Backlight module and liquid crystal display device

A technology of backlight module and liquid crystal display, applied in instruments, optics, nonlinear optics, etc., can solve the problems of reducing the ability of excited light, limiting the life of the backlight module, thick thickness of the backlight module, etc., to improve the uniformity , Simplify the structure and ensure the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

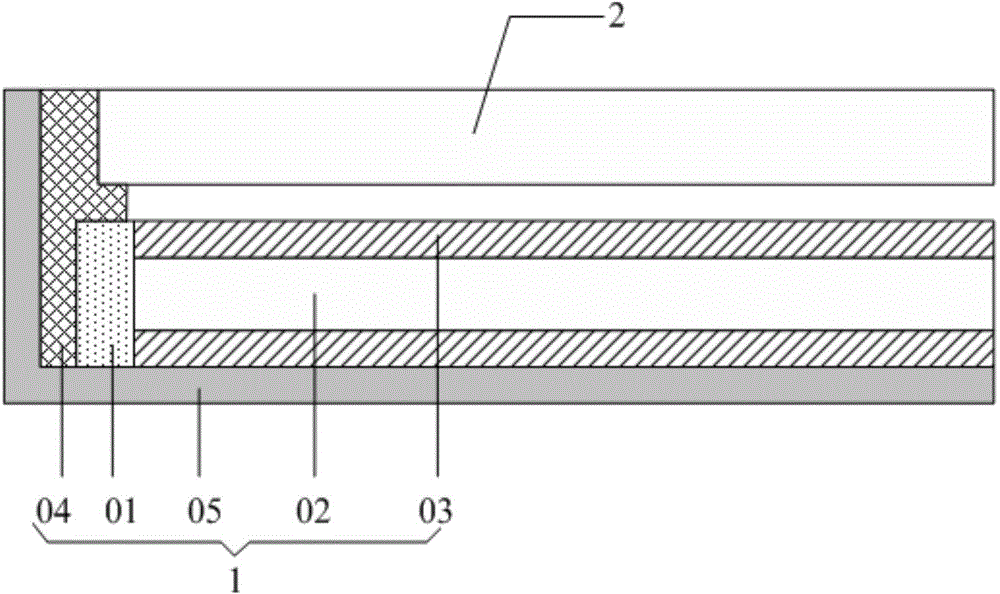

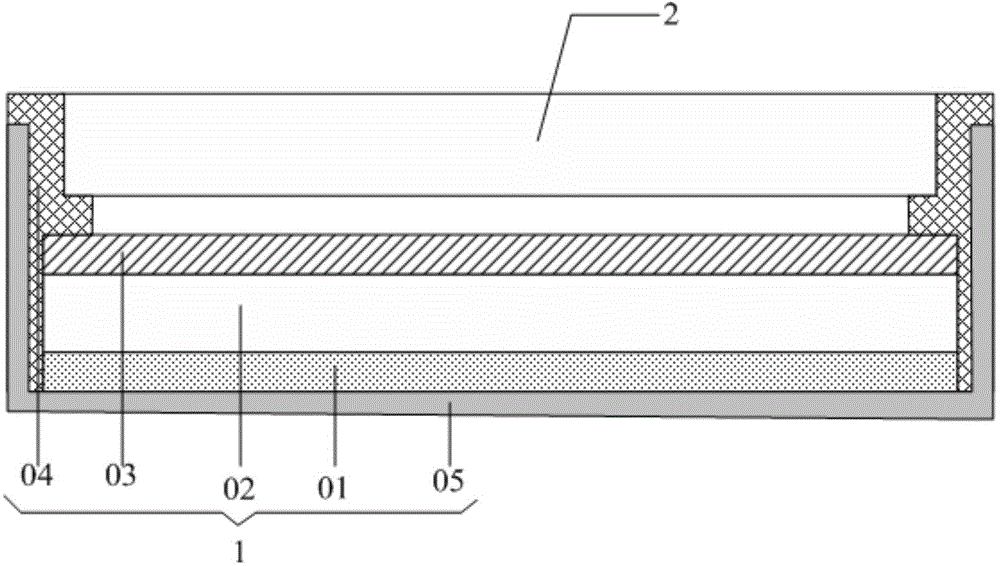

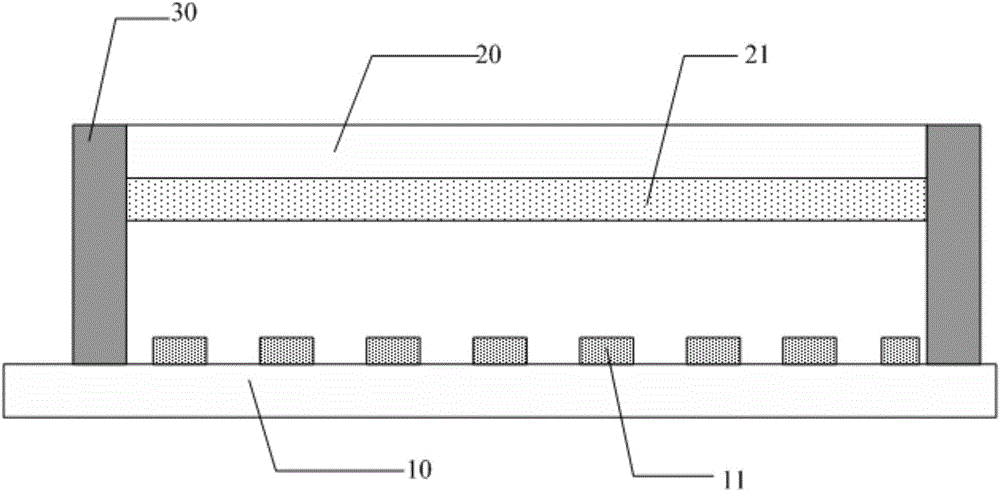

[0026] The specific implementation manners of the backlight module and the liquid crystal display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] The shape and size of each film layer in the drawings do not reflect the real proportion of the backlight module, and the purpose is only to illustrate the content of the present invention.

[0028] A backlight module provided by an embodiment of the present invention, such as figure 2 As shown, it includes: a first substrate 10 and a second substrate 20 arranged oppositely, an array of light emitting devices 11 located on the first substrate 10, and a driving circuit for driving the light emitting devices 11 to emit light ( figure 2 not shown in ), the phosphor layer 21 coated on the side of the second substrate 20 facing the first substrate 10, and the sealant frame 30 sealingly connecting the boundary of the first substrate 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com