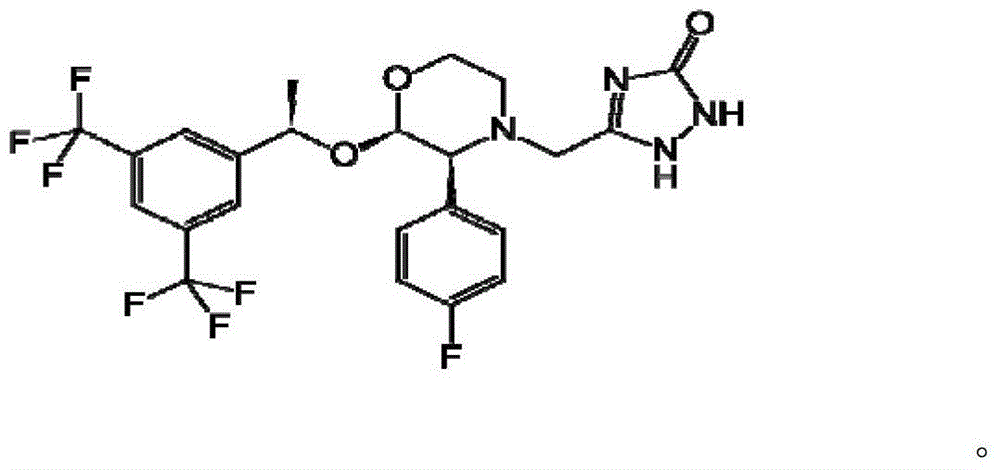

Aprepitant compound and its preparation method

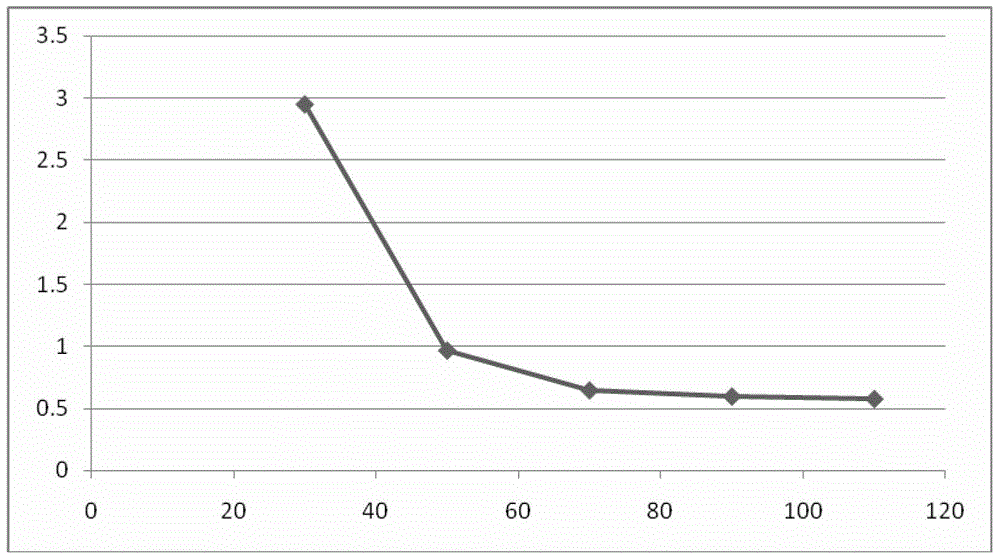

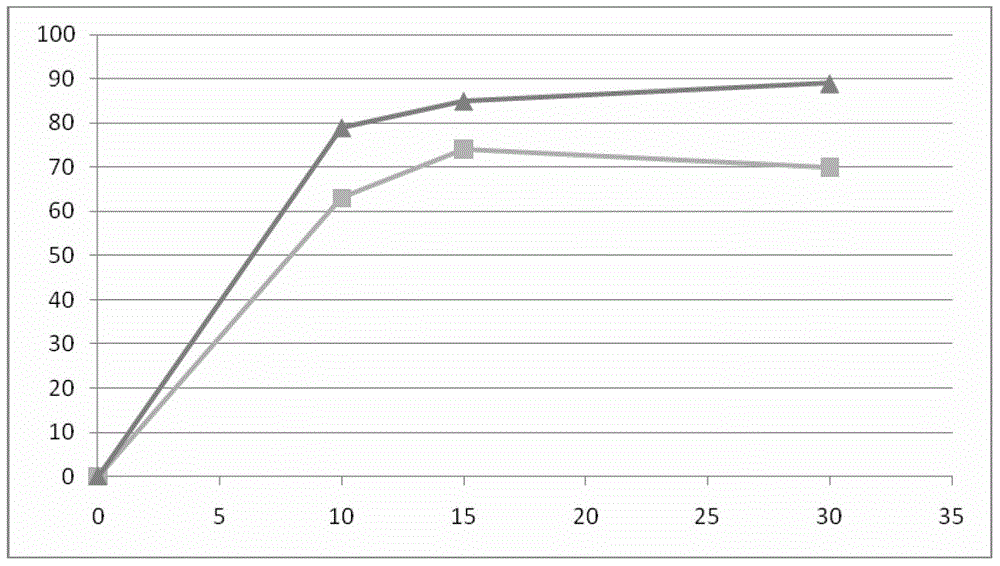

An aprepitant and compound technology, which is applied in the field of highly soluble aprepitant compound and its preparation, can solve the problems of fast elimination, difficult drug absorption, poor bioavailability, etc. Great clinical application value and the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of Aprepitant Complex

[0036] Aprepitant, sucrose and suspending agents hypromellose and poloxamer were wet milled.

[0037] formula:

[0038] name

[0039] *: Removed during process

[0040] preparation:

[0041] Connect the wet grinding machine ECM-AP 05 and the liquid distribution tank (with jacket and stirring paddle) to the water cooling system respectively, and the temperature of the cold water is 10°C. Aprepitant, Poloxamer F127 and Hypromellose E5 were mixed into a homogeneous solid mixture. Put another purified water in the liquid mixing tank, turn on the stirring, slowly add aprepitant, poloxamer F127 and hypromellose E5 into the above liquid mixing tank, and add while stirring to form a uniform mixture. Suspension, keep stirring, set aside. Connect the outlet of the liquid dispensing tank to the inlet of the wet grinder with a pipeline, connect the outlet of the wet grinder to the inlet of the liquid dispensing tank with ...

Embodiment 2

[0049] Aprepitant, fructose, and suspending agent, sodium carboxymethylcellulose, were wet milled.

[0050] formula:

[0051] name

[0052] Aprepitant

[0053] *: Removed during process

[0054] preparation:

[0055] Connect the wet grinding machine ECM-AP 05 and the liquid distribution tank (with jacket and stirring paddle) to the water cooling system, and the temperature of the cold water is 8 degrees. Mix aprepitant and sodium carboxymethylcellulose to form a homogeneous solid mixture. Weigh a certain amount of purified water into the liquid mixing tank, turn on the stirring, slowly add aprepitant and carboxymethylcellulose sodium into the above liquid mixing tank, add while stirring to form a uniform suspension, keep Stirring state, set aside. The above-mentioned liquid preparation tank is connected with the wet grinding machine with a pipeline, the grinding machine is turned on, the grinding administration speed is 3 L / min, and the grinding bead pa...

Embodiment 3

[0062] Aprepitant, dextrose and suspending agent hydroxyethylcellulose were wet milled.

[0063] formula:

[0064] name

[0065] *: Removed during process

[0066] preparation:

[0067] Connect the wet grinding machine ECM-AP 05 and the liquid distribution tank (with jacket and stirring paddle) to the water cooling system, and the temperature of the cold water is 7 degrees. Aprepitant and hydroxyethylcellulose were mixed into a homogeneous solid mixture. Weigh a certain amount of purified water into the liquid mixing tank, turn on the stirring, slowly add aprepitant and hydroxyethyl cellulose into the above liquid mixing tank, add while stirring to form a uniform suspension, keep stirring status, standby. Connect the above-mentioned liquid preparation tank to the wet grinder with a pipeline, turn on the grinder, grind the dosing speed to 4 L / min, and the grinding bead particle size is 0.1 mm. After the grinding starts, slowly add the prescribed amount of glucose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com