Method for enabling bone cement to generate heat subsequently

A bone cement and subsequent technology, applied in medical science, prosthesis and other directions, can solve the problems of reduced polymerization heat temperature, poor treatment effect, limited tumor treatment effect, etc., achieving good biocompatibility and improving long-term efficacy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Group 1: 20g of acrylic resin bone cement powder and 0.5mg of gold nanorods were fully stirred and mixed, and 10ml of liquid material was added, fully stirred until the late stage of wire drawing or the early stage of dough, injected into a cylindrical mold with a diameter of 1.5cm, and the insertion test temperature range was 0~200℃ thermometer.

[0026] Group 2: 20g of acrylic resin bone cement powder was directly added to 10ml of acrylic resin bone cement liquid, and then injected into a cylindrical mold with a diameter of 1.5cm to form, and a thermometer with a temperature range of 0-200°C was inserted.

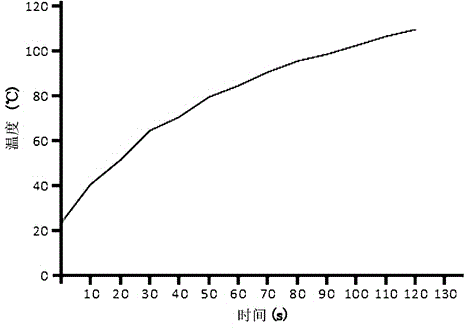

[0027] Record the temperature changes of the two respectively. For specific results, see figure 1 . The results showed that there was no difference between the bone cement with gold nanorods and ordinary bone cement, and the gold nanorods had no effect on the heat release of bone cement polymerization.

Embodiment 2

[0028] Example 2: In vitro temperature release of gold nanorods at different concentrations

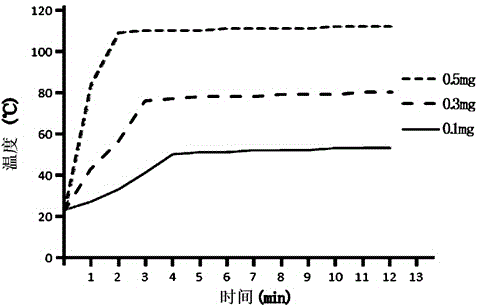

[0029] Mix 20g of acrylic resin bone cement powder with 0.1mg~0.6mg of gold nanorods to form a mixture; pour 10ml of acrylic resin bone cement liquid into the above mixture, stir well until the drawing stage or the early dough stage, and inject a diameter of A 1.5cm cylindrical mold was formed, and a thermometer with a test temperature range of 0-200°C was inserted; after the acrylic resin bone cement was cured for 24 hours, it was irradiated with infrared rays with a wavelength of 550 nm to 1550 nm. The gold nanorod has a diameter of 10-40nm and a length of 30nm-100nm. figure 2 The energy of the infrared light on the surface can be converted into heat by the nano-gold, which improves the polymerization heat temperature of the bone cement.

Embodiment 3

[0030] Example 3: The mechanical strength of different concentrations of gold nanorods and common bone cement

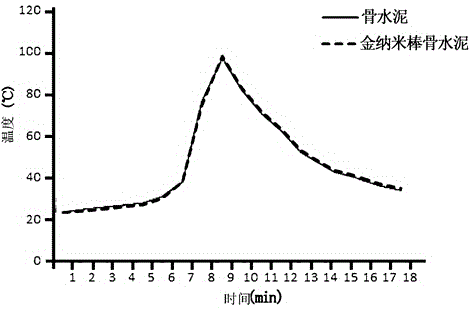

[0031] Mix 20g of acrylic resin bone cement powder with 0.1mg, 0.3mg and 0.5mg of gold nanorods, add 10ml of acrylic resin bone cement powder, stir well until the late drawing or early dough, and inject into a cylinder with a diameter of 1.5cm Shape the mold and insert a thermometer with a test temperature range of 0~200°C. After the acrylic resin bone cement is cured and cured for 24 hours, the infrared laser generator and the acrylic resin bone cement block are irradiated at a distance of 15cm, and the temperature changes of the three are shown in image 3 . The results showed that the rate and degree of temperature increase of acrylic resin bone cement were closely related to the amount of gold nanorods added. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com