Method for preparing stainless steel cutting cold saw and saw blade of cold saw

A technology of stainless steel and cold sawing, which is applied to the manufacture of knives of sawing machine devices, metal sawing equipment, and knives of sawing machine devices. It can solve the problems of limited spraying effect of saw blades, uneven stress of saw blades, and reduced friction coefficient. To achieve the effect of increased life, improved anti-sticking performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

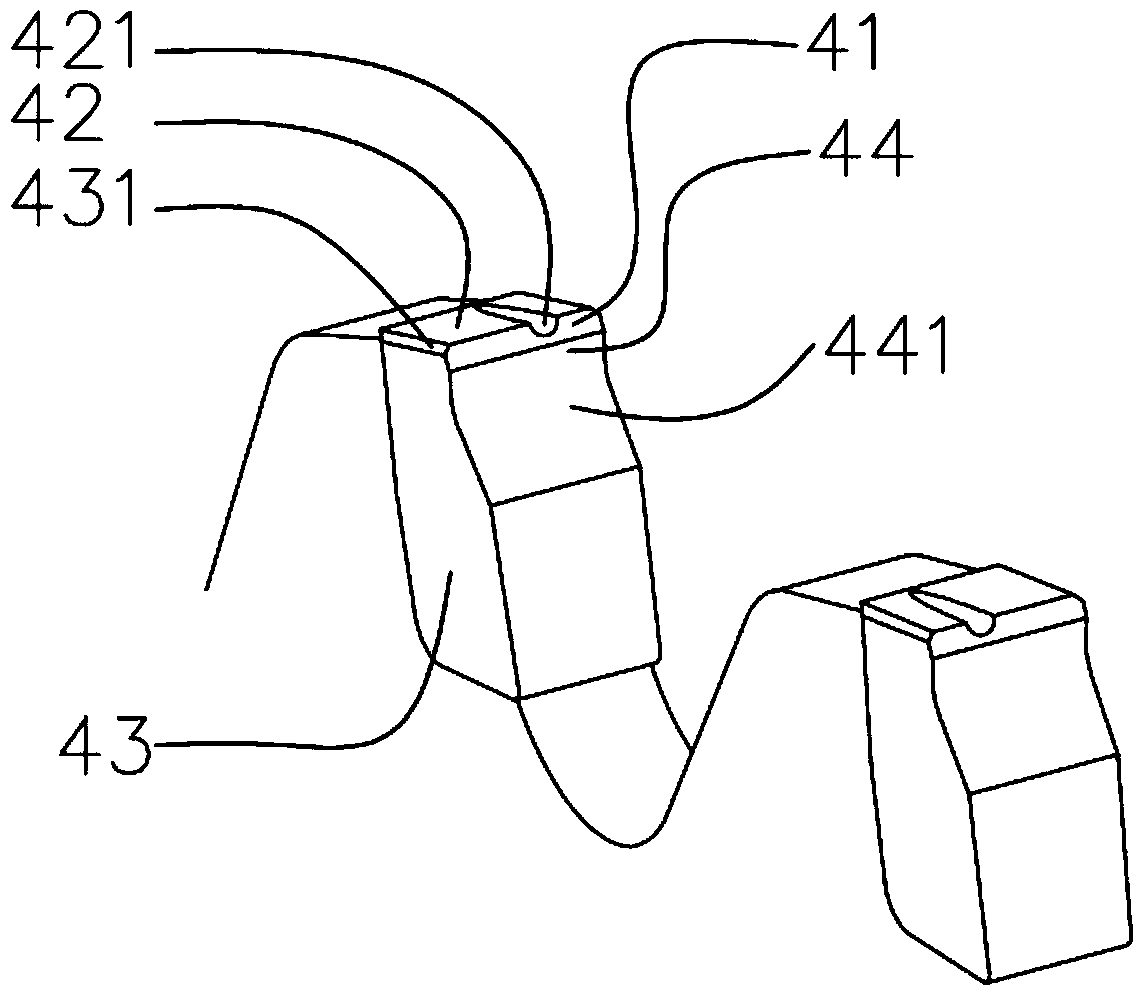

[0037] Embodiment 1 A kind of preparation method process of cold saw for cutting stainless steel of the present invention (take 285mm outer diameter, 2.0mm blade thickness, 1.7mm table thickness, 32mm inner hole, 80Z teeth as example): cermet cutter head side 43 is oiled Processed by cold grinding equipment, roughness Ra≤0.20μm, processed side angle, side protrusion, the height of the teeth near the rake face relative to the welding surface is between 0.02 ~ 0.03mm; near the tool tip relative to the welding surface At the bottom tooth width, the protrusion is between 0.07 and 0.10mm; on the chip guide 441 side, the radial rake angle is 7°, the included angle of the chip guide is 140°, and the R angle of the chip guide is greater than R0.7mm; the chip breaker 421 side, width 0.35mm, groove center distance 0.80mm, groove depth 0.18mm; anti-chip edge 431 side, 45° bevel angle, left-right symmetry, width 0.95mm, left-right symmetry less than 0.03mm; cutting edge 41 width 0.15mm, a...

Embodiment 2

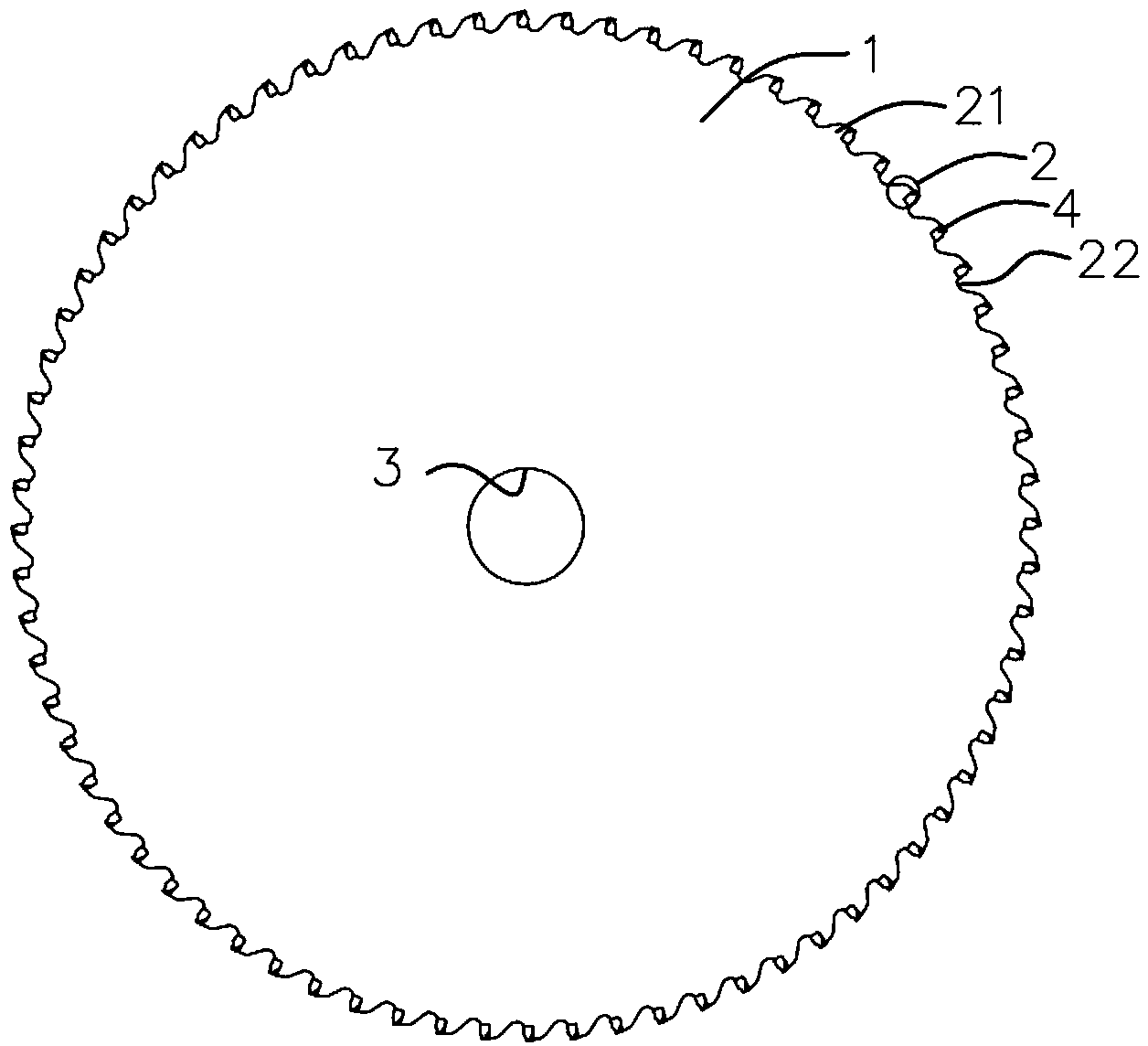

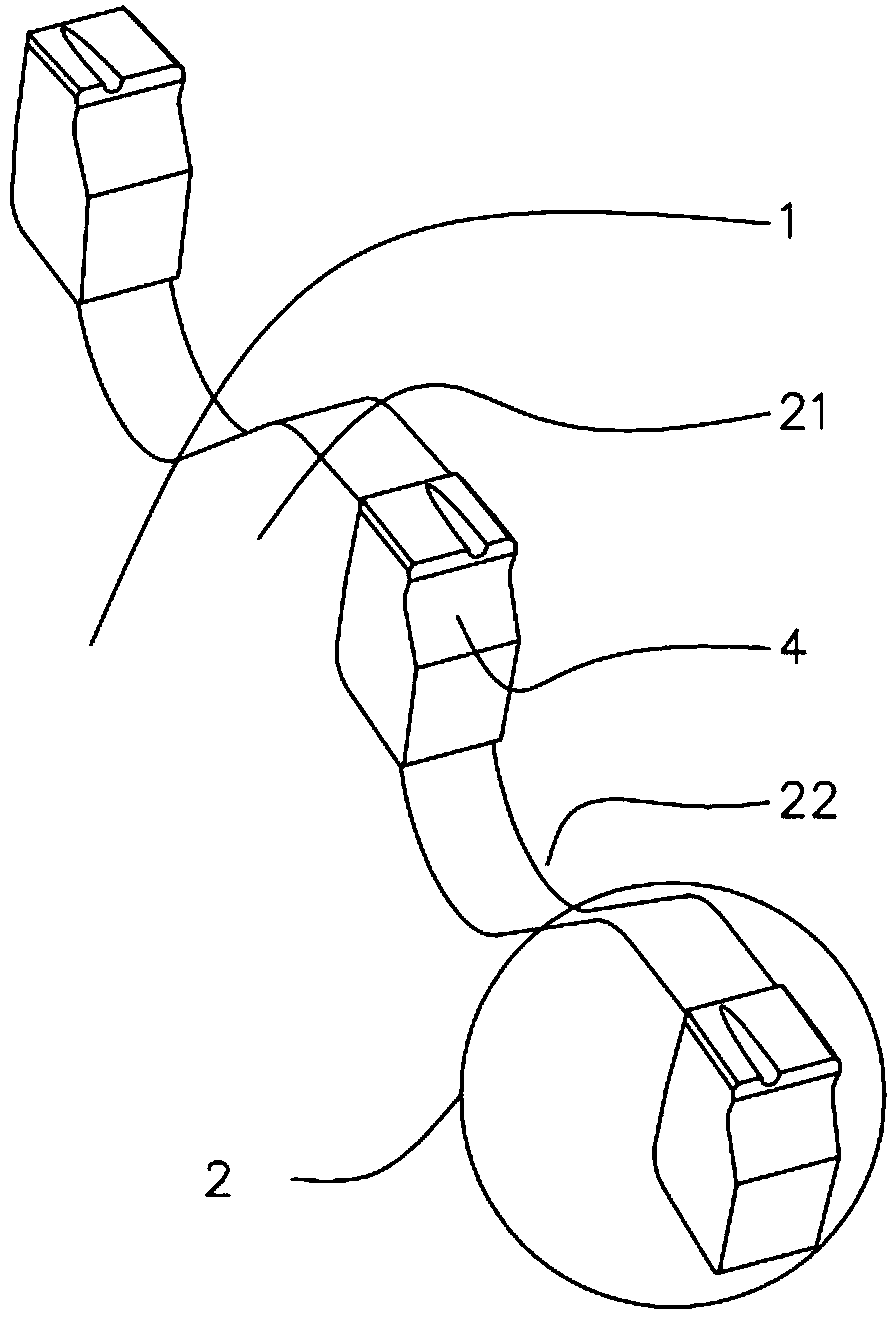

[0038] Example 2 A saw blade constructed according to the preparation method for cutting stainless steel cold saw described in Example 1, including a saw blade base 1, saw teeth 2 arranged on the circumference of the saw blade base 1, and mounting holes 3 arranged on the saw blade base The saw blade base 1 between adjacent saw teeth 2 is provided with a tooth bottom chip groove 22 connected to the tooth back 21 of the saw teeth 2, and the saw tooth 2 facing the cutting direction is installed on the tooth seat of the saw blade base 1. 4, and the cutting edge 41 of the serrated cutter head 4 faces the cutting direction, the flank 42 of the serrated cutter head 4 is provided with a chip breaker 421, and the flank 42 of the serrated cutter head 4 and the upper main An anti-chipping edge 431 is cut out at the intersection of the side surfaces 43, the cutting edge 41 is set at the intersection of the rake face 44 and the flank face 42, and a guide chip is set on the rake face 44 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com