Nano phase change and energy storage luminescent fibers and preparation method thereof

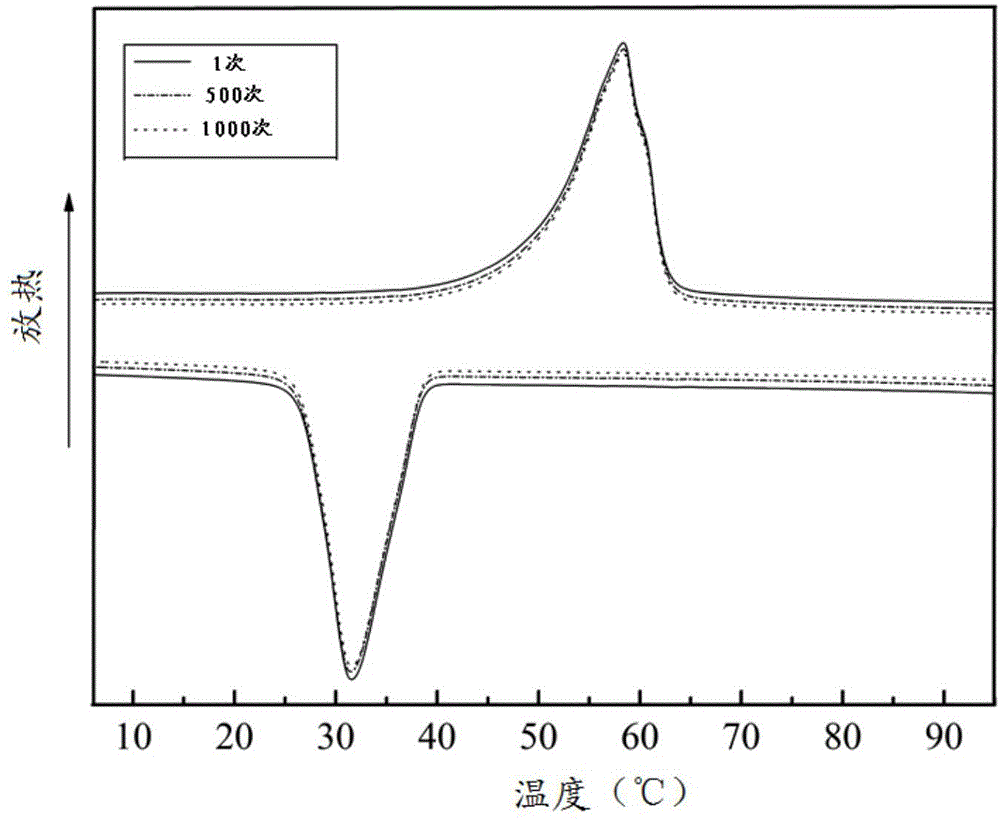

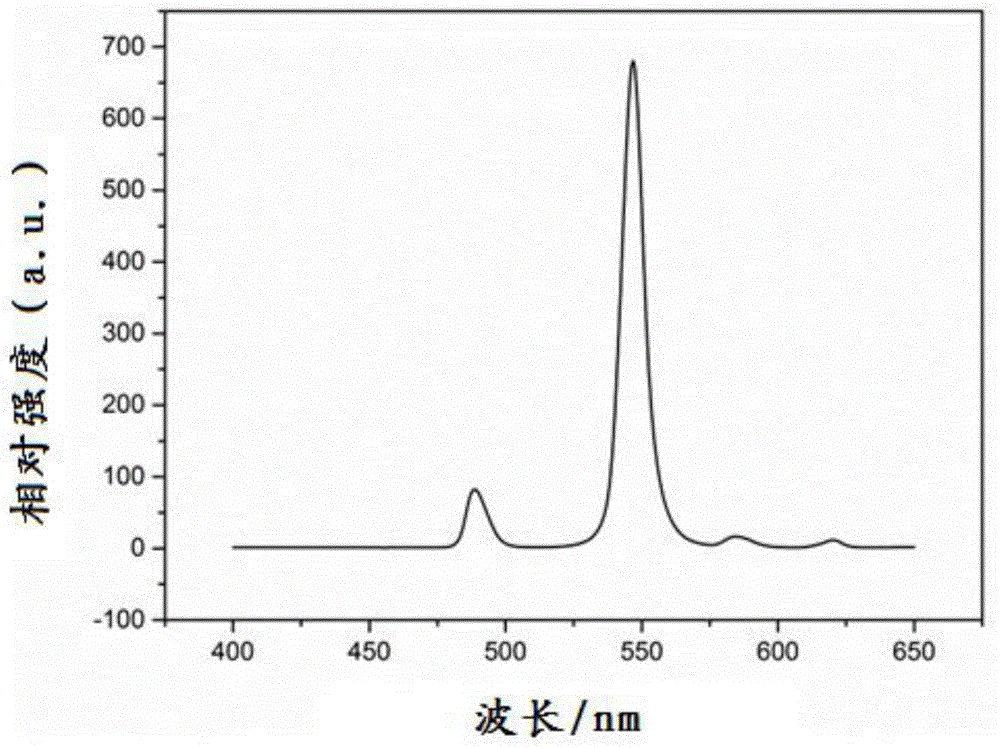

A technology of luminescent fiber and nanophase, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of decreased fluorescence intensity, difficulty in uniform dispersion, and low addition amount, so as to increase the phase transition rate and improve the color Effect of purity and fluorescence lifetime, excellent photoluminescent function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a nano phase change energy storage luminescent fiber, specifically implemented according to the following steps:

[0047] Step 1, weigh 1 gram of polyurethane solid-solid phase change material, 0.105 gram of Eu (p-methoxybenzoic acid) 3 (1,10-phen);

[0048] Step 2, weigh 1.75 grams of ethyl acetate and 3.5 grams of N,N-dimethylformamide to make a mixed solvent, dissolve the weighed polyurethane solid-solid phase change material in ethyl acetate and N,N-dimethylformamide A transparent solution was prepared in a complex solvent of methyl formamide, and the configuration condition was magnetic stirring at 65°C for 2 hours;

[0049] Step 3, weighing 0.18375 grams of ethyl acetate and 0.3675 grams of N, N-dimethylformamide to make a mixed solvent, the weighed Eu (p-methoxybenzoic acid) 3 (1,10-phen) was dissolved in a composite solvent of ethyl acetate and N,N-dimethylformamide to prepare a transparent solution, and the preparation condition was ma...

Embodiment 2

[0052] A preparation method of a nano phase change energy storage luminescent fiber, specifically implemented according to the following steps:

[0053] Step 1, weigh 0.5 gram of polymethyl methacrylate (PMMA), 0.5 gram of polyurethane solid-solid phase change material and 0.112 gram of Tb (p-methoxybenzoic acid) 3 (1,10-phen);

[0054] Step 2, weighing 0.875 gram ethyl acetate and 1.75 gram N, N-dimethylformamide make mixed solvent; Polymethyl methacrylate (PMMA) that weighs is dissolved in ethyl acetate and N, N- A transparent solution was prepared in a complex solvent of dimethylformamide, and the preparation condition was magnetic stirring for 2 hours at 65°C;

[0055] Step 3, weigh 0.875 grams of ethyl acetate and 1.75 grams of N, N-dimethylformamide to make a mixed solvent; dissolve the weighed polyurethane solid-solid phase change material in ethyl acetate and N, N-dimethylformamide A transparent solution was prepared in a composite solvent of methylformamide, and the...

Embodiment 3

[0059] A preparation method of a nano phase change energy storage luminescent fiber, specifically implemented according to the following steps:

[0060] Step 1, weigh 0.5 gram of polymethyl methacrylate (PMMA), 0.5 gram of polyurethane solid-solid phase change material, 0.122 gram of Tb (p-methoxybenzoic acid) 3 (1,10-phen);

[0061] Step 2, weighing 0.875 gram ethyl acetate and 1.75 gram N, N-dimethylformamide make mixed solvent; Polymethyl methacrylate (PMMA) that weighs is dissolved in ethyl acetate and N, N- A transparent solution was prepared in a complex solvent of dimethylformamide, and the preparation condition was magnetic stirring for 2 hours at 65°C;

[0062] Step 3, weigh 0.875 grams of ethyl acetate and 1.75 grams of N, N-dimethylformamide to make a mixed solvent; dissolve the weighed polyurethane solid-solid phase change material in ethyl acetate and N, N-dimethylformamide A transparent solution was prepared in a composite solvent of methylformamide, and the pr...

PUM

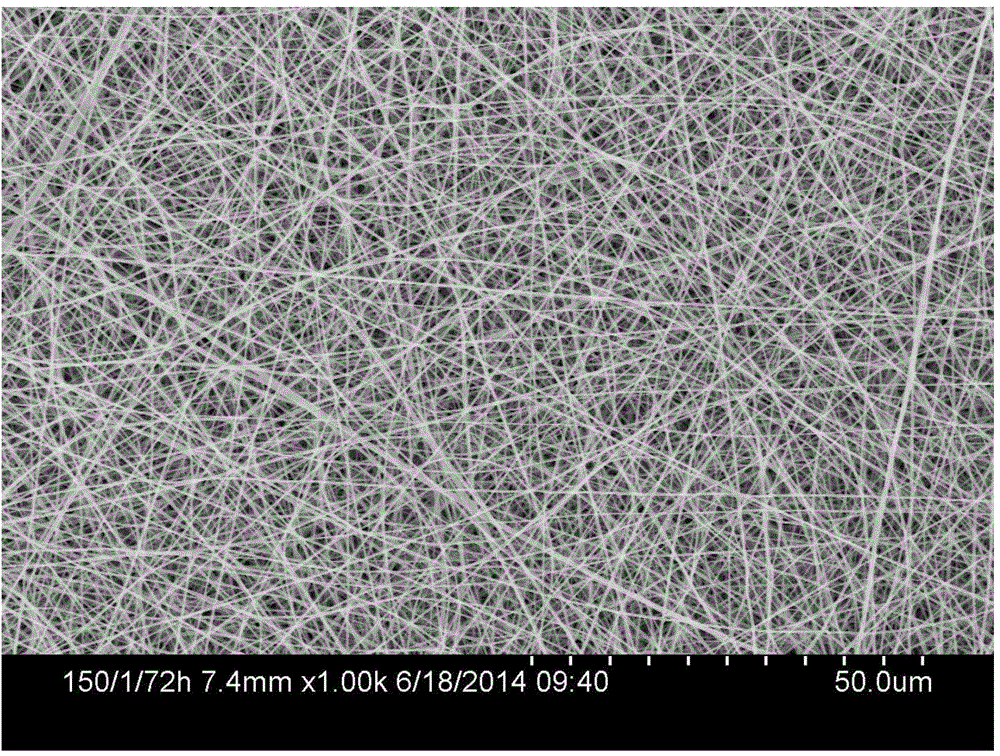

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com