Method for manufacturing vat brown RP dyestuffs

A dye and material technology, applied in the field of vat brown RP dye preparation, can solve the problems of poor quality and low cost, and achieve the effects of improving product yield, good product quality and improving dye performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

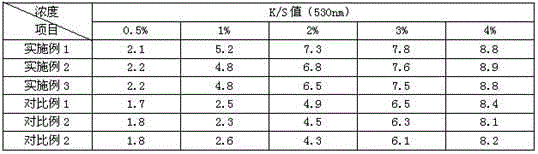

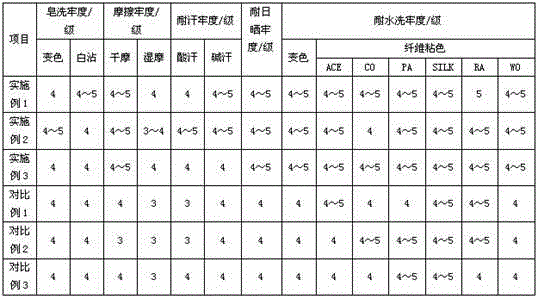

Examples

Embodiment 1

[0026] 1) Condensation reaction: mix 220kg of 3,9-dibromobenzoxanthrone, 210kg of 1-aminoanthraquinone, 110kg of soda ash and 6kg of copper oxide, heat up to 260°C for 5 hours, keep warm for 6 hours, cool down naturally for 0.5 hours, and then pulverize , and at the same time lower the temperature to the internal temperature of the material at 100°C, add the material to water with a mass ratio of 19 times, boil in water at 90-100°C for 1 hour, dilute and discharge the material, filter, and dry to obtain the condensate brown RP imine with a moisture content of ≤1 %,spare.

[0027] 2) Closed-loop reaction: Add 400kg of anhydrous aluminum trichloride to the reactor, start stirring, level the material, add 150kg of pyridine, then raise the temperature to 130°C, and keep it at 130-160°C for 6 hours. After the heat preservation, cool down to 100 ℃, add brown RP imine 60Kg, control the temperature during the feeding process at 90±10℃, then raise the temperature to 120℃, and keep it ...

Embodiment 2

[0030] 1) Condensation reaction: mix 220kg of 3,9-dibromobenzoxanthrone, 220kg of 1-aminoanthraquinone, 110kg of soda ash and 6kg of copper oxide, heat up to 265°C for 5 hours, keep warm for 6 hours, cool down naturally for 0.5 hours, and then pulverize , and at the same time lower the temperature to the internal temperature of the material at 100°C, add the material to water with a mass ratio of 19 times, boil in water at 90-100°C for 1 hour, dilute and discharge the material, filter, and dry to obtain the condensate brown RP imine with a moisture content of ≤1 %,spare.

[0031] 2) Closed-loop reaction: Add 400kg of anhydrous aluminum trichloride to the reactor, start stirring, level the material, add 150kg of pyridine, then raise the temperature to 150°C, and keep it at 140-160°C for 6 hours. After the heat preservation, cool down to 100 ℃, add 80Kg of brown RP imine, control the temperature at 90±10℃ during the feeding process, then raise the temperature to 120℃, and keep ...

Embodiment 3

[0034] 1) Condensation reaction: mix 220kg of 3,9-dibromobenzoxanthrone, 230kg of 1-aminoanthraquinone, 110kg of soda ash and 6kg of copper oxide, heat up to 265°C for 6 hours, keep warm for 6 hours, cool down naturally for 0.5 hours, and then pulverize , and at the same time lower the temperature to the internal temperature of the material at 100°C, add the material to water with a mass ratio of 19 times, boil in water at 90-100°C for 1 hour, dilute and discharge the material, filter, and dry to obtain the condensate brown RP imine with a moisture content of ≤1 %,spare.

[0035] 2) Closed-loop reaction: add 400kg of anhydrous aluminum trichloride to the reactor, start stirring, level the material, add 150kg of pyridine, then raise the temperature to 140°C, and keep it at 130-160°C for 6 hours. After the heat preservation, cool down to 100 ℃, add brown RP imine 50Kg, control the temperature during the feeding process at 90±10℃, then raise the temperature to 120℃, and keep it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com