All-optical fluid mass-flow monitoring device and method

A fluid quality and flow monitoring technology, which is applied in the direction of mass flow measurement devices, application of thermal effects to detect fluid flow, etc., can solve the problems that mass flow meters cannot be used, potential safety hazards of electric sparks, and easy corrosion of heating wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

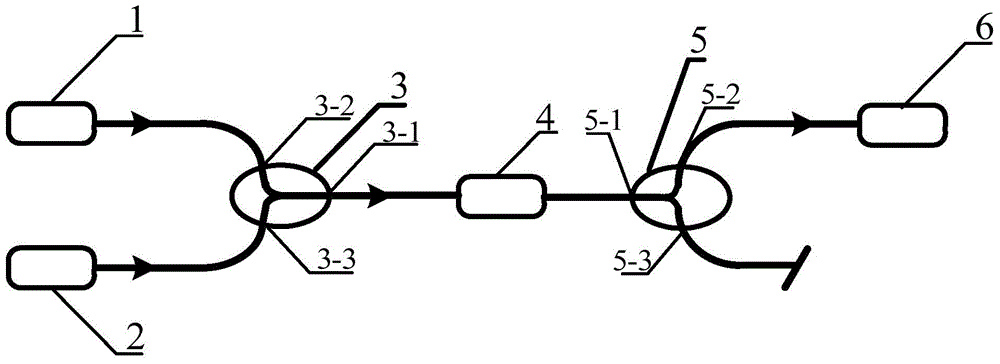

[0026] like figure 1 As shown, this embodiment is an all-optical fluid mass flow monitoring device, including a heating light source 1, a detection light source 2, a first filtering wavelength division multiplexer 3, a sensing unit 4, and a second filtering wavelength division multiplexer. Apparatus 5 and spectral analysis equipment 6. The heating light source 1, the detection light source 2, and the sensing unit 4 are all connected to the first filtering wavelength division multiplexer 3, respectively, and the second filtering wavelength division multiplexer 5 is respectively connected to the other end of the sensing unit 4 and the spectral analysis equipment. 6.

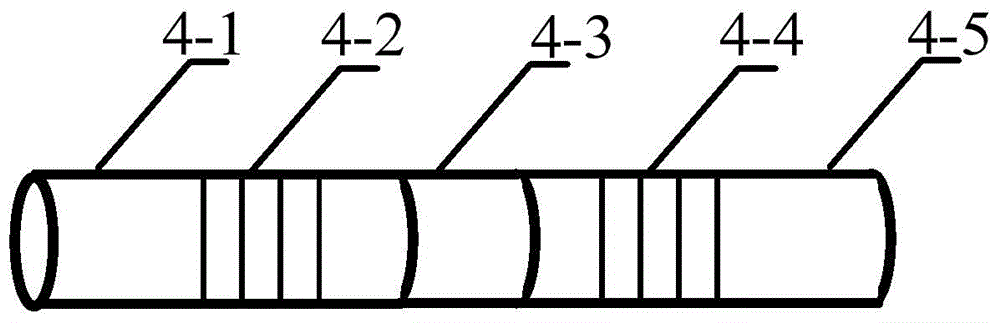

[0027] The structure of the sensing unit in this embodiment is as follows figure 2 As shown, the sensing unit 4 is a composite structure of a single-mode optical fiber (4-1), a photothermal optical fiber (4-3), and a single-mode optical fiber (4-5), which are spliced by a fusion splicer. Fiber Bragg gratings ...

Embodiment 2

[0035] Other structures of this embodiment are the same as those of Embodiment 1 except the following features:

[0036] In this embodiment, for high-risk gases such as gas, carbon monoxide and acetylene, or corrosive gases such as chlorine and hydrogen chloride, the length of the fiber Bragg gratings 4-2 and 4-4 is selected as 2mm, and the length of the photothermal fiber 4-3 is selected as 1mm.

Embodiment 3

[0038] Other structures of this embodiment are the same as those of Embodiment 1 except the following features:

[0039] In this embodiment, for flammable and explosive liquids such as ethanol and isoacetone, the length of the fiber Bragg gratings 4-2 and 4-4 is selected as 2 mm, and the length of the photothermal fiber 4-3 is selected as 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com