Carbon battery sealing glue and preparation method thereof

A sealing glue and battery technology, applied in battery pack parts, battery boxes/jackets, circuits, etc., can solve the problems of high cost, easy aging of carbon battery sealing glue, inconvenient use, etc., and achieve low cost and experimental conditions. Mild, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

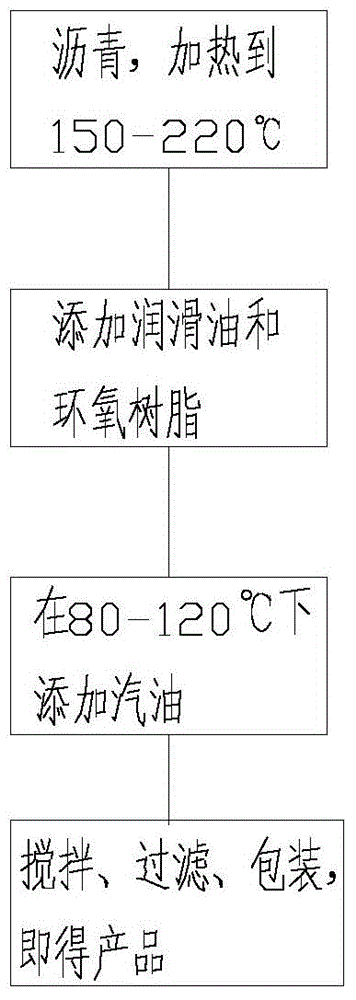

[0030] See attached figure 1 , a preparation method of carbon battery sealant, comprising the following steps:

[0031] 1) Heat the asphalt to 150-220°C, melt it, stir, and add lubricating oil and epoxy resin to obtain the crude product;

[0032] 2) When the temperature of the crude product obtained in step 1) drops to 80-120° C., add gasoline therein, stir evenly, wait for the water to volatilize, filter, pack, and obtain the product.

[0033] In the step 2), the gasoline addition rate is 1-4% of the total gasoline weight added per minute, the stirring speed is 50-120r / min, the stirring time is 10-200min, and the particle diameter of the filter screen is 200-400 mesh .

[0034] In the step 1), the temperature of the bitumen is 180-200°C, and the heating time is 2-48h.

Embodiment 1

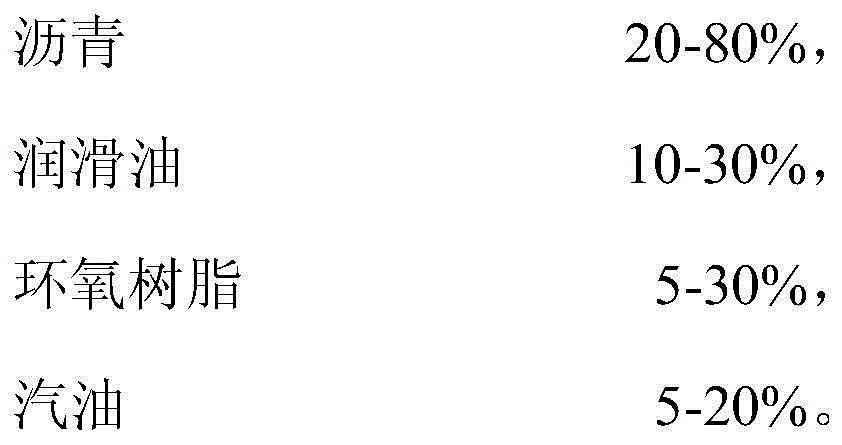

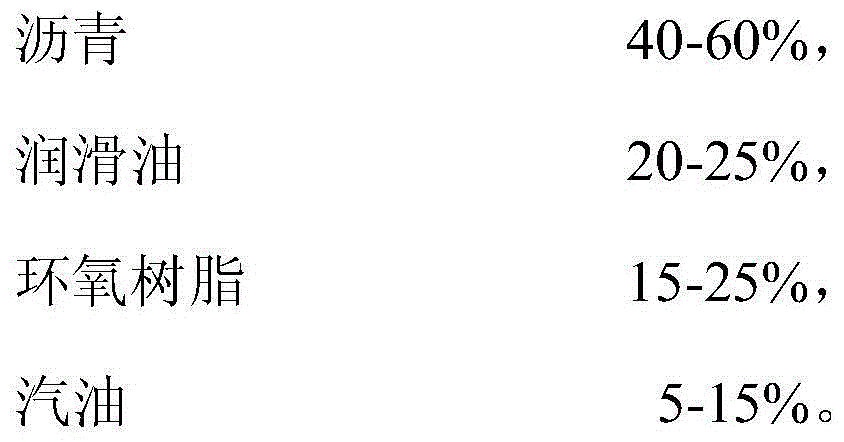

[0036] 1) prepare materials according to the following percentages by weight, modified asphalt 80%, lubricating oil 10%, epoxy resin 5% and gasoline 5%, wherein, gasoline is solvent gasoline, and the softening point of modified asphalt is 95 degrees;

[0037] 2) Heat the asphalt to 150°C for 12 hours to melt and stir, then turn off the heating and continue to add the lubricating oil and epoxy resin to obtain the crude product;

[0038] 3) When the temperature of the crude product obtained in step 1) drops to 80° C., slowly add the above-mentioned gasoline to it, stir evenly, and wait until no bubbles are generated on the surface, that is, the water is volatilized, filtered, and packaged to obtain the product.

[0039] The resulting sealing glue is composed of 80wt% asphalt, 10wt% lubricating oil, 5wt% epoxy resin and 5wt% gasoline. The sealing glue is applied to the sealing part of the carbon battery, and the sealing effect is good, and the aging resistance is good. It does no...

Embodiment 2

[0041] 1) prepare materials according to the following weight percentages, oxidized asphalt 60%, lubricating oil base oil 20%, epoxy resin 15% and gasoline 5%, wherein, the softening point of oxidized asphalt is 100 degrees;

[0042] 2) Heat the asphalt to 190°C for 48 hours to melt and stir, then turn off the heating and continue adding the above lubricating oil base oil and epoxy resin to obtain a crude product;

[0043] 3) When the temperature of the crude product obtained in step 1) drops to 100° C., slowly add the above-mentioned gasoline in it, the addition speed of gasoline is 1% of the total weight of gasoline added per minute, stir evenly, and stir at 50r / min Stir at high speed for 200 minutes to complete the evaporation of water, filter through a 200-mesh filter, and pack to obtain the product.

[0044] The resulting sealing glue is composed of 60wt% asphalt, 20wt% lubricating oil, 15wt% epoxy resin and 5wt% gasoline. The sealing glue is applied to the sealing part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com