Light-weight strengthened composite insulation board and manufacturing method thereof

A technology for enhancing compounding and manufacturing methods, which is applied in the field of building materials to achieve the effects of reducing maintenance costs, improving bending resistance and reducing self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

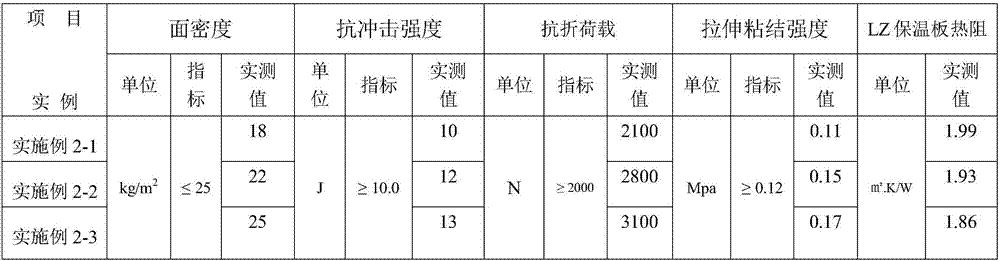

Examples

Embodiment 1

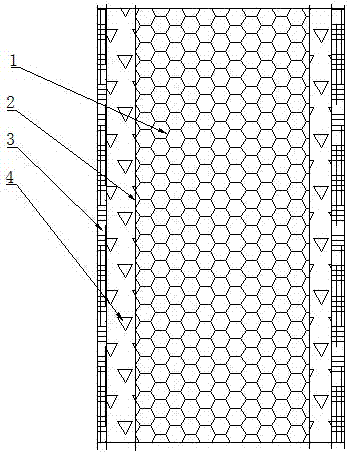

[0029] The lightweight reinforced composite insulation board of the present invention is an integral board member formed by extruding an XPS insulation layer 1, a steel wire skeleton 2, an alkali-resistant glass fiber mesh cloth 3 and a polystyrene particle slurry layer 4, and the XPS insulation Layer 1 is the core material, the steel wire skeleton 2 is set on the outside of the XPS insulation layer 1, the polystyrene particle slurry layer 4 is wrapped on the outside of the steel wire skeleton 2, and the alkali-resistant glass fiber mesh cloth 3 is arranged on the side of the steel wire skeleton 2. The XPS insulation layer 1 adopts rigid polystyrene foam plastics with closed-cell structure that is heated and extruded. Steel wire skeleton 2 adopts galvanized steel wire. The polyphenylene particle slurry layer 4 is provided with two layers, and the XPS insulation layer 1 is provided with one layer. The front, rear, left, and right edges of the polystyrene particle slurry layer 4...

Embodiment 2

[0047] The manufacturing method of the lightweight reinforced composite insulation board of the present invention, the manufacturing method comprises the following steps:

[0048] (1), preparation of polyphenylene particle slurry layer

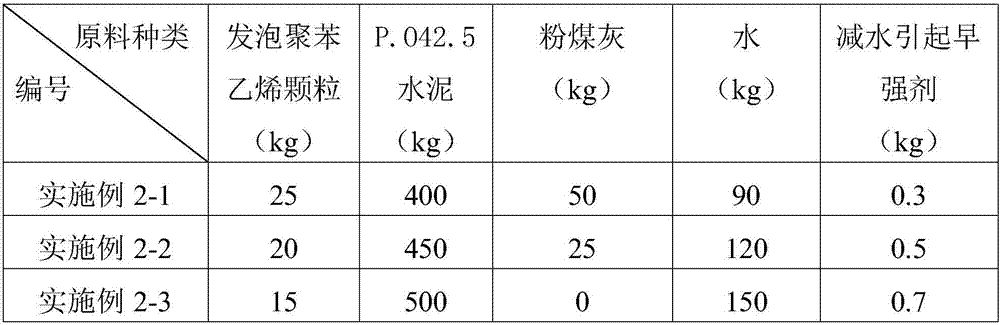

[0049] ①. Put expanded polystyrene particles, P.O42.5 cement, fly ash, water, and water-reducing early-strength agent into the mixer, and mix and stir evenly to make a mixed slurry; the water-reducing air-entraining early-strength agent is Composed of polycarboxylate complex alkyl and alkyl aromatic hydrogen sulfonates, expanded polystyrene particles are a mixture of irregular expanded polystyrene particles and spherical expanded polystyrene particles;

[0050] Wherein, the weight ratio of each raw material is shown in the following table:

[0051]

[0052] ②. Pass the mixed slurry into two temporary storage bins through two scrapers;

[0053] ③. When the mixed slurry in the temporary storage bin passes through the formwork, it is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com