Functional polymer microsphere for automobile coating, and preparation method and production equipment thereof

A technology for production equipment and polymers, applied in the direction of mixing methods, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of insufficient consideration of coating compatibility, inability to be widely used, high cost of processing equipment, etc., and achieve the integration of production equipment High, low manufacturing cost, simplified process and equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

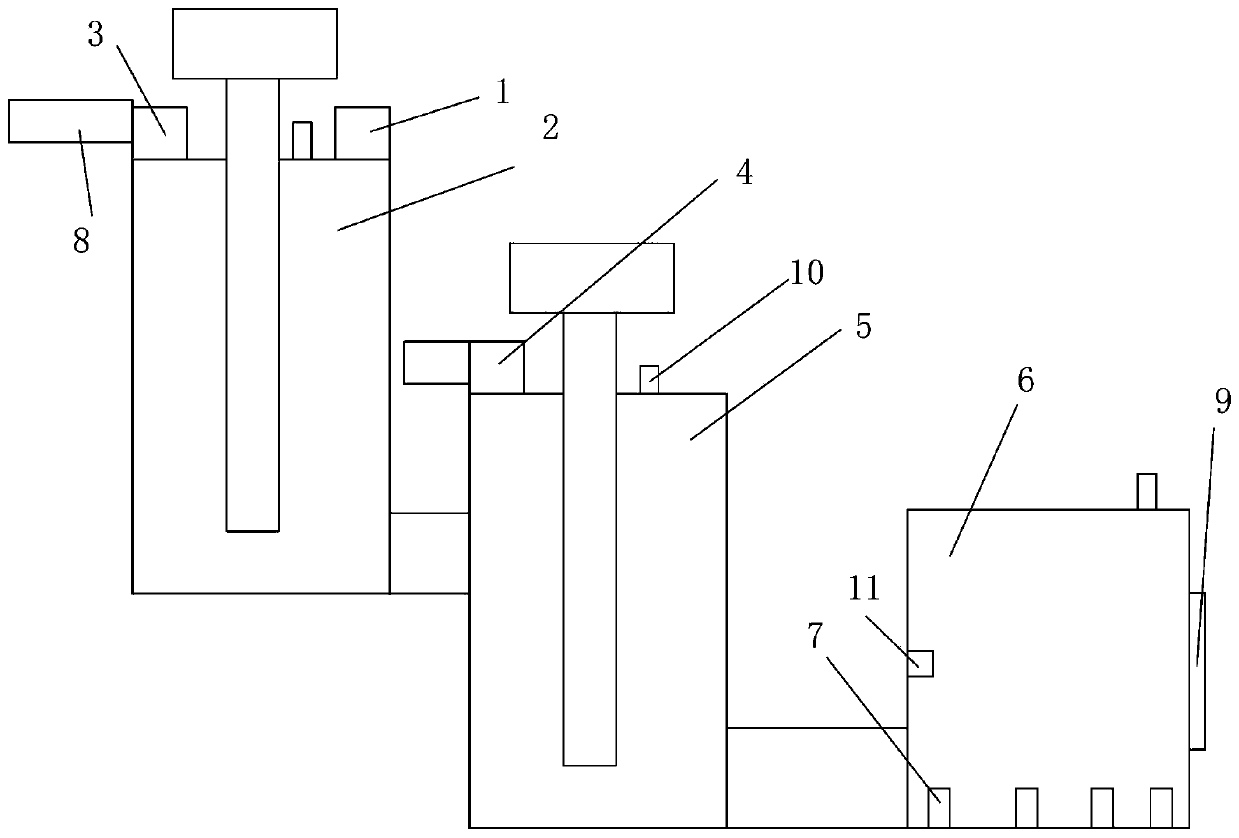

Image

Examples

Embodiment 1

[0033] The functional polymer microspheres for automotive coatings provided in this embodiment are polymer microparticles with a spherical shape and a particle diameter of 500-1500 nanometers prepared from the following components in parts by weight: polymer solution 20.0-50.0 parts; 0.03-0.2 parts of emulsifier; 100-150 parts of water; 0.1-3 parts of initiator; 30-40 parts of functional monomer; 1-3 parts of flame retardant; 1-3 parts of antifreeze agent; 2-3.5 parts of antifreeze agent of alcohol antifreeze agent; 5-8 parts of nano silicon dioxide; wherein: the functional monomer is hydroxyethyl acrylate, acrylic acid, methacrylic acid, acryloylmorpholine , N-vinylpyrrolidone, methoxypolyethylene glycol acrylate, methoxypolyethylene glycol methacrylate, acrylamide, isopropylacrylamide, N,N-dimethylacrylamide, acrylic acid N , A mixture of one or more of N-dimethylaminoethyl ester, glycidyl methacrylate, hydroxypropyl methacrylate, isobutyl acrylate, isodecyl acrylate, and is...

Embodiment 2

[0051] Embodiment 2: the functional polymer microspheres for automotive coatings provided by this embodiment, preparation method and production equipment, it is basically the same as embodiment 1, and its difference is:

[0052] The functional polymer microspheres for automotive coatings are prepared from the following components in parts by weight: 20.0 parts of polymer solution; 0.03 parts of emulsifier; 100 parts of water; 0.1 part of initiator; 30 parts of functional monomer 1 part of flame retardant; 2 parts of anticorrosion agent; 1 part of anti-penetration agent; 3 parts of antifreeze of alcohol antifreeze, 6 parts of nano silicon dioxide; Wherein: described functional monomer is hydroxyethyl acrylate, acrylic acid, A mixture of one or more of methacrylic acid and acryloylmorpholine;

[0053] The polymer solution is a combination of polyethylene lactide, polycaprolactone, and polytrimethylene carbonate, and the ratio of parts by weight is 1:1:1.

[0054]In step ⑤, the ...

Embodiment 3

[0056] The functional polymer microspheres for automotive coatings provided in this embodiment, the preparation method and the production equipment are basically the same as those in Examples 1 and 2, except that:

[0057] The functional polymer microspheres for automotive coatings are prepared from the following components in parts by weight: 50.0 parts of polymer solution; 0.2 parts of emulsifier; 150 parts of water; 3 parts of initiator; 40 parts of functional monomer 3 parts; flame retardant 3 parts; anti-corrosion agent 3 parts; anti-penetration agent 3 parts; alcohol antifreeze antifreeze 3.5 parts; Wherein: the functional monomer is one or more of N-vinylpyrrolidone, methoxypolyethylene glycol acrylate, methoxypolyethylene glycol methacrylate, acrylamide, and isopropylacrylamide mixture of species.

[0058] The polymer solution is a composition of polyethylene lactide, polycaprolactone and polytrimethylene carbonate, and the ratio of parts by weight is: 0.5:0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com