Chitosanase and method for producing chitosan oligosaccharide by using same

A technology of chitosanase and glycanase, applied in the field of chitosanase and chitosan oligosaccharide production, can solve the problems of limited reaction conditions and low thermal stability, and achieve the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand a kind of chitosanase according to the scheme of the present invention and the method for using the polycanase to produce chitosan oligosaccharides, a preferred embodiment of the squid block grading device of the present invention will be further elaborated below.

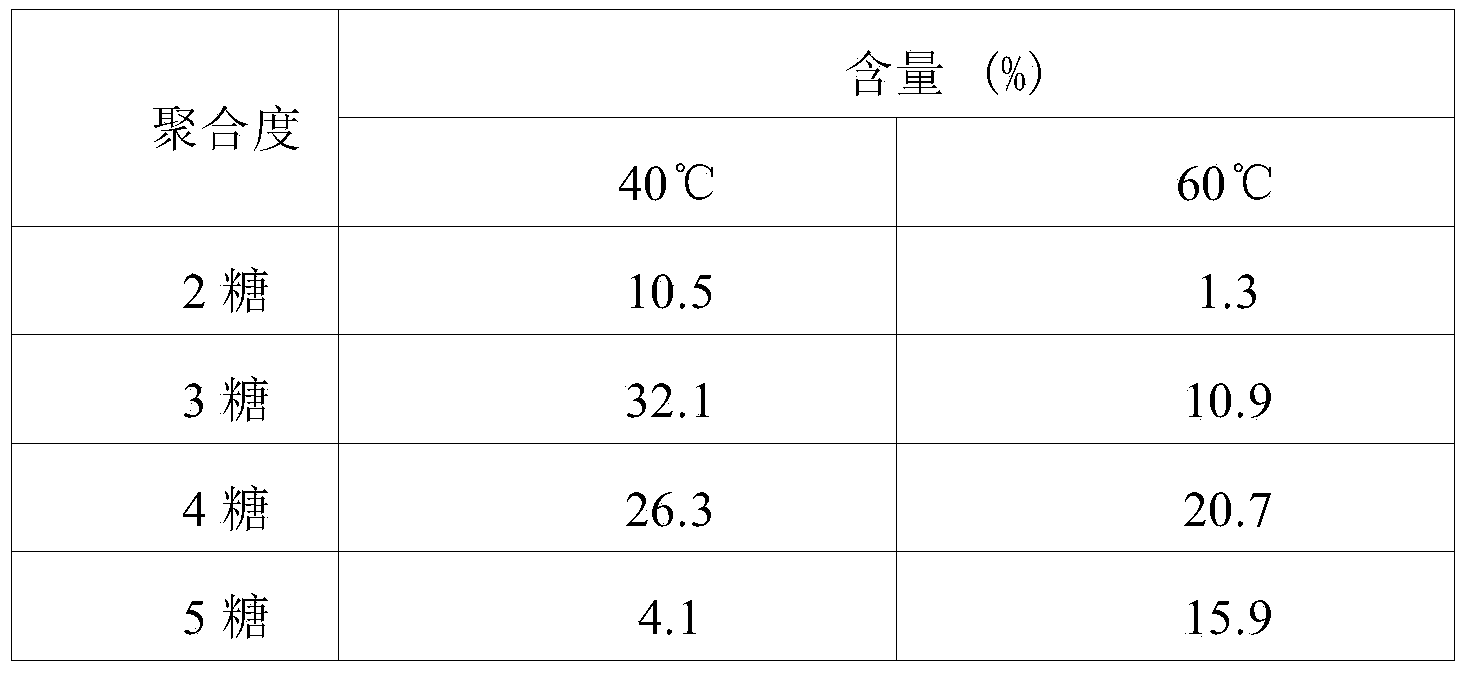

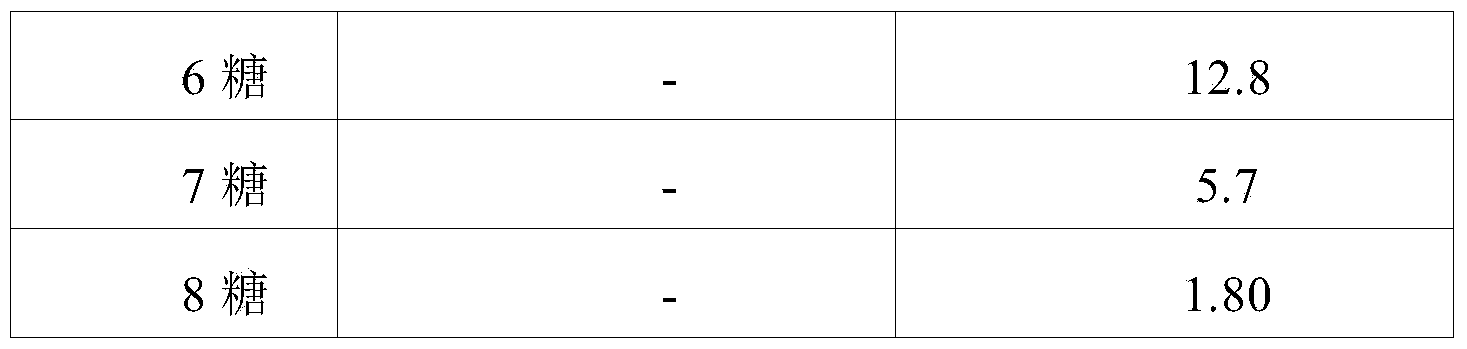

[0036] In order to produce chitosan oligosaccharides with a higher content of oligosaccharides of more than 6 sugars by enzymatic method, the inventors of the present invention have worked hard to find that there is a heat-resistant strain of Bacillus AMI09 isolated from the soil on the south coast of Gyeongnam, South Korea. High-performance chitosanase, utilizing the heat-resistant chitosanase to be able to produce chitosan oligosaccharides with high 6-saccharide content under high-temperature optimum reaction conditions, thereby completing the present invention. Thus, the object of the present invention is to provide a method for producing high-polymerization-degree chitosan ol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com