Preparation method of high-purity sulforaphen

A sulforaphane, high-purity technology, applied in fermentation and other directions, can solve the problems of unsuitability for industrial production, difficult regeneration of column chromatography materials, complicated production process, etc., and achieves the effects of high cost, long extraction time and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Weigh 1 kg of washed red radish, add 200 mL of water, and mash it with a tissue masher to obtain radish juice;

[0023] 2) Grind 100 g of dried broccoli seeds through a 60-mesh sieve, add 200 mL of radish juice prepared in step 1) and 0.1 g of V C Catalyzed enzymolysis at room temperature for 30 minutes to obtain a solid-liquid mixture;

[0024] 3) Add 2000mL of water to the solid-liquid mixture obtained in step 2), mix well, extract with 40MPa high-pressure homogeneous circulation, and collect the filtrate by filtration;

[0025] 4) Add 2000mL ionic liquid [BMIM][PF to the filtrate obtained in step 3) 6 ] extracted 3 times, combined the organic phase, added 2000mL absolute ethanol to the organic phase to back-extract the sulforaphane, and reclaimed the ionic liquid;

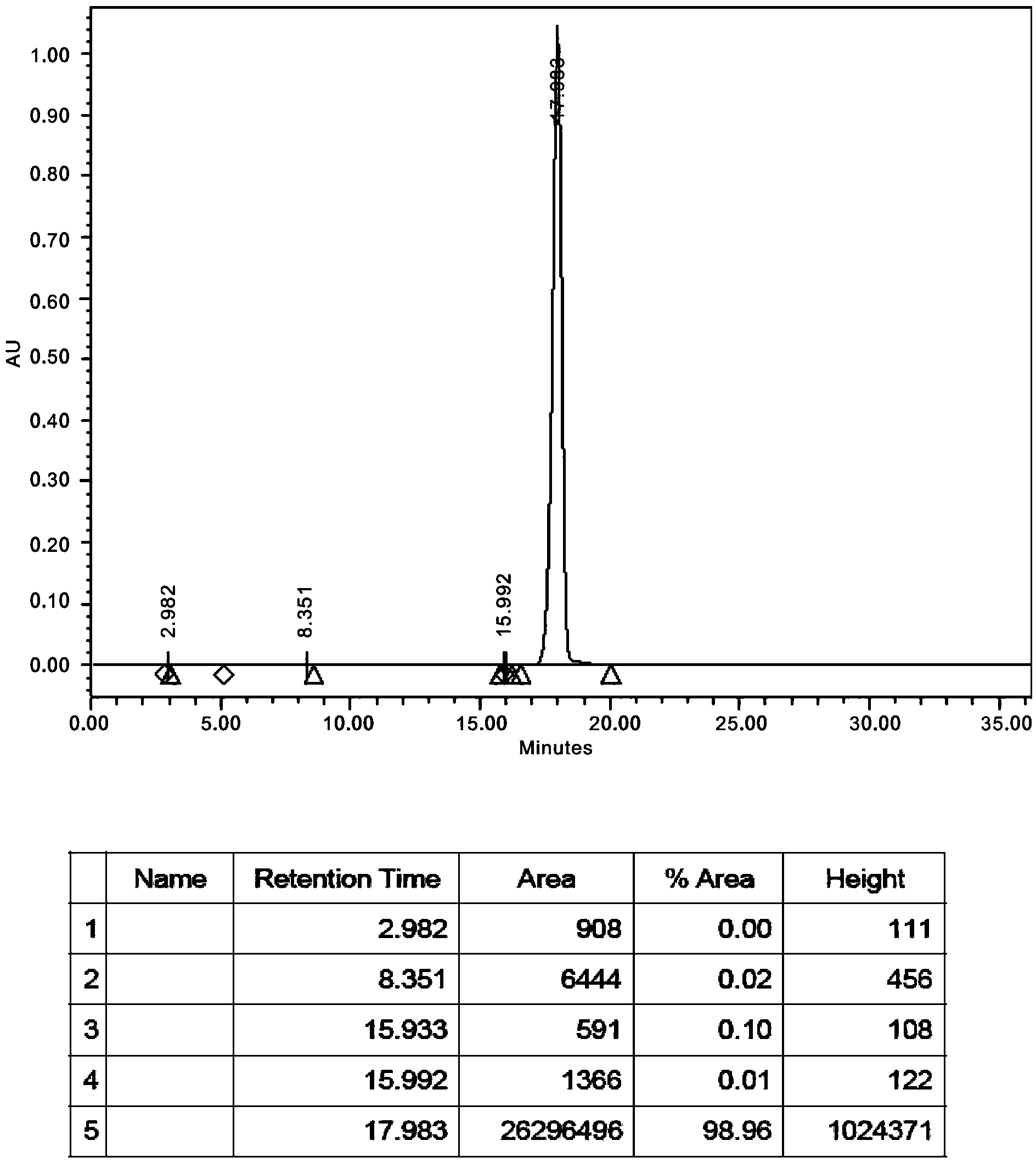

[0026] 5) Concentrating the mixture of sulforaphane and ethanol obtained in step 4) back-extracted in vacuo to an oily extract to obtain the sulforaphane extract. Weigh 5 mg of oily extract and add ...

Embodiment 2

[0028] 1) Weigh 1 kg of washed carrots, add 400 mL of water, and mash with a tissue masher to obtain radish juice;

[0029] 2) Grind 300g of dried broccoli seeds through a 60-mesh sieve, add 400mL of radish juice prepared in step 1) and 0.3g of V C Catalyzed enzymolysis at room temperature for 50 minutes to obtain a solid-liquid mixture;

[0030] 3) Add 4000mL of water to the solid-liquid mixture obtained in step 2), mix well, extract with 60MPa high-pressure homogeneous circulation, and collect the filtrate by filtration;

[0031] 4) Add 3000mL ionic liquid [BMIM][PF to the filtrate obtained in step 3) 6 ] extracted 3 times, combined the organic phase, added 3000mL absolute ethanol to the organic phase to back-extract the sulforaphane, and reclaimed the ionic liquid;

[0032] 5) Concentrating the mixture of sulforaphane and ethanol obtained in step 4) back-extracted in vacuo to an oily extract to obtain the sulforaphane extract. Weigh 5 mg of oily extract and add 10 mL of ...

Embodiment 3

[0034] 1) Weigh 1 kg of washed white radish, add 300 mL of water, and mash it with a tissue masher to obtain radish juice;

[0035] 2) Grind 200 g of dried broccoli seeds through a 60-mesh sieve, add 300 mL of radish juice prepared in step 1) and 0.2 g of V C Catalyzed enzymolysis at room temperature for 40 minutes to obtain a solid-liquid mixture;

[0036] 3) Add 3000mL of water to the solid-liquid mixture obtained in step 2), mix well, extract with 50MPa high-pressure homogeneous circulation, and collect the filtrate by filtration;

[0037] 4) Add 4000mL ionic liquid [BMIM][PF to the filtrate obtained in step 3)6 ] extracted 3 times, combined the organic phase, added 3000mL absolute ethanol to the organic phase to back-extract the sulforaphane, and reclaimed the ionic liquid;

[0038] 5) Concentrating the mixture of sulforaphane and ethanol obtained in step 4) back-extracted in vacuo to an oily extract to obtain the sulforaphane extract. Weigh 5 mg of oily extract and add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com