A kind of superabsorbent resin and preparation method thereof

A super absorbent resin, adsorption process technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as waste of resources, achieve good adsorption, remove or reduce residues, and reduce water pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

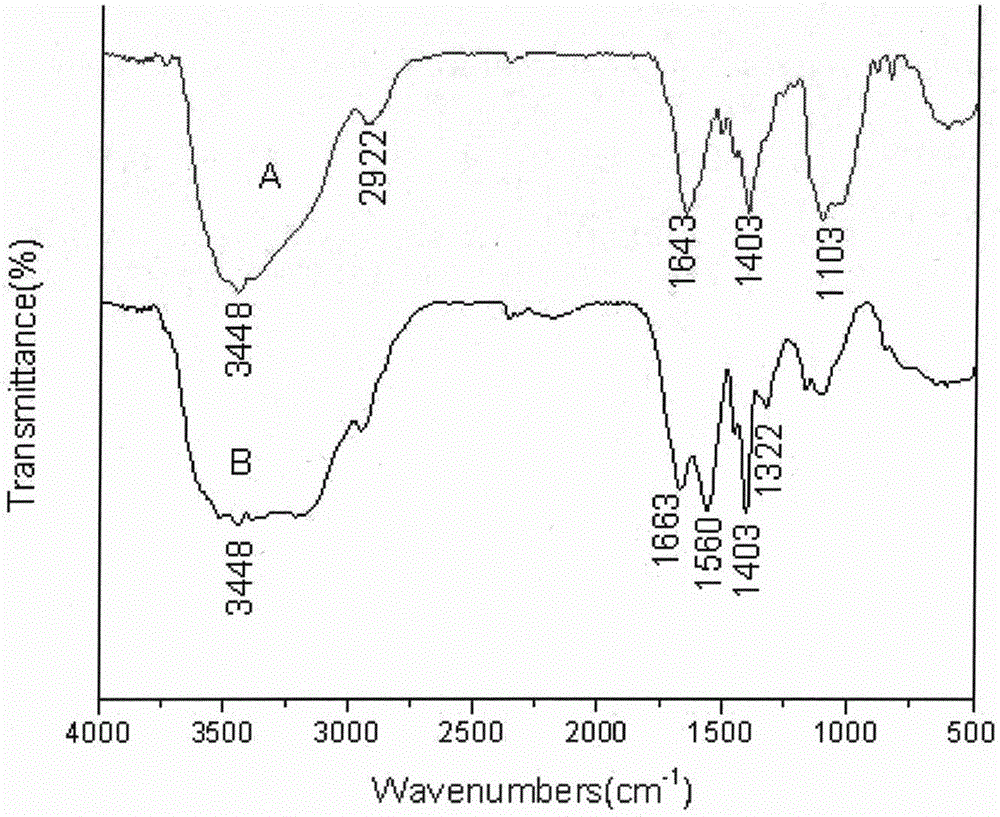

[0039] Example 1 Preparation of superabsorbent resin of the present invention

[0040] Seabuckthorn branches were washed and dried at 105°C for 12 hours. After the dried seabuckthorn branches are crushed, pass through a 110-mesh sieve, add 2% sodium hydroxide solution at a mass ratio of 1:12, put the mixture in a water bath at 100°C, centrifuge after 2 hours, and pour off the supernatant , wash the filtrate three times repeatedly with absolute ethanol, and finally dry the filtrate at 105°C for later use.

[0041] Weigh 9g of acrylic acid into a three-necked flask, and use N a OH aqueous solution (6M) for neutralization, then 3g of acrylamide, 0.12g of ammonium persulfate, 0.03g of N,N-methylenebisacryloyl, 2.4g of pretreated seabuckthorn branches and 5.0mL of distilled water were sequentially added to the above in solution. Finally, put the flask equipped with an electric stirrer, a thermometer and a nitrogen gas introduction tube into a water bath, and slowly heat to 70°C ...

Embodiment 2

[0042] Example 2 Preparation of super absorbent resin of the present invention

[0043] Seabuckthorn branches were washed and dried at 105°C for 12 hours. After the dried seabuckthorn branches are crushed, pass through a 110-mesh sieve, add 10% sodium hydroxide solution at a mass ratio of 1:10, put the mixture in a water bath at 100°C, centrifuge after 2 hours, and pour off the supernatant , wash the filtrate three times repeatedly with absolute ethanol, and finally dry the filtrate at 105°C for later use.

[0044] Weigh 9g of acrylic acid into a three-necked flask, and use N a OH aqueous solution (6M) for neutralization, then 3g of acrylamide, 0.12g of ammonium persulfate, 0.03g of N,N-methylenebisacryloyl, 2.4g of pretreated seabuckthorn branches and 5.0mL of distilled water were sequentially added to the above in solution. Finally, put the flask equipped with an electric stirrer, a thermometer and a nitrogen gas introduction tube into a water bath, and slowly heat to 70°...

Embodiment 3

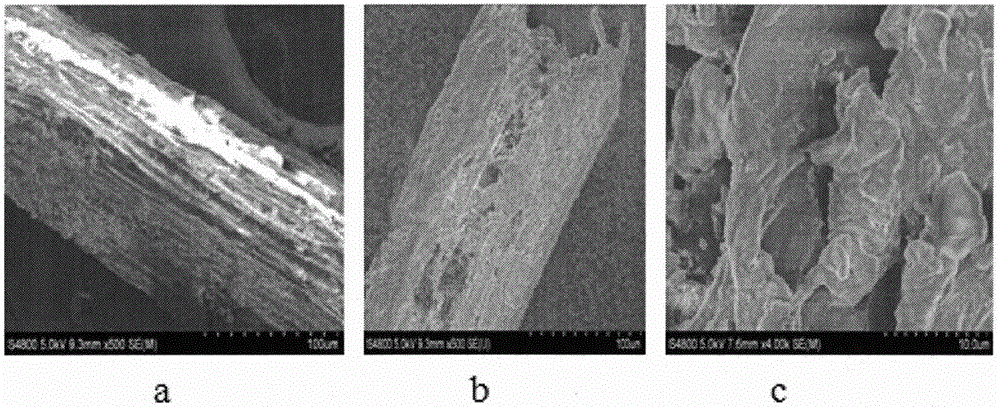

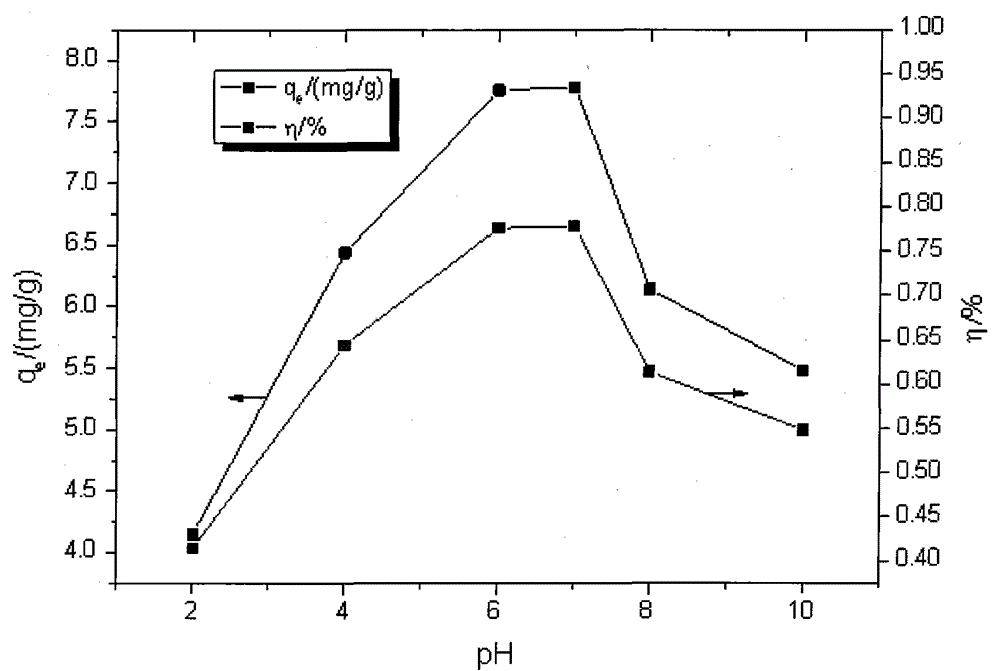

[0045] Example 3 Investigation of the superabsorbent resin of the present invention

[0046] ■1 Experimental part

[0047] ■1.1 Experimental Instruments

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com