Method and apparatus for recovering copper oxide from copper-containing acidic waste liquids

A technology of acid waste liquid and copper oxide, which is applied in chemical instruments and methods, copper oxide/copper hydroxide, oxidized water/sewage treatment, etc., can solve the problems of difficult treatment methods and low copper recovery rate, and achieve the goal of reducing the concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

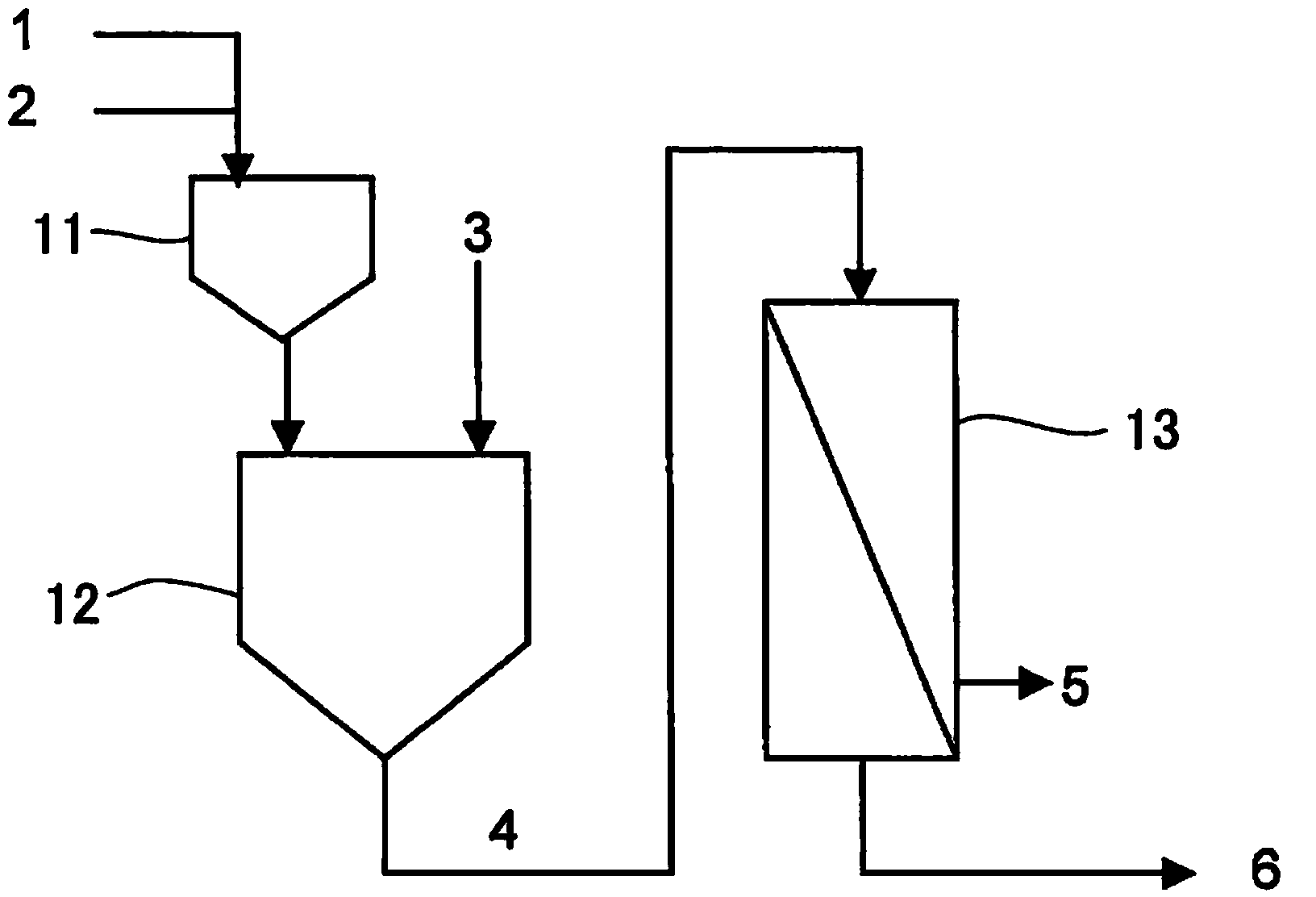

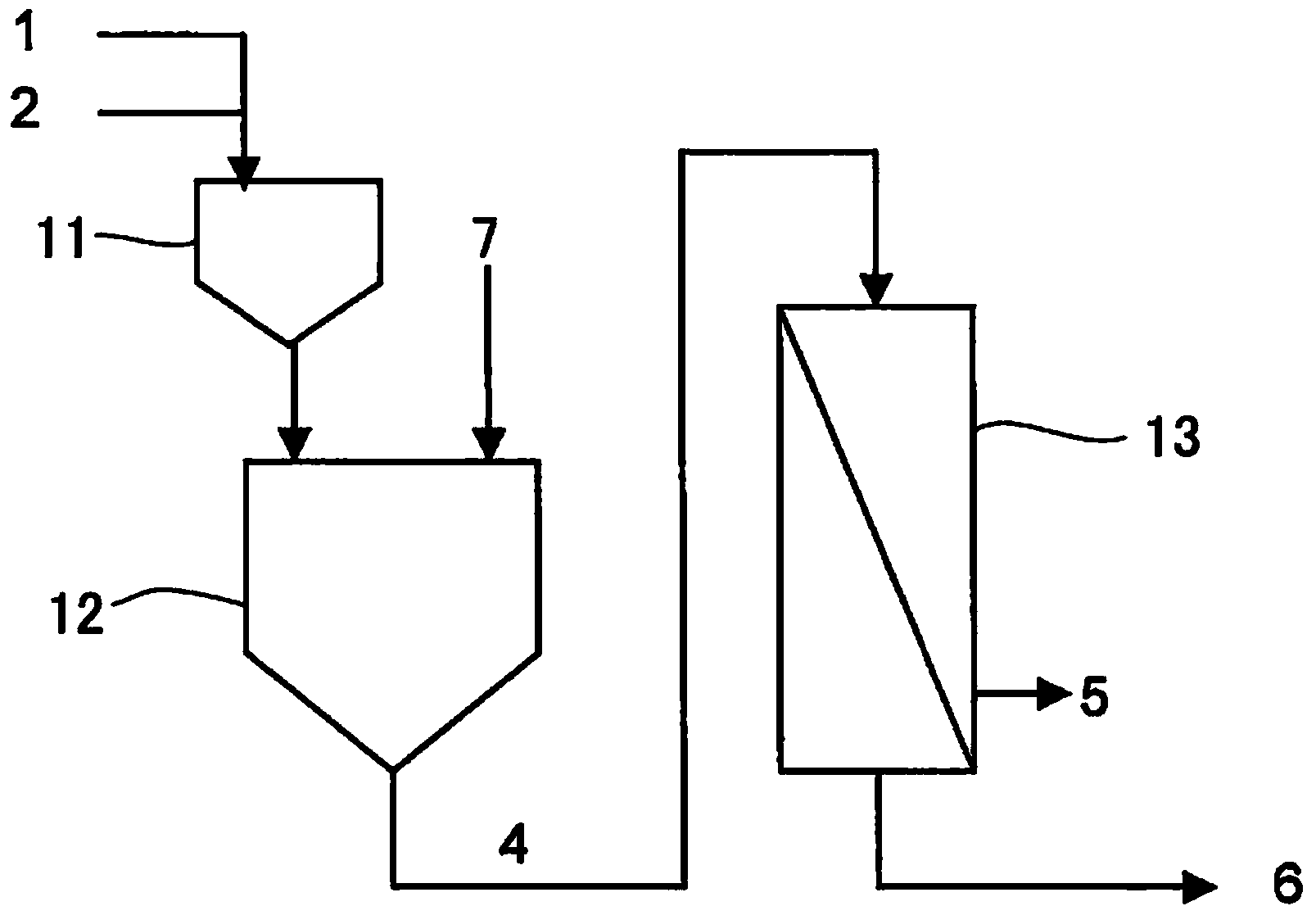

Method used

Image

Examples

Embodiment 1

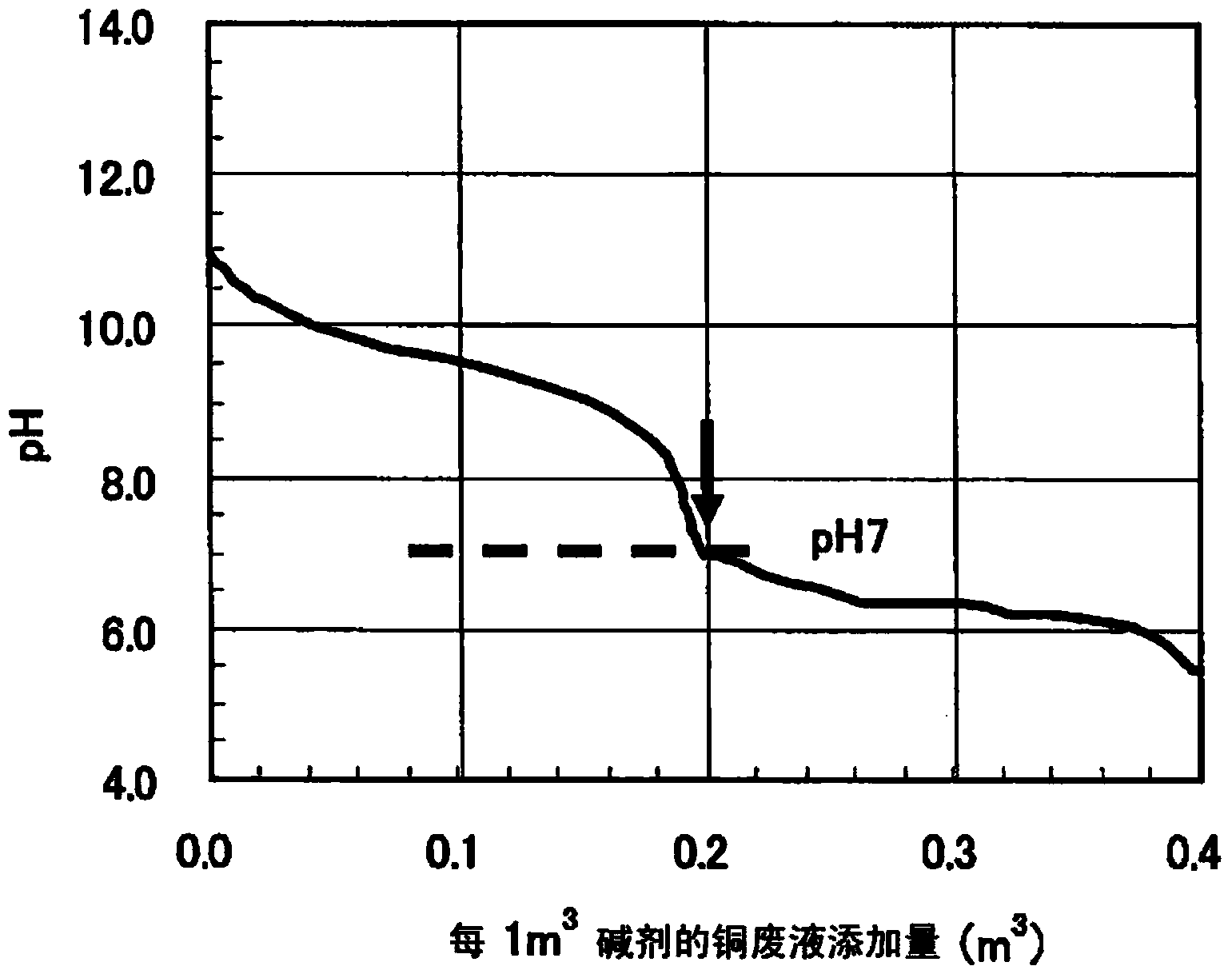

[0054] In Example 1, copper chloride etching waste liquid (hereinafter referred to as copper etching waste liquid) was used as the copper-containing acidic waste liquid, and an aqueous sodium carbonate solution was used as the alkaline agent. In order to make the pH value in the mixing reaction tank at the moment of completion of the treatment (reaction end) higher than 7, for the amount of copper etching waste liquid required to neutralize the 15% by weight sodium carbonate aqueous solution used to pH7, it is stipulated that the final flow into the mixing reaction tank The cumulative injection amount of copper etching waste liquid supplied was 0.8 equivalent of copper etching waste liquid. In addition, the injection operation of copper etching waste liquid necessary for neutralizing the sodium carbonate aqueous solution into the mixing reaction tank was performed in eight steps.

[0055]

[0056] Before the treatment, a neutralization treatment test was performed in order t...

Embodiment 2

[0062]In Example 2, a mixed solution of a 15% by weight sodium carbonate aqueous solution and a 25% by weight sodium hydroxide aqueous solution was used as an alkali agent. Same as Example 1, in order to make the pH value in the mixing reaction tank at the end of the treatment (reaction end) moment higher than 7, for the amount of copper etching waste liquid required to neutralize the alkaline agent used to pH7, determine the final mixing reaction tank. The cumulative injection amount of copper etching waste liquid supplied to the reaction tank was 0.8 equivalent of copper etching waste liquid. In addition, the injection operation of the copper etching waste liquid necessary for neutralizing the alkaline agent into the mixing reaction tank was performed in eight steps.

[0063]

[0064] Before the treatment, a neutralization treatment test was carried out in order to determine the minimum amount of alkaline agent required for the predetermined amount of copper etching waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com