Ultraviolet-aging-resistant SBR (styrene butadiene rubber) modified asphalt and preparation method thereof

A modified asphalt, UV-resistant technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of SBS modified asphalt structure and performance, difficult to mix, poor road traffic capacity, etc., to avoid precipitation and segregation, improve high and low temperature performance, and reduce the effect of collision agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

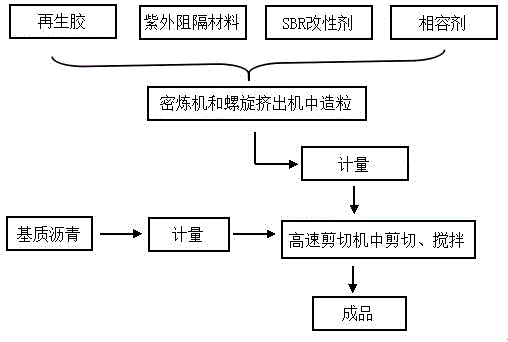

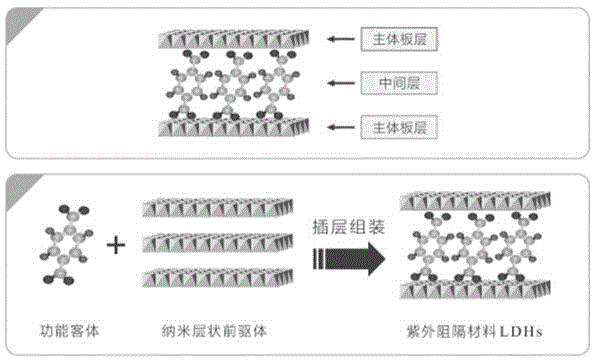

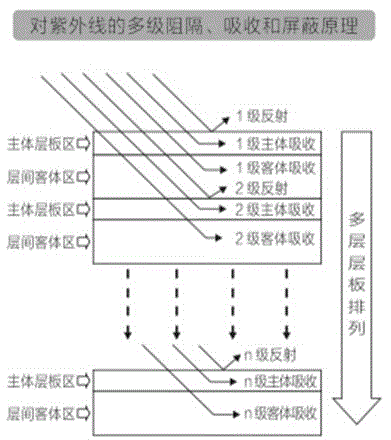

[0038] The raw materials were weighed according to the weight of the following components: 2 kg of magnesium-aluminum layered double hydroxide UV barrier material, 2 kg of reclaimed rubber, 1 kg of compatibilizer, and 2 kg of styrene-butadiene rubber, of which the magnesium-aluminum layered double hydroxide UV barrier material was produced by Jiangyin Produced by Ruifa Chemical Company, the magnesium-aluminum layered double hydroxide UV barrier material consists of magnesium-aluminum double hydroxide laminates and interlayer carbonates to form a multi-level layered structure, which belongs to anionic layered clay and belongs to Hexagonal crystal system, the specific composition is Mg 1-X al X (OH) 2 (CO 3 ) X / 2 mH 2 O, where the subscript X refers to the change of the content of metal elements, 0.2≤X≤0.33; m value represents the amount of crystal water, 0≤m≤2. Put the above-mentioned raw materials into a high internal mixer for internal mixing for 20 minutes; the temperat...

specific Embodiment 2

[0044] The raw materials were weighed according to the weight of the following components: 1.5 kg of magnesium-aluminum layered double hydroxide UV barrier material, 2 kg of reclaimed rubber, 1.6 kg of compatibilizer, and 1.8 kg of styrene-butadiene rubber, of which the magnesium-aluminum layered double hydroxide UV barrier The material is produced by Jiangyin Ruifa Chemical Co., Ltd. The magnesium-aluminum layered double hydroxide ultraviolet barrier material is composed of magnesium-aluminum double hydroxide laminates and interlayer carbonates to form a multi-level layered structure, which belongs to anionic layered Clay, belonging to the hexagonal crystal system, the specific composition is Mg 1-X al X (OH) 2 (CO 3 ) X / 2 mH 2 O, where the subscript X refers to the change of the content of metal elements, 0.2≤X≤0.33; m value represents the amount of crystal water, 0≤m≤2. The above-mentioned raw materials were put into a high internal mixer for internal mixing for 25 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uv intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com