mechanical properties, improve comfort and safety, and solve the effect of empty drums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Lightweight masonry mortar is made of the following raw materials by weight: 50 parts cement, 10 parts fly ash, 15 parts light aggregate, 20.7 parts sand, 0.3 parts cellulose ether, 4 parts redispersible latex powder.

[0023] Gypsum-based light leveling mortar is made of the following raw materials by weight: 50 parts gypsum, 5 parts stone powder, 4.4 parts slaked lime, 30 parts light aggregate, 0.3 parts cellulose ether, 10 parts sand, 0.1 parts starch ether, and coagulation adjustment Agent 0.2 parts.

[0024] The flexible insulation putty layer is made of the following raw materials by weight: 40 parts of cement, 7.3 parts of fly ash, 40 parts of light aggregate, 0.3 part of cellulose ether, 0.1 part of starch ether, 0.3 part of water repellent, redispersible latex 12 servings of powder.

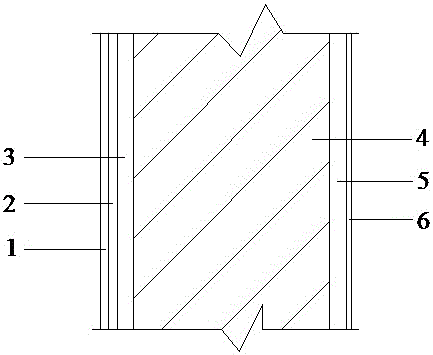

[0025] See figure 1 : The prepared lightweight masonry mortar, gypsum-based lightweight leveling mortar and flexible thermal insulation putty are applied to the composite self-insulatio...

Embodiment 2

[0029] Lightweight masonry mortar is made of the following raw materials by weight: 40 parts of cement, 16.7 parts of fly ash, 25 parts of lightweight aggregate, 15 parts of sand, 0.1 part of cellulose ether, and 3 parts of redispersible latex powder.

[0030] Gypsum-based light leveling mortar is made of the following raw materials by weight: 70 parts gypsum, 3 parts stone powder, 2 parts slaked lime, 4 parts light aggregate, 0.2 parts cellulose ether, 20.42 parts sand, 0.05 parts starch ether, and setting 0.3 parts of air-entraining agent and 0.03 parts of air-entraining agent.

[0031] The flexible insulation putty layer is made of the following raw materials by weight: 35 parts of cement, 2.9 parts of fly ash, 45 parts of light aggregate, 0.5 part of cellulose ether, 1 part of ash calcium powder, 0.2 part of starch ether, 0.4 part of water repellent Parts, 15 parts of redispersible latex powder.

[0032] See figure 1 : The prepared lightweight masonry mortar, gypsum-based lightw...

Embodiment 3

[0036] Lightweight masonry mortar is made of the following raw materials by weight: 45 parts of cement, 25 parts of fly ash, 20 parts of lightweight aggregate, 7.8 parts of sand, 0.2 parts of cellulose ether, and 2 parts of redispersible latex powder.

[0037] Cement-based lightweight leveling mortar is made of the following raw materials by weight: 55 parts of cement, 14.05 parts of fly ash, 25 parts of light aggregate, 0.35 parts of cellulose ether, 2 parts of ash calcium powder, 0.1 part of starch ether, 0.5 part of fiber Parts, 3 parts of redispersible latex powder.

[0038] The flexible thermal insulation putty layer is made of the following raw materials by weight: 50 parts of cement, 6.4 parts of fly ash, 30 parts of light aggregate, 0.3 parts of cellulose ether, 3 parts of ash calcium powder, 0.1 part of starch ether, 0.2 part of water repellent agent Parts, 10 parts of redispersible latex powder.

[0039] See figure 1 :Apply the prepared lightweight masonry mortar, cement-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com