Sewage treatment plant based on mechanical recompression technique

A sewage treatment device and mechanical recompression technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. The operator requires high difficulty, so as to achieve the effect of sewage treatment, convenient expansion and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

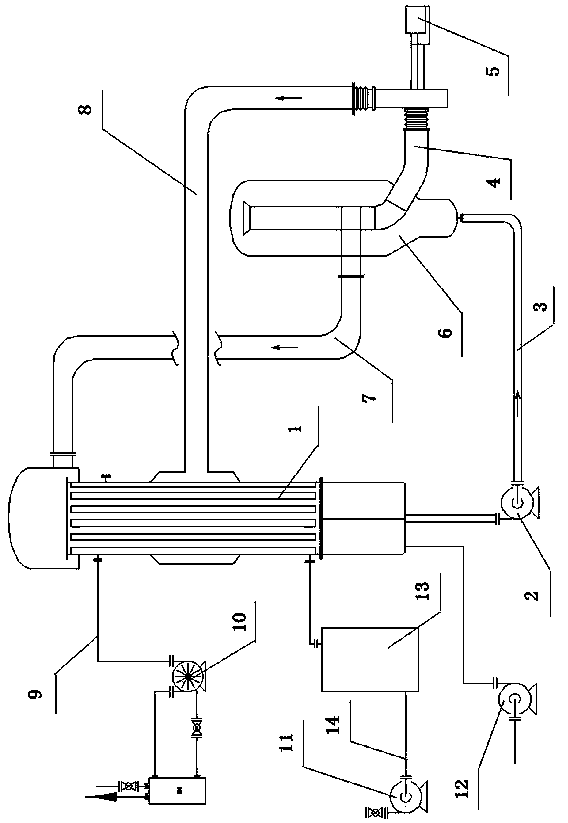

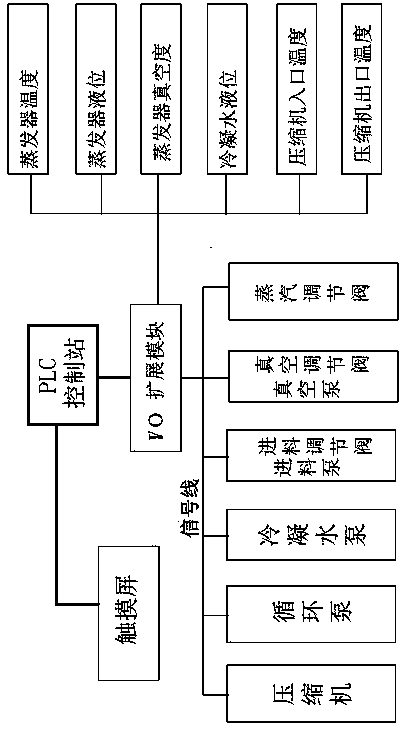

[0035] Embodiment 1, with reference to figure 1 -2. A sewage treatment device based on mechanical recompression technology:

[0036] This device comprises separator 6, evaporation heat exchanger 1, circulation pump 2, feed pump 12, vacuum pump 10, compressor 5 and condensation water pump 11; Described evaporation heat exchanger 1 bottom is connected with evaporation heat exchanger 1 The feed pipeline connected by the tube side, the feed pump 12 is arranged on the feed pipeline; the liquid circulation pipeline 3 is arranged between the evaporation heat exchanger 1 and the bottom of the separator 6, and the circulation pump 2 is arranged on the liquid circulation pipeline 3 Above; the compressor 5 is connected to the gas supply pipeline 8, the other end of the gas supply pipeline 8 is connected to the middle part of the evaporative heat exchanger 1, and the upper part of the evaporative heat exchanger 1 is connected to the liquid return pipeline 7 before the separator 6, The tu...

Embodiment 2

[0039] Embodiment 2, in the sewage treatment device based on mechanical recompression technology described in Embodiment 1: a condensation water tank 13 is also provided on the condensation pipeline 14 .

Embodiment 3

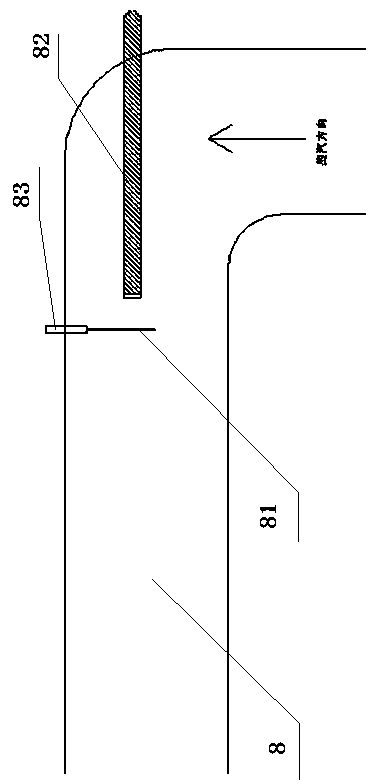

[0040] Embodiment 3, in a sewage treatment device based on mechanical recompression technology described in Embodiment 1 or 2: a negative pressure detection device is provided on the gas supply pipeline 8; the negative pressure detection mechanism is installed on the pipe elbow It is composed of a proximity switch 82, a blocking plate 81 and a fixing device 83; the proximity switch 82 is installed facing the steam direction, and the blocking plate 81 is fixedly installed on the side of the proximity switch 82 by the fixing device 83.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com