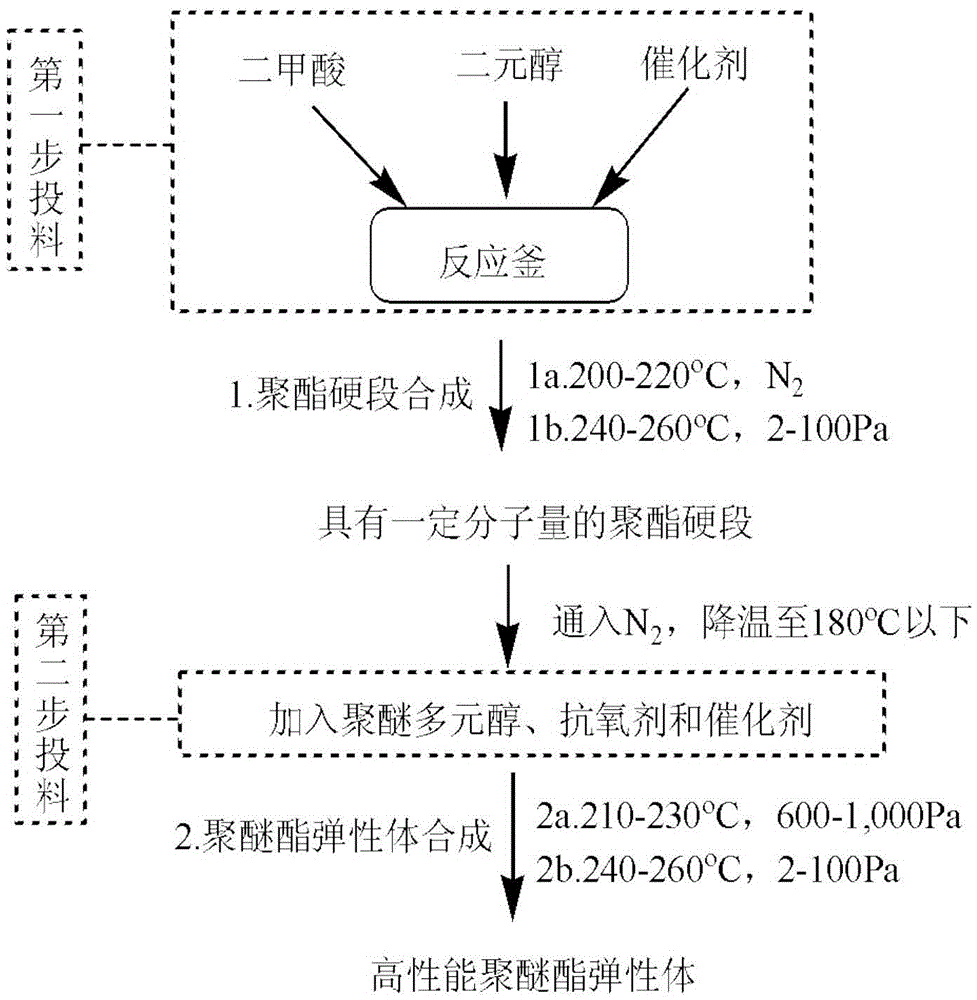

Two-step feeding synthesis method of high-performance polyetherester elastomer

A polyether ester elastomer, high-performance technology, applied in the field of two-step feeding synthesis method of high-performance polyether ester elastomer, can solve the problems of limited improvement of material mechanical properties, reduce production costs, and make the synthesis process easy to operate , Reduce the effect of thermal degradation side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Add 194.0g of terephthalic acid, 158.0g of butanediol and 0.097g of tetrabutyl titanate into a 1L reactor, react at 220°C for 4h under the protection of nitrogen, then raise the temperature to 240°C, and react for 1h under a vacuum of less than 60Pa . The temperature of the system was lowered to 180°C, nitrogen protection was introduced, and 367.0 g of polytetrahydrofuran (the average number of repeating units in the soft segment was 12.0) with a molecular weight of 1,000 g / mol, 0.097 g of tetrabutyl titanate and antioxidant 1010 were added. 0.485g. The system was slowly heated up to 230°C under the protection of nitrogen, then reacted under 1,000Pa vacuum for 1h, then raised the system temperature to 250°C, and reacted under less than 60Pa vacuum for 6h to obtain a polyether ester elastomer product. The samples were dried under water cooling and cutting into pellets. GPC test results show product molecular weight M n The PDI is 29,000g / mol, and the PDI ...

Embodiment 2

[0052] Example 2 Add 271.0g of terephthalic acid, 135.0g of butanediol and 0.1355g of isopropyl titanate into a 1L reactor, react at 220°C for 4h under the protection of nitrogen, then raise the temperature to 240°C, and react for 1h under a vacuum of less than 60Pa . The temperature of the system was lowered to 180°C, nitrogen protection was introduced, and 131.0 g of polytetrahydrofuran with a molecular weight of 1,000 g / mol (the average number of repeating units in the soft segment was 12.0), 0.1355 g of isopropyl titanate and 1098 antioxidant were added as 0.678g. The system was slowly heated up to 230°C under the protection of nitrogen, then reacted under 1,000Pa vacuum for 1h, then raised the system temperature to 250°C, and reacted under less than 60Pa vacuum for 6h to obtain a polyether ester elastomer product. The samples were cooled under water and pelletized and then vacuum-dried. GPC test shows product molecular weight M n 27,000g / mol, PDI 2.0; DSC test resul...

Embodiment 3

[0053] Example 3 Add 176.0g of terephthalic acid, 135.0g of butanediol and 0.088g of isopropyl titanate into a 1L reaction kettle, react at 220°C for 4h under the protection of nitrogen, then raise the temperature to 240°C, and react for 1h under a vacuum of less than 60Pa . The temperature of the system was lowered to 180°C, nitrogen protection was introduced, 87.0 g of polytetrahydrofuran (the average number of repeating units in the soft segment was 22.7), 0.088 g of isopropyl titanate and antioxidant 1010 were added. 0.44g. The system was slowly heated up to 230°C under the protection of nitrogen, and then reacted under a vacuum of about 1,000Pa for 1h, then the temperature of the system was raised to 250°C, and reacted under a vacuum of less than 60Pa for 6h to obtain a polyetherester elastomer product. The samples were cooled under water and pelletized and dried in vacuum. GPC test shows product molecular weight M n It is 28,000g / mol, and the PDI is 1.5; DSC result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com