Soilless culture substrate for leaf vegetables

A technology of soilless culture substrate and leafy vegetables, applied in the directions of inorganic fertilizers, fertilizer mixtures, potash fertilizers, etc., to achieve the effects of reducing environmental pollution, lowering pH, and fewer uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

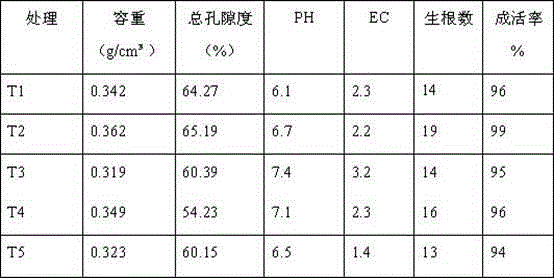

Examples

Embodiment 1

[0024] A soilless culture substrate for leafy vegetables, the main raw material of the substrate is a fermented mixture of organic wastes such as vinegar residue, cassava residue, and the volume ratio of vinegar residue and cassava residue is 1:1.

[0025] The raw materials are fermented and decomposed with a self-made high-temperature quick-rot agent for organic materials composed of actinomycetes, yeast, lactic acid bacteria, and bacillus. The bacteria content of the quick-rot agent is 150 million units / g, of which actinomycetes account for 60% The amount of fast rot agent is 15kg of fast rot agent per 100m3 of raw materials, and the fermentation time is about 55 days. The fermented organic mixture is dried and crushed and then added with vermiculite, plant ash and other auxiliary materials. Mixture 60%, vermiculite 20%, plant ash 20%.

[0026] Fully stir the fermented, decomposed, dried, crushed and processed organic mixture and auxiliary materials in proportion to form a f...

Embodiment 2

[0028] A soilless cultivation substrate for leafy vegetables comprises organic mixture, vermiculite and plant ash.

[0029] The organic mixture is a mixture of organic waste such as vinegar dregs and cassava residues that has been fermented and decomposed, and the volume ratio of vinegar residues and cassava residues is 1:2.

[0030] The volume ratio of the soilless cultivation matrix formula is: organic mixture 55%, vermiculite 20%, plant ash 25%.

[0031] The organic mixture is the decomposed material of vinegar residue and cassava residue mixture through fermentation treatment; the fermentation treatment is to use a high-temperature quick-rot agent to stack and decompose the vinegar residue and cassava residue; the consumption of the high-temperature quick-rot agent is Add 13.5kg of quick-rot agent per 100m3 of raw materials; the fermentation treatment composting time is 70 days.

[0032] The moisture content of the matrix is ≤50%, the organic matter content (dry basis) ...

Embodiment 3

[0034] The invention relates to a soilless cultivation substrate of leaf vegetables, which includes organic mixture, vermiculite and plant ash.

[0035] The organic mixture is a mixture of organic waste such as vinegar dregs and cassava residues that has been fermented and decomposed, and the volume ratio of vinegar residues and cassava residues is 1:3.

[0036] The volume ratio of the soilless cultivation substrate formula is: organic mixture 75%, vermiculite 10%, plant ash 15%.

[0037] The organic mixture is the decomposed material of vinegar residue and cassava residue mixture through fermentation treatment; the fermentation treatment is to use a high-temperature quick-rot agent to stack and decompose the vinegar residue and cassava residue; the consumption of the high-temperature quick-rot agent is Add 20kg of quick-rot agent per 100m3 of raw materials; the fermentation treatment composting time is 40 days.

[0038] The water content of the matrix is ≤50%, the organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com