A kind of preparation method of high crystallinity boron nitride

A high-crystallinity, boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high template agent cost, high calcination temperature, long production cycle, etc., to save energy consumption, reduce Effect of crystallization temperature and diffraction peak intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Dissolve 0.04mol of sodium borohydride and 0.04mol of ammonium fluoroborate in 20mL of dioxane, respectively, and then add them to the flask in turn, stir electromagnetically at 45°C for 1h, let stand and cool to room temperature, and filter with suction to obtain ammonia boron Alkanes clarification solution, stand-by;

[0021] (2) 0.20 gram of PVB is dissolved in 20mL of dioxane solution, makes clear solution of PVB, stand-by;

[0022] (3) Pour all the clear solutions prepared in step (1) and step (2) into the autoclave successively to obtain the ammonia borane-PVB mixed solution, heat it in solvent at 160°C for 4h, let it stand and cool to room temperature, 80 °C, the solvent was distilled off under reduced pressure to obtain a white hybrid powder, which was set aside;

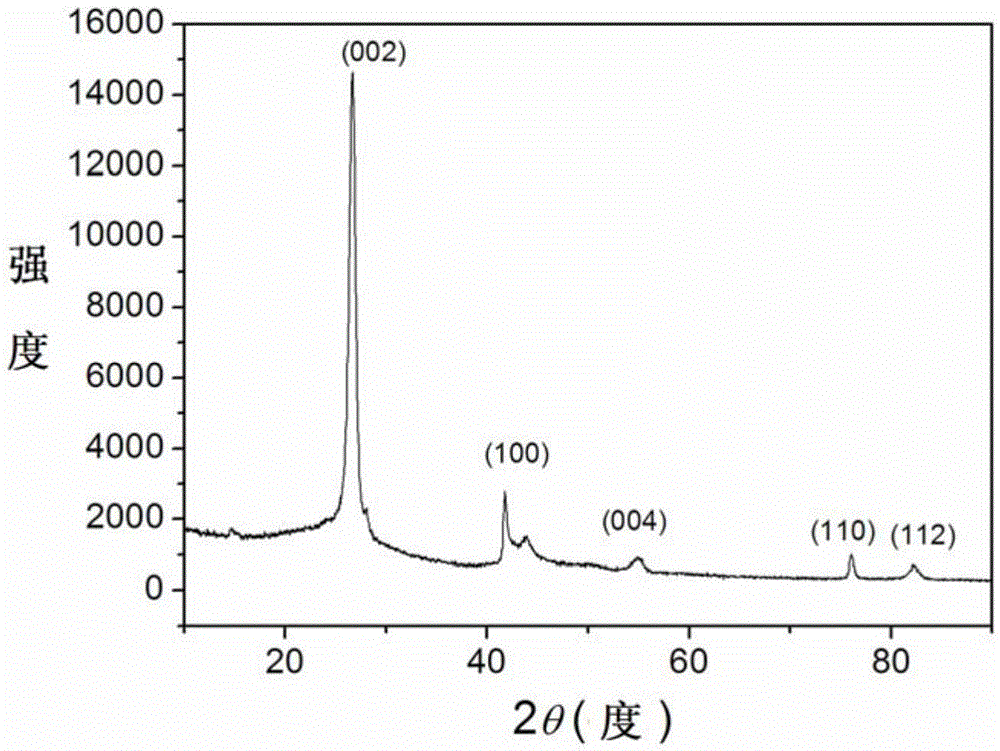

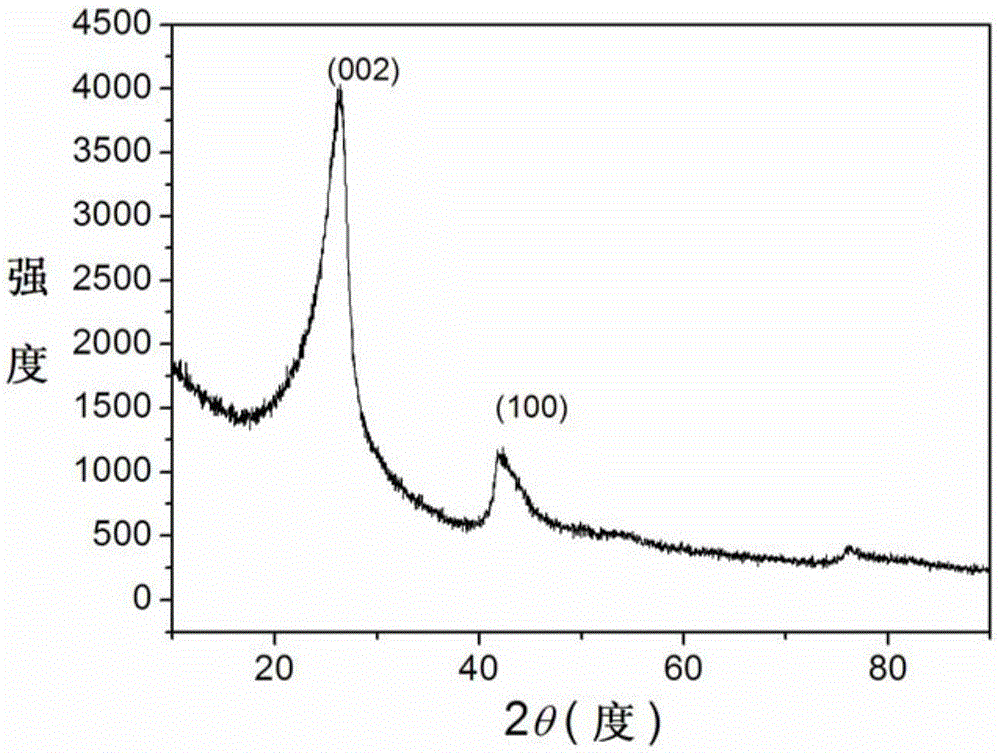

[0023] (4) Put the white powder obtained in step (3) in a tube furnace, calcined at 1000°C in an ammonia atmosphere, keep it warm for 5h, and then calcined at 700°C for 2h in an air atmosphere in...

Embodiment 2

[0025] The ammonium fluoroborate in the step (1) in the embodiment 1 is replaced by ammonium formate, and other steps are the same as in the embodiment 1. The obtained product is boron nitride powder with high crystallinity.

Embodiment 3

[0027] The PVB (polyvinyl butyral) consumption in step (2) in embodiment 1 is reduced to 0.02g, and other steps are with embodiment 1. The obtained product is boron nitride powder with high crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com