Bone scaffold material, with shape memory function, for jaw repair and preparation method thereof

A bone scaffold and jawbone technology, applied in the field of bone scaffold material with shape memory function and its preparation, can solve the problems of low radiation cross-linking efficiency, PCL tensile strength and elongation at break and other mechanical properties decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Bone Scaffold Preparation

[0024] 1) Stir and dissolve PCL, PBS and PLGA in dioxane, stir at 40°C at high speed to dissolve fully, and obtain a clear solution; the total concentration of PCL, PBS and PLGA is 0.2g / ml;

[0025] 2) Make TCP powder, NaCl particles with a particle size (diameter) of 450-500 μm and NaHCO with a particle size (diameter) of 75-100 μm 3 Add the particles to the solution in step 1, ultrasonically disperse the inorganic matter evenly, and freeze overnight at -20°C to obtain a solid; porogens are NaCl and NaHCO 3 , the weight ratio is 1:1, the total weight of PCL, PBS and PLGA is 1 / 4 of the porogen;

[0026] 3) Place the solid in an absolute ethanol solution at -20°C for 12 hours and in a hydrochloric acid solution with a pH of 5 for 24 hours, and finally immerse the solid in double distilled water, change the water every 12 hours, take it out after 6 days, and freeze Serve dry. In the bone scaffold material, PCL is 100 parts by weight, PBS is ...

Embodiment 2

[0029] Bone Scaffold Preparation

[0030] 1) Stir and dissolve PCL, PBS and PLGA in dioxane, stir at 40°C at high speed to dissolve fully, and obtain a clear solution; the total concentration of PCL, PBS and PLGA is 0.2g / ml;

[0031] 2) Make TCP powder, NaCl particles with a particle size (diameter) of 450-500 μm and NaHCO with a particle size (diameter) of 75-100 μm 3 Add the particles to the solution in step 1, ultrasonically disperse the inorganic matter evenly, and freeze overnight at -20°C to obtain a solid; porogens are NaCl and NaHCO 3 , the weight ratio is 1:1, the total weight of PCL, PBS and PLGA is 1 / 4 of the porogen;

[0032]3) Place the solid in an absolute ethanol solution at -20°C for 12 hours and in a hydrochloric acid solution with a pH of 5 for 24 hours, and finally immerse the solid in double distilled water, change the water every 12 hours, take it out after 6 days, and freeze Serve dry. In the bone scaffold material, PCL is 100 parts by weight, PBS is 3...

Embodiment 3

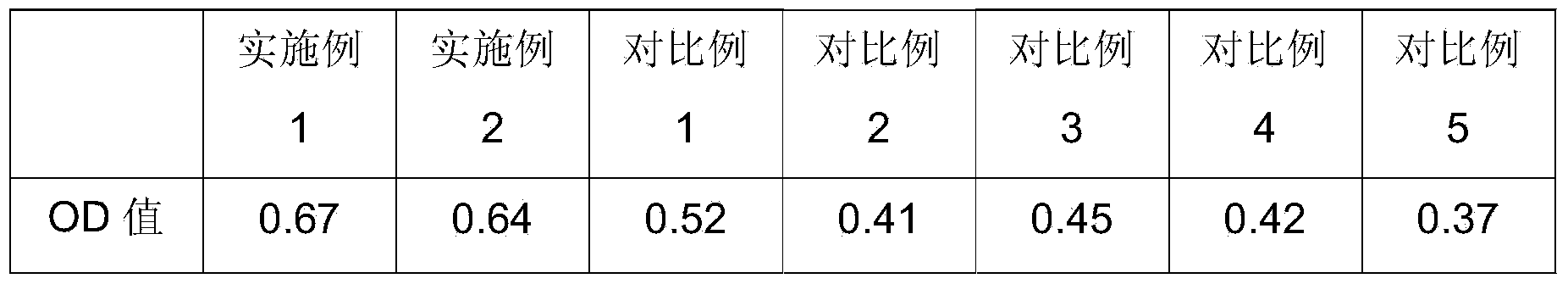

[0035] Effect of different weight ratios of PCL / PBS / PLGA / TCP on bone scaffold materials

[0036] Using PCL / PBS / PLGA / TCP with different weight ratios, bone scaffold materials were prepared respectively according to the method of Example 1, and the specific ratios were as follows:

[0037] parts by weight

PCL

PBS

PLGA

TCP

Comparative example 1

100

50

40

60

Comparative example 2

100

10

10

30

Comparative example 3

100

50

10

60

Comparative example 4

190

0

0

0

Comparative example 5

38

152

0

0

[0038] The tensile properties (tensile strength and bending strength) and shape recovery rate of bone scaffold materials were measured respectively:

[0039] Tensile properties refer to the national standard GB / T528-2009;

[0040] The method of measuring the shape recovery rate is to take a 10mm interval on the spline, mark it as L0, fix it for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com