Deep hydrodesulfurization catalyst preparation method by carrying nickel and tungsten on multistage porous zeolite

A desulfurization catalyst, deep hydrogenation technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low molecular catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

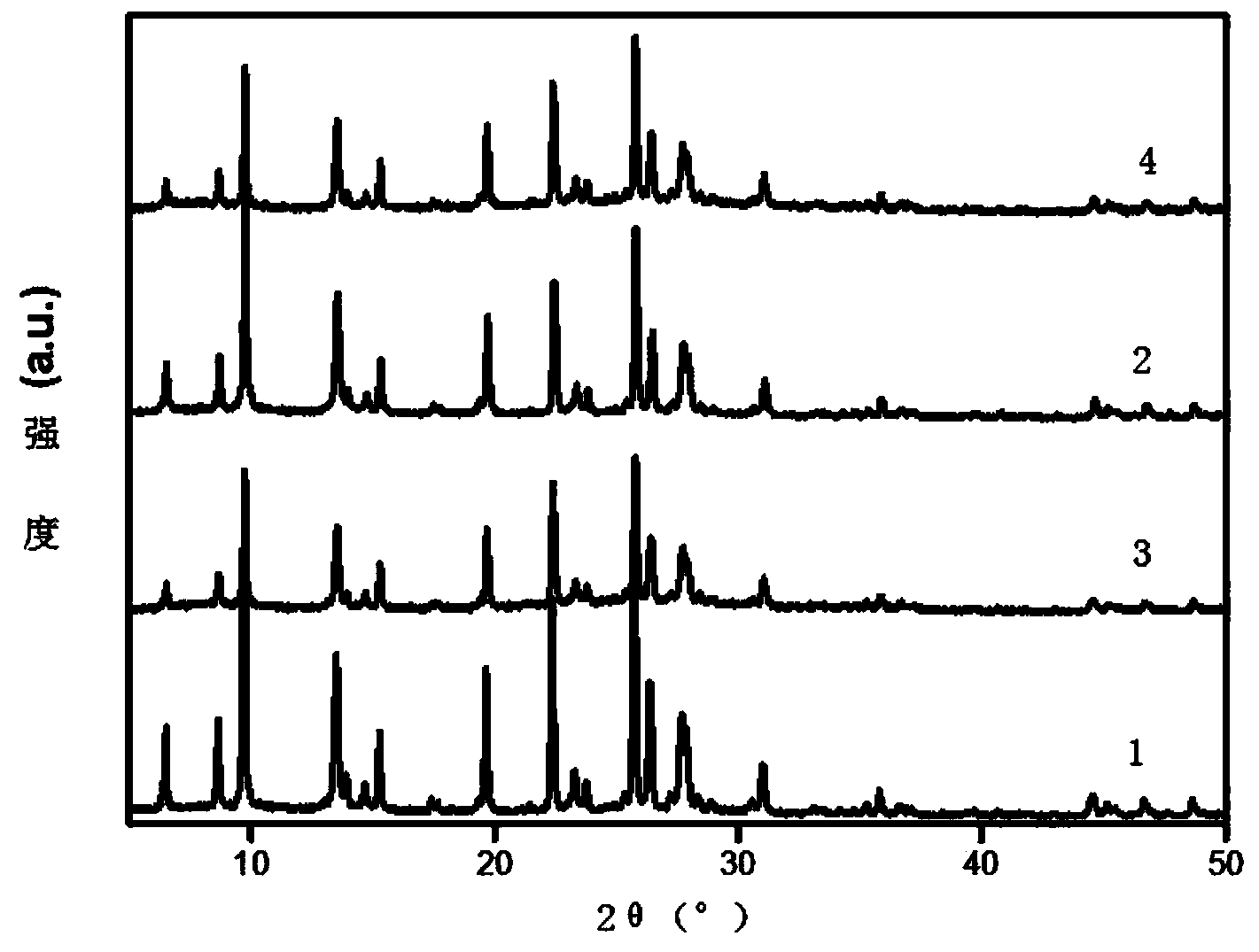

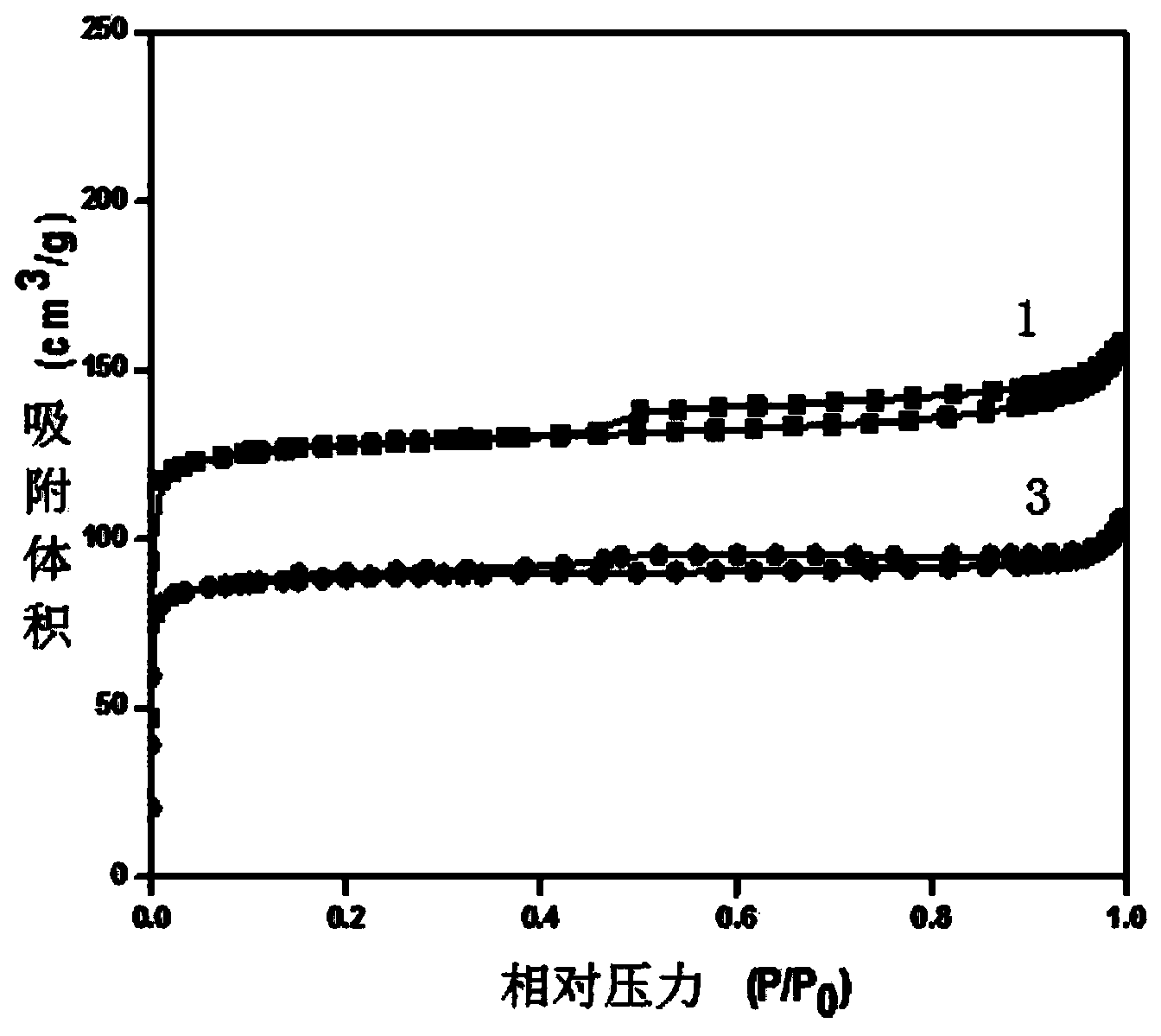

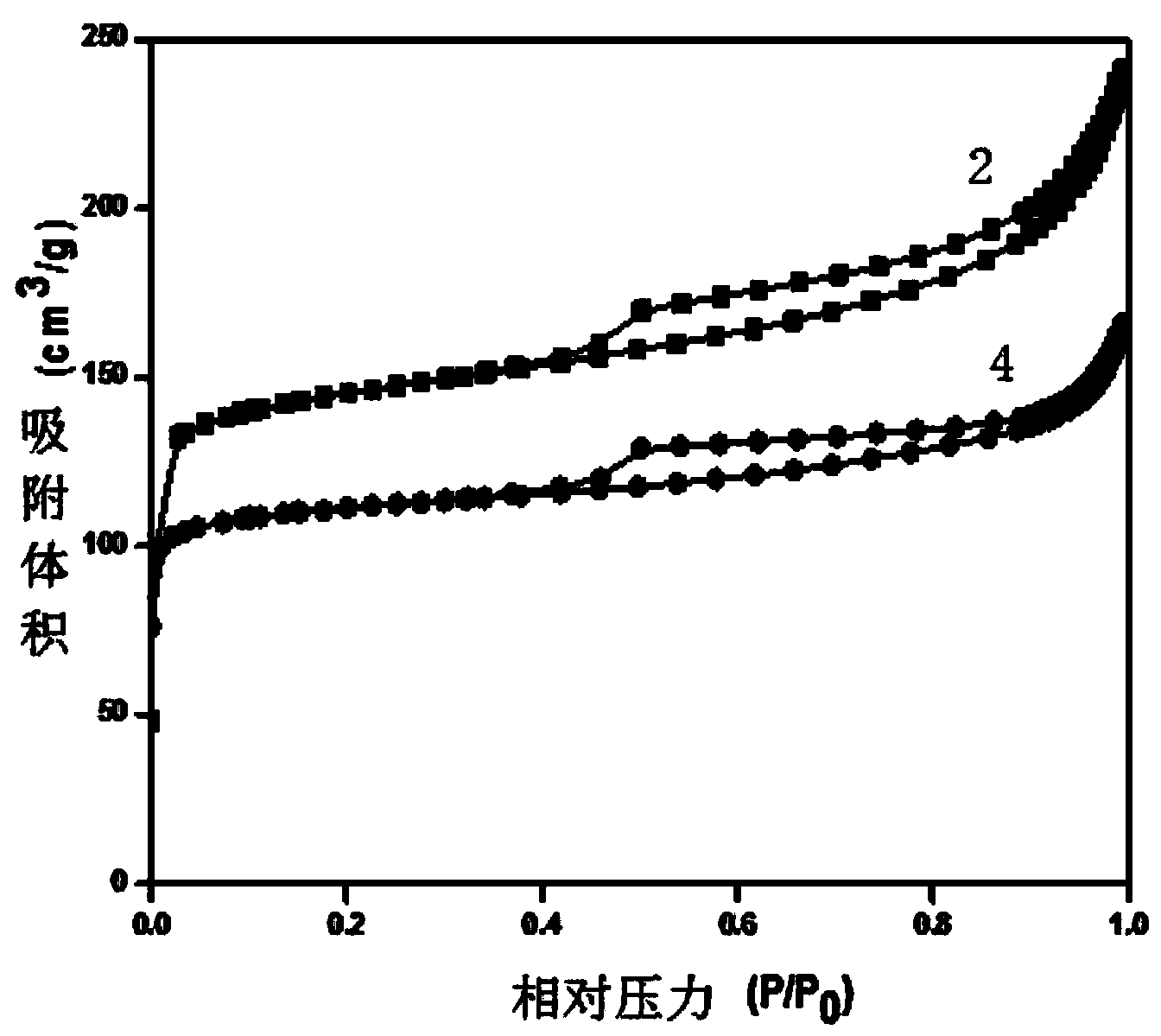

[0027] Specific implementation mode 1: The preparation method of nickel-tungsten deep hydrodesulfurization catalyst supported by hierarchical porous zeolite in this implementation mode is implemented according to the following steps:

[0028] 1. Calcining the zeolite at 500-600°C for 4.5-5.5 hours to obtain microporous hydrogen zeolite;

[0029] 2. Add the microporous hydrogen-type zeolite obtained in step 1 into the acid solution with a concentration of 0.1-4mol / L, heat and reflux for 0.5-4h, then wash with deionized water until the filtrate is neutral, and dry it at 500 Calcining at ~600°C for 4.5~5.5h to obtain dealuminated zeolite;

[0030]3. Add the dealuminated zeolite obtained in step 2 into the alkali solution with a concentration of 0.1-2mol / L, stir at 60-70°C for 0.2-3h, then wash with deionized water until the filtrate is neutral, and dry it Finally, use ammonium nitrate solution for ion exchange, and then calcine at 500-600°C for 4-6 hours to obtain hydrogen-type ...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment is different from Embodiment 1 in that Step 2 is heated to reflux at 60-70° C. for 0.5-4 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solid-to-liquid ratio of the microporous hydrogen zeolite to the acid solution in Step 2 is 1 g:30 mL. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com