Sewage treatment process for dispelling sludge in situ through biological regulation and control

A technology for sewage treatment and biological sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor dephosphorization effect and achieve good sewage treatment Effectiveness, elimination of sludge discharge, and small footprint of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

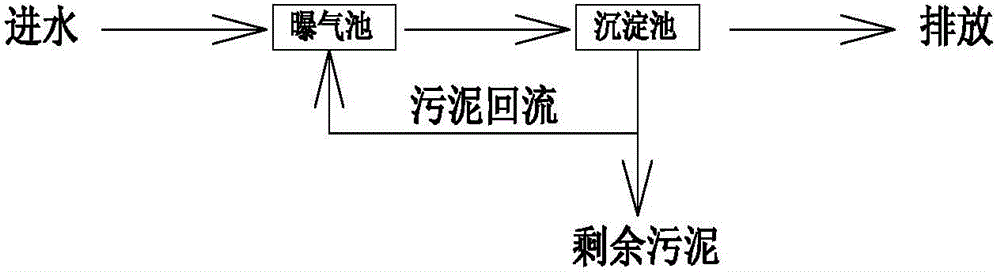

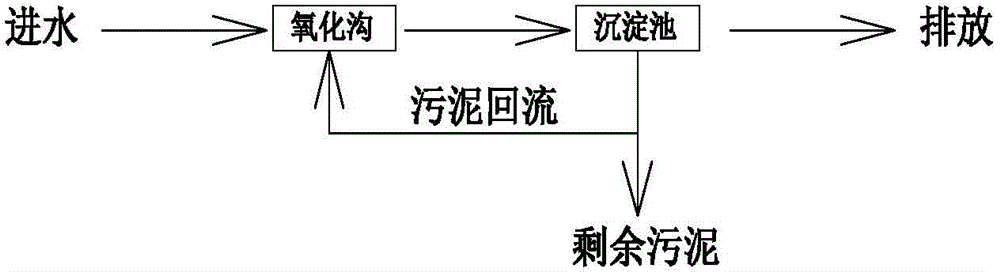

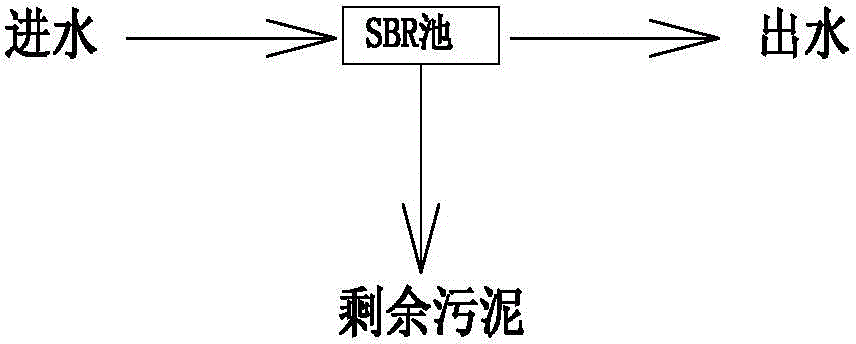

Image

Examples

Embodiment

[0028] Example: such as Figure 7 As shown, the sewage treatment process of biologically regulated in-situ digestion of sludge is as follows:

[0029] Step 1. The remaining sludge in the sedimentation tank in the sewage biological treatment process is treated with ozone micro-nano bubbles to obtain a mixed solution of broken cell decomposition, which is homogeneously mixed with raw sewage and used as sewage influent, which enters anaerobic anoxic and then enters aerobic biochemical pool. In the operation steps, the sludge concentration of the mixed liquor is controlled to be 20000-30000mg / L. The dehydration treatment time of micro-nano ozone bubble wall broken cells is 0.5-2 hours, and the dissolved oxygen concentration of the mixed solution is controlled at 3-4mg / L;

[0030] Step 2: Part of the mixed solution of the broken cell decomposition mixed solution obtained after treatment with ozone micro-nano bubbles is selected and cultivated by the light of life to obtain a mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com