Manufacturing method of ultrathin printed circuit board, and ultrathin printed circuit board

A technology of printed circuit board and manufacturing method, applied in the directions of printed circuit manufacturing, printed circuit, printed circuit components, etc., to prevent deformation and avoid scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The method for making an ultra-thin printed circuit board is characterized in that it comprises the following steps:

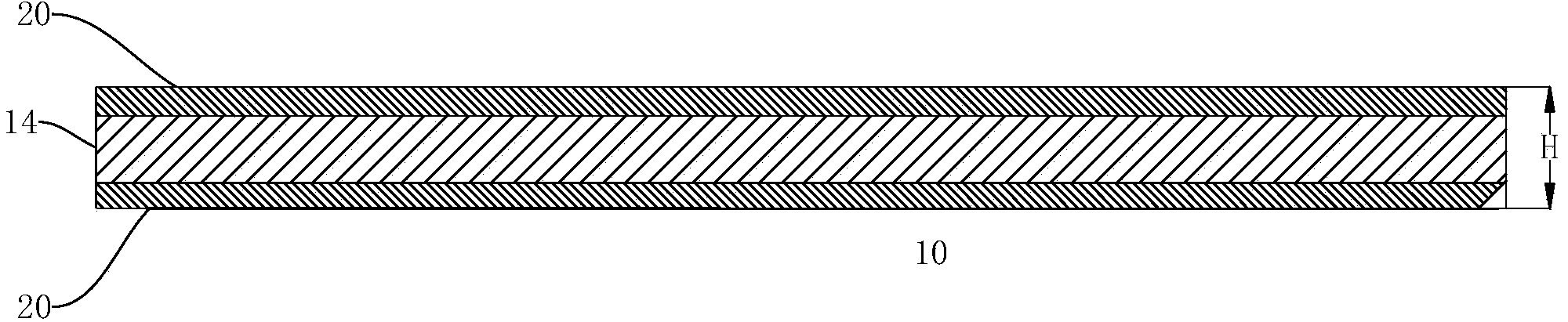

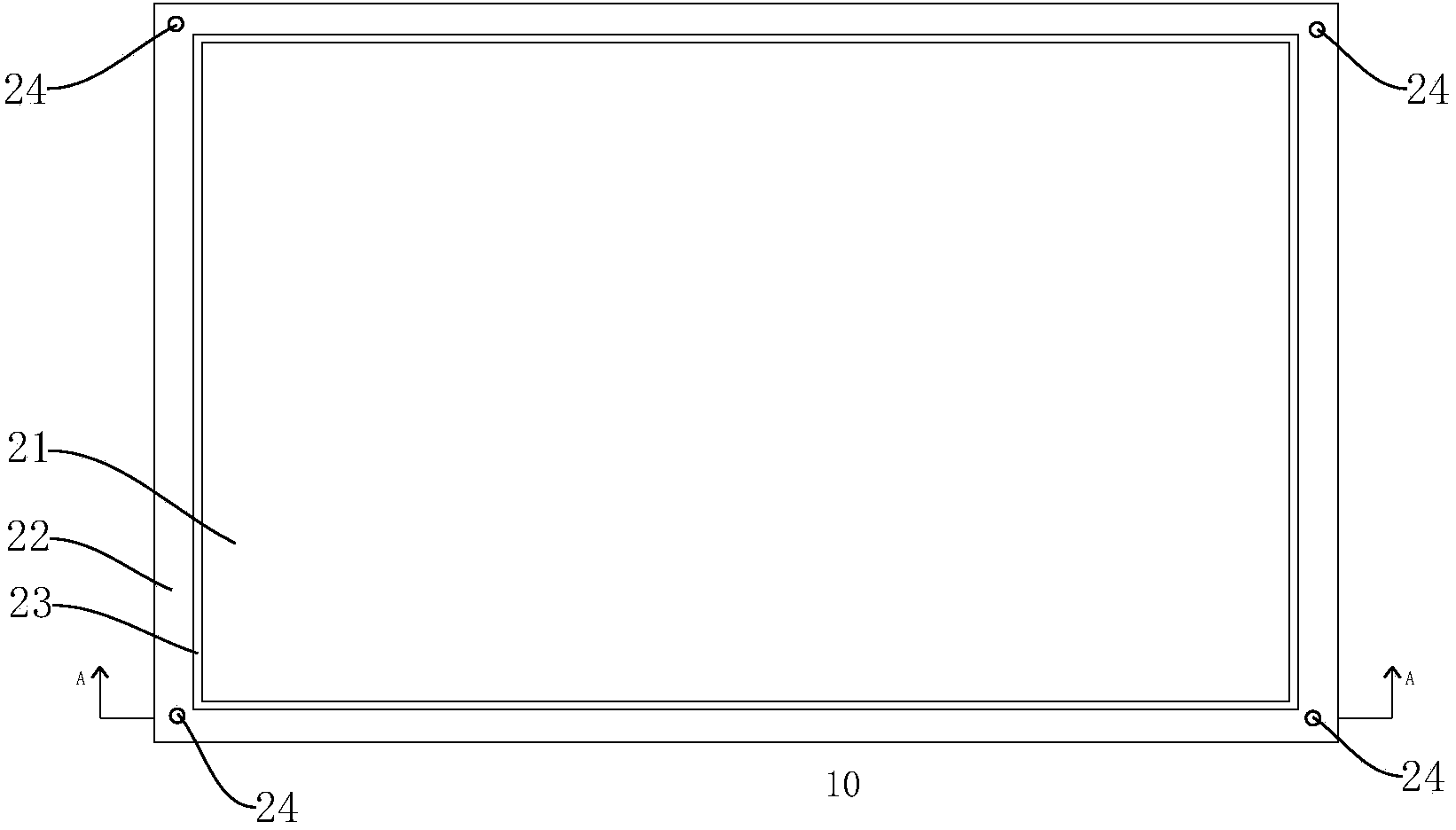

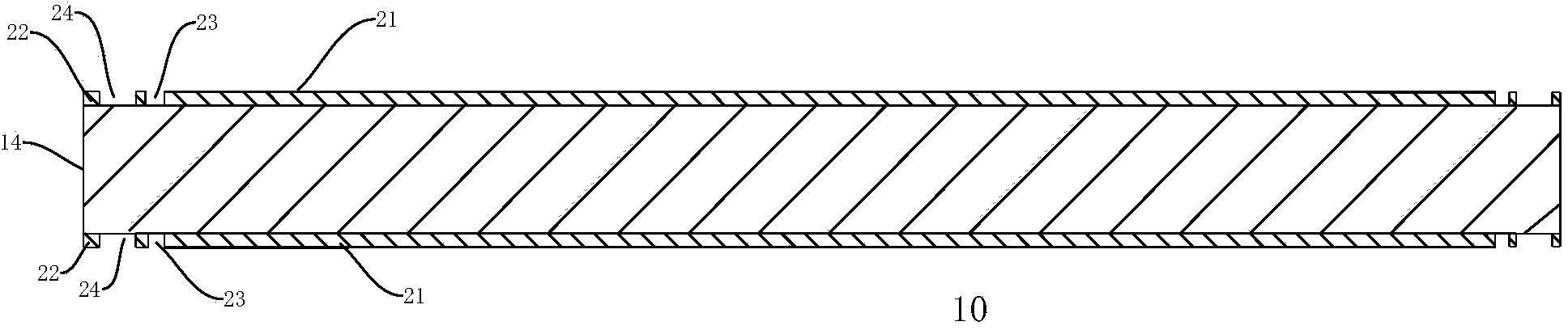

[0055] a. If figure 1 As shown, a polymer material core board 14 is provided, and a positioning copper foil 20 is respectively arranged on the upper surface and the lower surface, and the positioning copper foil 20 is bonded to the polymer material core board 14 . Such as figure 2 , image 3 As shown, pattern transfer, etching or milling is performed on the positioning copper foil 20 to form a through groove 23 so that the positioning copper foil 20 forms a positioning template 21 and a positioning frame 22 . The positioning frame 22 surrounds the positioning template 21 . A positioning pattern 24 is formed on the positioning frame 22 . The positioning figure 24 is formed by removing a part or all of the positioning frame 22 along the thickness direction, or removing a part or all of the other positioning frames except the positioning figure 24 alo...

Embodiment 2

[0067] Such as Figure 11 As shown, this embodiment is based on Embodiment 1. In step e, after the second copper foil 6 located on the outermost side is processed into the second conductive circuit 61, the surface of the second conductive circuit 61 is covered with the second adhesive. junction sheet 81 and third copper foil 82 . The second bonding sheet 81 covers the second conductive circuit 61 . The position of the third copper foil 82 is determined by using the infrared positioning edge. After lamination, the third copper foil 82 is electrically connected to one or both of the second conductive circuit 61 and the first copper foil 4 by drilling and electroplating according to the position of the positioning through hole 13 . Such as Figure 12 As shown, according to the position of the positioning through hole 13, the pattern transfer process is performed on the third copper foil 82 to form the third conductive line 83.

[0068] In step f, the mechanical milling cutter...

Embodiment 3

[0071]On the basis of Embodiment 2, in step e, after processing the outermost third copper foil 82 into a third conductive circuit 83 , the surface of the third conductive circuit 83 is covered with the third bonding sheet 91 and the fourth copper foil. The third bonding sheet 91 covers the third conductive circuit 83 . After lamination, according to the position of the positioning through hole 13, drilling, electroplating, so that the fourth copper foil and one or both of the third conductive circuit 83, the second conductive circuit 61 and the first copper foil 4 are electrically connected. connect. According to the positions of the positioning through holes 13 , the pattern transfer process is performed on the fourth copper foil to form the fourth conductive lines 93 .

[0072] In step f, the mechanical milling cutter longitudinally cuts the product obtained in step e. According to the position of the positioning through hole 13 , it is determined that the cutting path do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com