A kind of preparation method of silver phosphate-cadmium sulfide composite visible light photocatalyst

A technology of photocatalyst and cadmium sulfide, which is applied in the field of photocatalytic material preparation, can solve the problems of poor stability of silver phosphate photocatalyst and difficulty in controlling the morphology and structure, and achieve the advantages of large-scale production and preparation, abundant raw materials, cheap and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

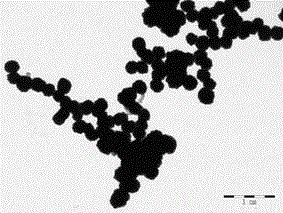

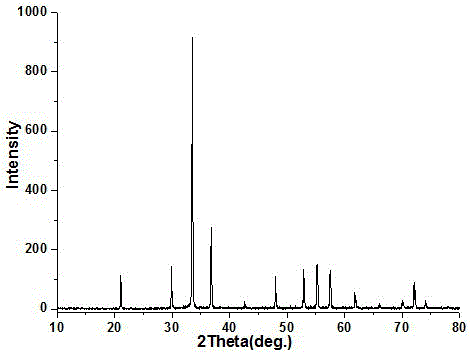

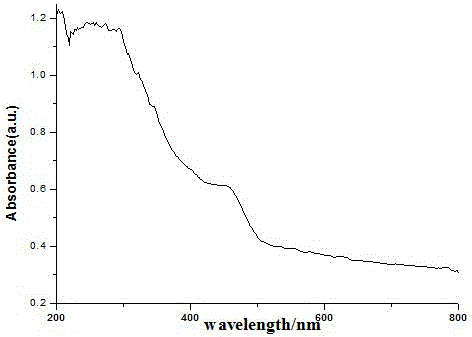

Embodiment 1

[0025] First, take trisodium citrate and dissolve it in deionized water to prepare 100 ml of a solution with a concentration of 0.1 moles per liter. Weigh 0.02 mole of cadmium sulfide and add it into the above solution, and sonicate for 10 minutes to form a uniformly dispersed turbid solution. Weigh 0.02 mole of silver nitrate and add it into the above mixed solution, and stir at room temperature for 10 minutes to obtain a silver-citric acid complex solution. At room temperature, 0.01 mol / L ammonium dihydrogen phosphate aqueous solution was added dropwise to the above mixed solution and vigorously stirred to obtain a yellow turbid solution. The obtained yellow-brown turbid liquid was centrifuged with a centrifuge, and after centrifuging at a speed of 4500 rpm for 10 minutes, the colorless solution in the centrifuge tube was removed to obtain a yellow precipitated product. The obtained yellow precipitate was washed ultrasonically with deionized water and washed at 50 o Drying...

Embodiment 2

[0027] First, take trisodium citrate and dissolve it in deionized water to prepare 100 ml of a solution with a concentration of 0.2 moles per liter. Weigh 0.04 mole of cadmium sulfide and add it to the above solution, and sonicate for 20 minutes to form a uniformly dispersed turbid solution. Weigh 0.04 moles of silver nitrate and add it into the above mixed solution, and stir at room temperature for 20 minutes to obtain a silver-citric acid complex solution. At room temperature, 0.015 mol / L ammonium dihydrogen phosphate aqueous solution was added dropwise to the above mixed solution and vigorously stirred to obtain a yellow turbid solution. The obtained yellow-brown turbid liquid was centrifuged with a centrifuge, and after centrifuging at a speed of 4000 rpm for 10 minutes, the colorless solution in the centrifuge tube was removed to obtain a yellow precipitated product. The obtained yellow precipitate was washed ultrasonically with deionized water and washed at 50 o Drying...

Embodiment 3

[0029] First, trisodium citrate was weighed and dissolved in deionized water to prepare 100 ml of a solution with a concentration of 0.3 moles per liter. Weigh 0.06 mole of cadmium sulfide and add it to the above solution, and sonicate for 10 minutes to form a uniformly dispersed turbid solution. Weigh 0.06 mol of silver nitrate and add it into the above mixed solution, and stir at room temperature for 10 minutes to obtain a silver-citric acid complex solution. At room temperature, 0.02 mol / L ammonium dihydrogen phosphate aqueous solution was added dropwise to the above mixed solution with vigorous stirring to obtain a yellow turbid solution. The obtained yellow-brown turbid liquid was centrifuged with a centrifuge, and after centrifuging at a speed of 3000 rpm for 10 minutes, the colorless solution in the centrifuge tube was removed to obtain a yellow precipitated product. The obtained yellow precipitate was washed ultrasonically with deionized water and washed at 50 o Dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com