Aliphatic-polylactic acid segmented copolymer

A multi-block copolymer and aliphatic technology, which is applied in the field of aliphatic-polylactic acid multi-block copolymers, can solve the problems of poor mechanical properties, elongation at break can only reach 60%, and is not easy to degrade and change color , Reduce production cost, good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

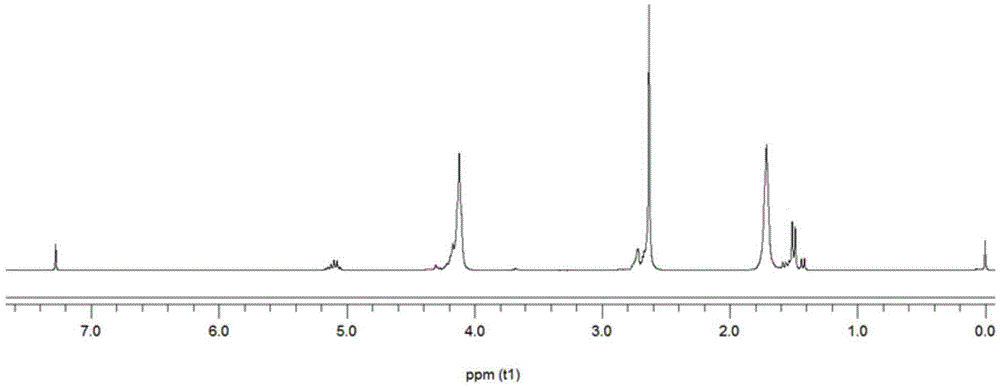

[0166] 1.1 The reaction kettle is cooled by repeated vacuuming and filling with inert gas. In the case of nitrogen gas, add 5000g lactide, 124g propylene glycol and 2g stannous octoate, seal the system, and put it into an oil bath preheated to 130°C , stirred for 24 hours to stop the reaction, vacuumed to remove unreacted monomers, and the pressure was 700Pa to obtain double-terminated hydroxyl polylactic acid;

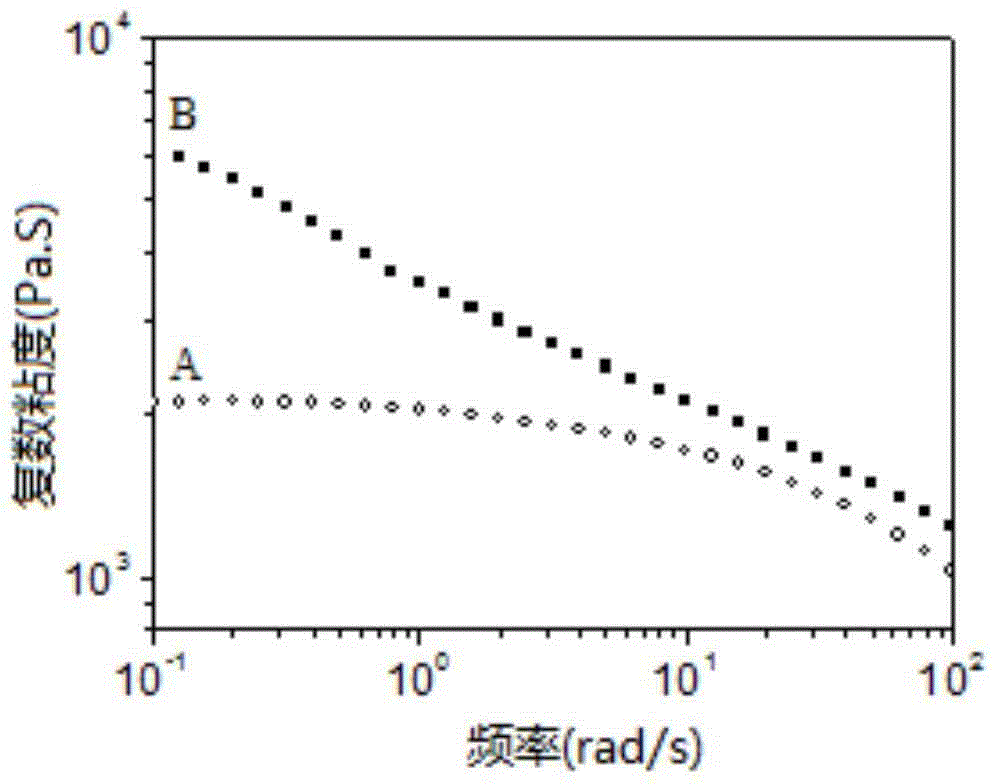

[0167] 1.2 After adding 580g of succinic acid, 500g of butanediol, 3g of glycerin, 1g of tetrabutyl titanate and 240g of double-terminated hydroxyl polylactic acid obtained in Example 1.1 into the reactor, the temperature of the reactor was raised to 150 ℃ and stir the reactants, and collect the water generated by the reaction at the same time. When the reaction no longer has liquid distilled out, set the reaction temperature to 255 ℃, gradually increase the temperature of the system, and vacuumize the polycondensation reaction when it reaches 255 ℃, gradually Reduce ...

Embodiment 2

[0173] Add 500g of succinic anhydride, 500g of butanediol, 1g of glycerol, 1g of tetrabutyl titanate and 120g of double-terminated hydroxyl polylactic acid obtained in Example 1.1 into the reactor in sequence, and raise the temperature of the reactor to 150°C And the reactant is stirred, and the water generated by the reaction is collected at the same time. When the reaction no longer has liquid distillation, the reaction temperature is set to 220 ° C, and the temperature of the system is gradually increased. Press to a high vacuum state, the pressure is 20Pa, polycondensation reaction is carried out, and the material is discharged for 15 hours to obtain polybutylene succinate-polylactic acid multi-block copolymer; the relative number average molecular weight is 20.0kg / mol.

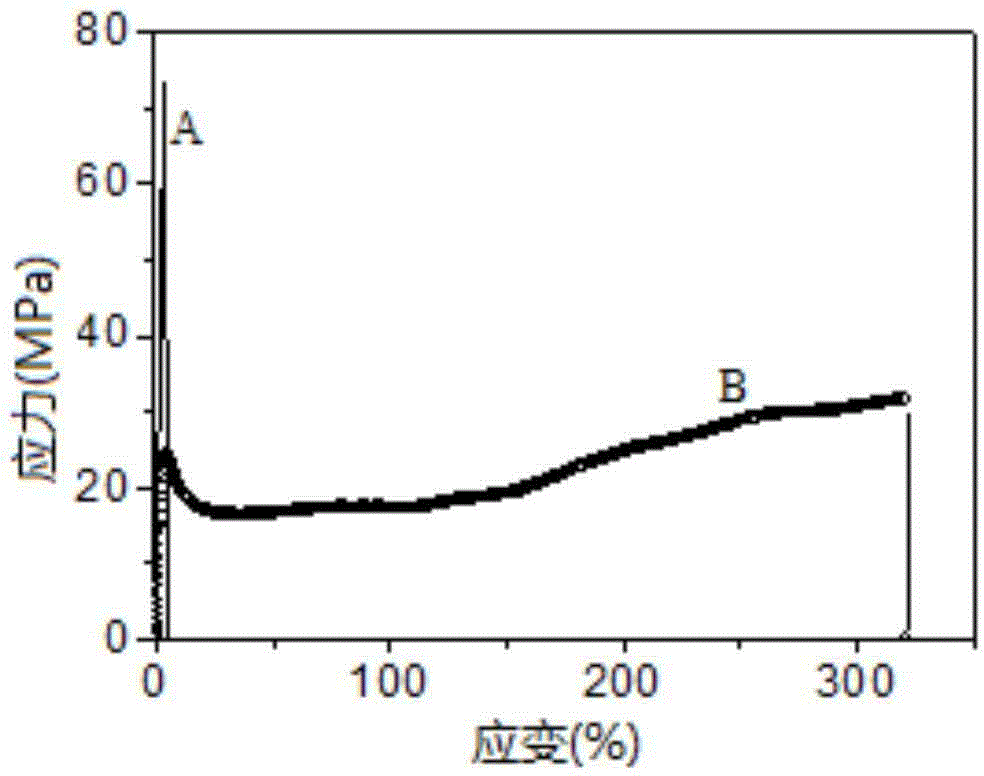

[0174] The present invention tests the mechanical properties of the product according to the above-mentioned technical scheme, and the test results show that the elongation at break of the polybutylene suc...

Embodiment 3

[0176] After adding 850g dimethyl adipate, 500g butanediol, 1g glycerin, 1g tetrabutyl titanate and 240g of the double-terminated hydroxyl polylactic acid obtained in Example 1.1 to the reactor, the temperature of the reactor was increased to make it Stir the reactants at 150°C, and collect the water generated by the reaction at the same time. When the reaction no longer distills liquid, set the reaction temperature to 220°C, gradually increase the temperature of the system, and vacuumize the polycondensation reaction when it reaches 220°C , gradually decompressed to a high vacuum state, the pressure was 10Pa, polycondensation reaction was carried out, and the material was discharged for 15 hours to obtain polybutylene adipate-polylactic acid multi-block copolymer; the relative number average molecular weight was 27.0kg / mol.

[0177] The present invention tests the mechanical properties of the product according to the above-mentioned technical scheme, and the test results show ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com