Sulfate-resistant and corrosion-resistant impervious non-autoclaved C80P12 concrete pipe pile

A C80P12, concrete pipe pile technology, applied in the field of concrete, can solve the problems of the decline of the corrosion resistance and impermeability of the surface of the pipe pile, the influence of the anti-splitting performance of the pipe pile concrete, and the reduction of the driving resistance and durability of the pipe pile body. Improve overall quality performance, good protection, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

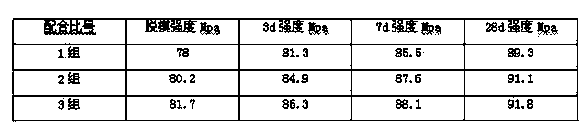

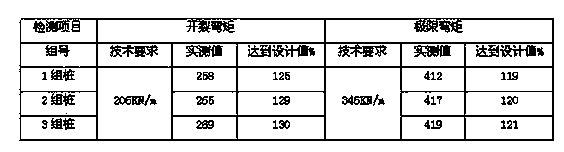

[0019] According to the design mix ratio 1, 2, and 3 group numbers, test and trial production are carried out, and three PHC600 (AB) 110-13m pipe piles are trial-manufactured. See the attached table for the mix ratio and strength of the test mix ratio. The concrete samples of the trial-manufactured pipe piles are sampled from the distribution port. The test block shall be cured under the same conditions as the trial-manufactured pipe pile according to the maintenance process system. The raw material quality of the trial-manufactured pipe pile and the technical requirements related to the production process are shown in the following attached table:

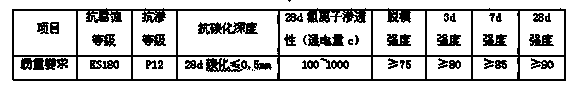

[0020] Sulfate-resistant corrosion-resistant seepage-free autoclaved C80 P12 concrete quality design requirements indicators, Table 1

[0021]

[0022] Design mix ratio 1 cubic meter material unit consumption, Table 2

[0023]

[0024] 42.5P.HSR High Sulfate Resistant Portland Cement Test Quality Results, Table 3

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com