Ultrahigh-barrier transparent aluminum oxide plated thin film and manufacturing method thereof

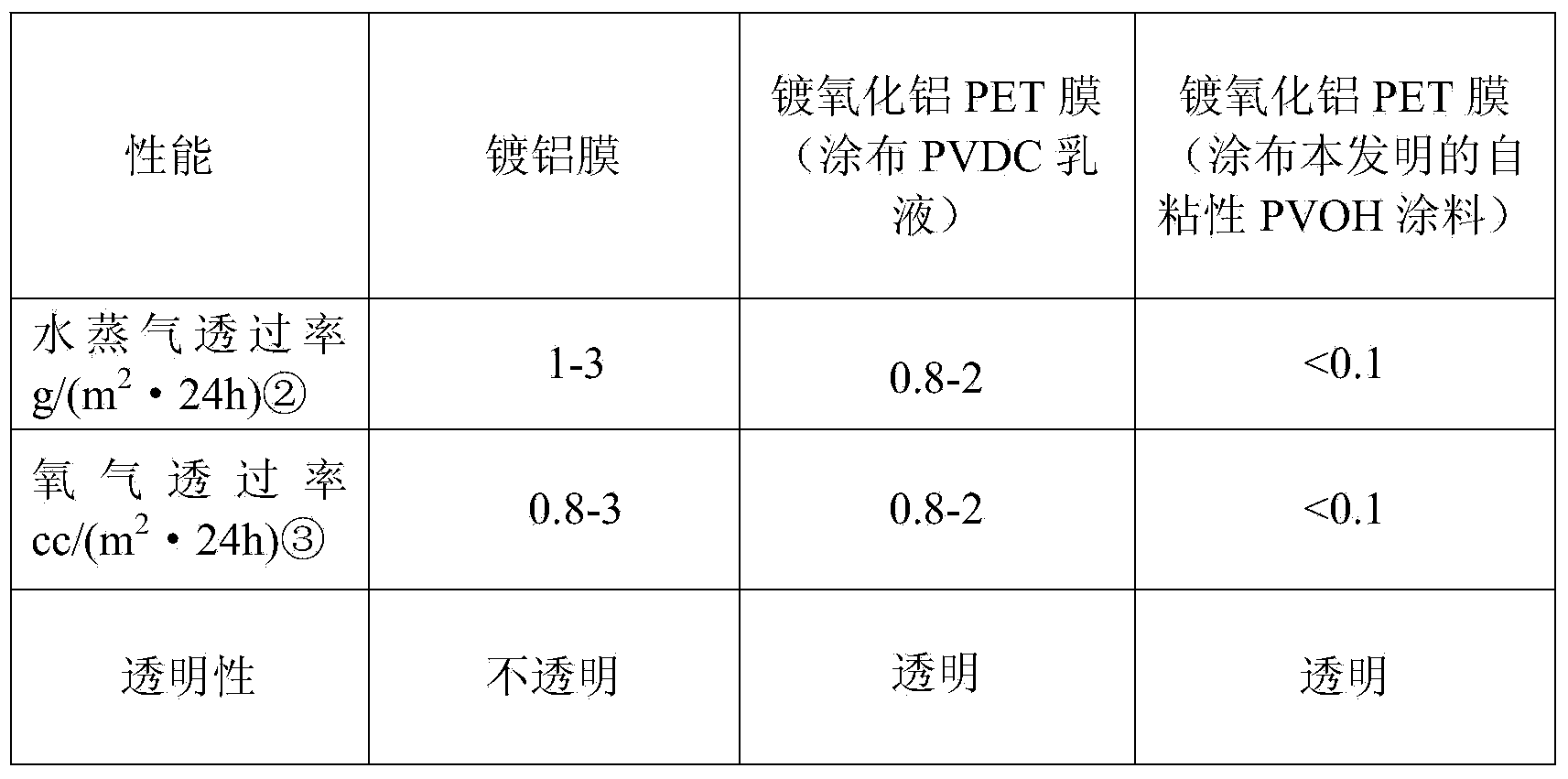

A technology for plating aluminum oxide and aluminum oxide layer, which is applied in the field of new polymer materials, can solve problems such as insufficient adhesion, and achieve the effects of reducing coating costs, reducing energy consumption, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of self-adhesive PVOH coating

[0035] Mix and stir 19% polyvinyl alcohol and 75% deionized water into the reaction kettle, gradually raise the temperature to 89°C, turn on the stirring device, set the stirring speed to 110 rpm, stir for 15 minutes, keep the constant temperature for 2.8 hours after stirring, add 0.002% silicone defoamer, cool down to 45°C, then add 0.018% sodium dodecylbenzenesulfonate, slowly add 0.08% lauric acid and 1.2% methyl etherified melamine resin dropwise, control the dropping rate within 2 hours After the addition, keep it for 1.5 hours after the dropwise addition, then add 4.7% polyethyleneimine, raise the temperature to 70°C and stir for 2.5 hours, after cooling down to room temperature, filter and discharge the material to obtain a self-adhesive PVOH coating with a solid content of 25%.

[0036] 2. Manufacture of aluminum oxide film

[0037] Place the reel of PET substrate film in the vacuum chamber, close the vacuum chambe...

Embodiment 2

[0040] 1. Preparation of self-adhesive PVOH coating

[0041] Mix and stir 14% polyvinyl alcohol and 82% deionized water into the reaction kettle, gradually raise the temperature to 88°C, turn on the stirring device, set the stirring speed to 100 rpm, stir for 17 minutes, keep the constant temperature for 2.5 hours after stirring, add 0.004% silicone defoamer, cool down to 47°C, then add 0.026% sodium dodecylbenzenesulfonate, slowly add 0.04% lauric acid and 1.93% methyl etherified melamine resin dropwise, control the dropping rate within 2 hours After the addition, keep for 1 hour after the dropwise addition, then add 2% polyethyleneimine, raise the temperature to 80°C and stir for 2.5 hours, cool down to room temperature, filter and discharge, and obtain a self-adhesive PVOH coating with a solid content of 18%.

[0042] 2. Manufacture of aluminum oxide film

[0043] Place the reel of PET substrate film in the vacuum chamber, close the vacuum chamber to evacuate, when the vac...

Embodiment 3

[0046] 1. Preparation of self-adhesive PVOH coating

[0047] Mix and stir 16% polyvinyl alcohol and 77.1% deionized water into the reaction kettle, gradually raise the temperature to 90°C, turn on the stirring device, set the stirring speed to 130 rpm, stir for 20 minutes, keep the constant temperature for 3.2 hours after stirring, add 0.002% silicone defoamer, cool down to 46°C, then add 0.018% sodium dodecylbenzenesulfonate, slowly add 0.08% lauric acid and 1.8% methyl etherified melamine resin dropwise, control the dropping rate within 2 hours After the addition was completed, keep it for 1.3 hours after the dropwise addition, then add 5% polyethyleneimine, raise the temperature to 72°C and stir for 2.5 hours, after cooling down to room temperature, filter and discharge the material to obtain a self-adhesive PVOH coating with a solid content of 22.9%.

[0048] 2. Manufacture of aluminum oxide film

[0049] Place the reel of PET substrate film in the vacuum chamber, close t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com