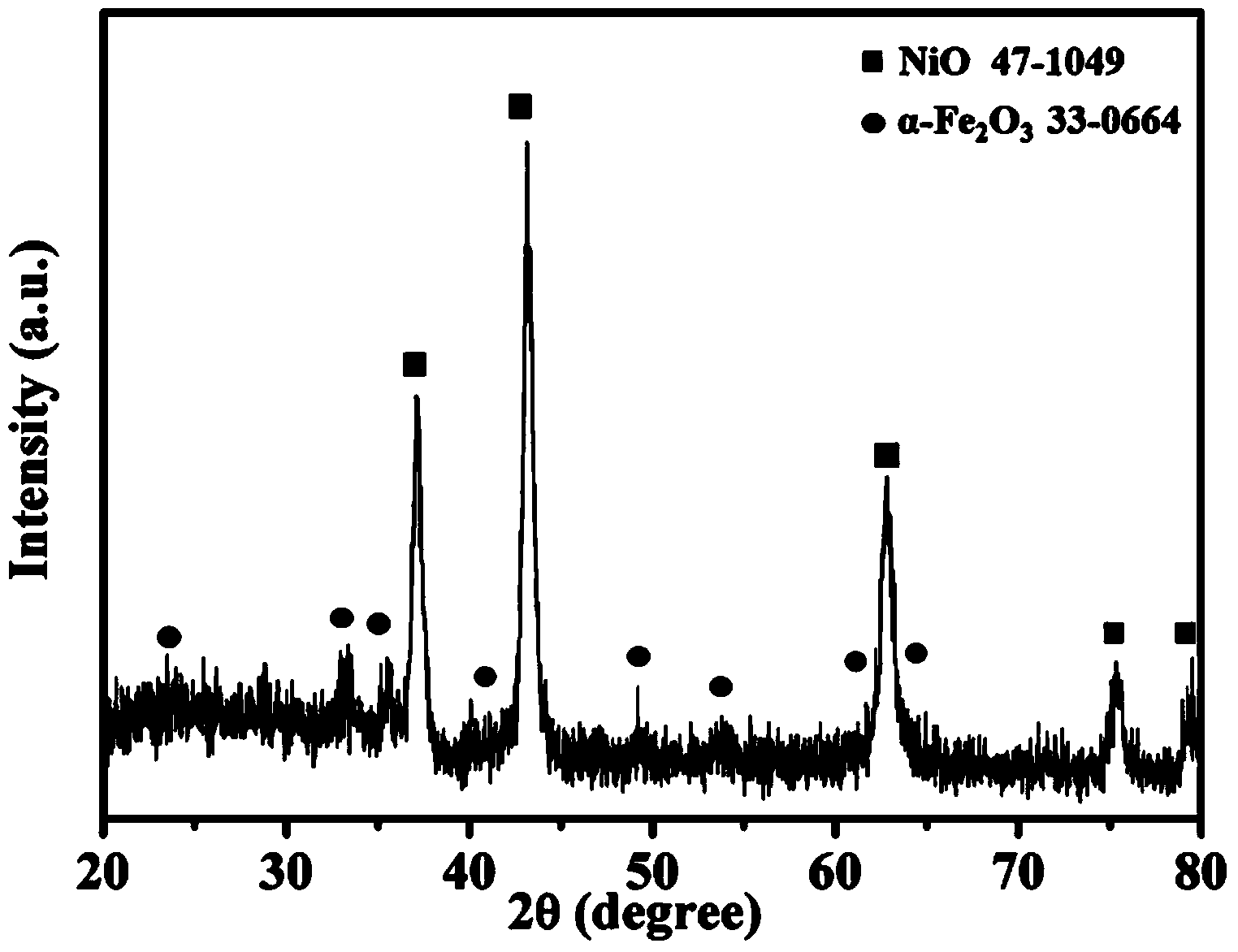

Toluene sensor based on alpha-Fe2O3/NiO heterostructure nanotube and preparation method of toluene sensor

A heterostructure, -fe2o3 technology, applied in the direction of material resistance, can solve the problems of limiting the application of NiO-based gas sensors, low sensitivity, etc., to achieve the effect of being suitable for mass production, improving sensitivity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

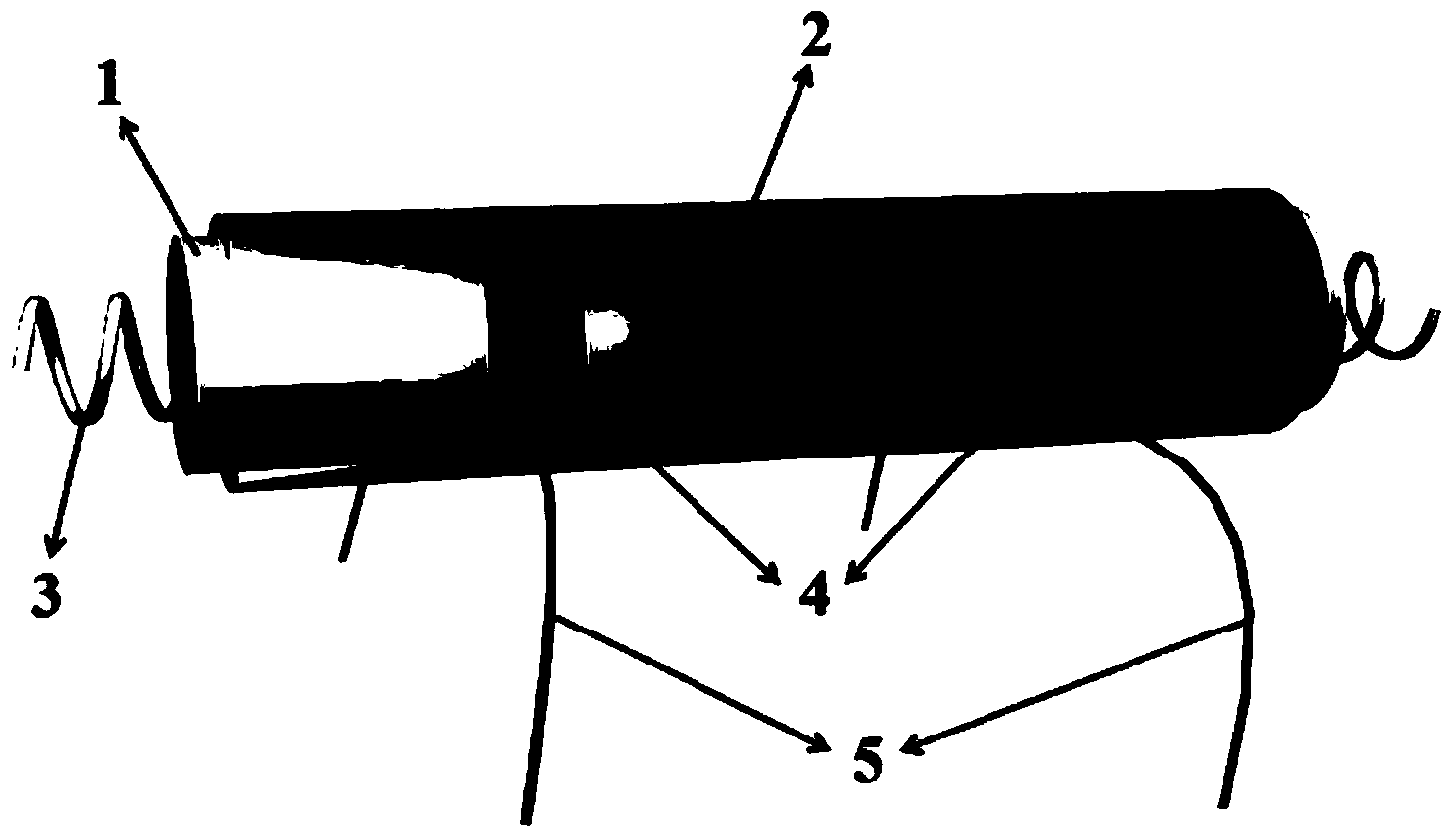

[0040] Using α-Fe2O3 / NiO heterostructure nanotubes as sensitive materials to make toluene sensors, the specific manufacturing process:

[0041] 1. First, add 0.4754g of NiCl2 6H2O and 0.063g of oxalic acid into the mixed solution composed of 9mL of deionized water and 16mL of glycerin, and keep stirring until it is completely dissolved;

[0042] 2. Transfer the above solution to a reaction kettle with a volume of 40mL, and react at 150°C for 12 hours. After cooling to room temperature, wash the resulting precipitate with deionized water and ethanol for several times, and then dry it at room temperature before placing it in Calcined at 400°C for 1 hour to obtain NiO nanotube powder assembled from NiO nanoparticles;

[0043] 3. Take 10mg of the above-mentioned NiO nanotube powder and add it to 20mL deionized water, sonicate for 10 minutes to completely disperse the NiO nanotube powder in the deionized water, then add 8.6mg FeCl3·6H2O and 10.3mg Na2SO4·10H2O in sequence, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com