A special coating agent for cucumber and its preparation method

A coating agent, cucumber technology, applied in the directions of botanical equipment and methods, seed coating/seed dressing, chemicals for biological control, etc., to achieve the effects of improving germination rate, high water holding capacity, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A special coating agent for cucumber, the weight percentage of its raw material components comprises: avermectin 2%, Bordeaux mixture 10%, fludioxonil 1%, GA 3 0.01%, Konjac Glucomannan 1%, Na 2 B 8 o 13 4H 2 O 0.5%. The rest is filled with clay.

[0020] Described coloring agent is amaranth, and coloring agent weight percent is 1.5%,

[0021] The material components of the special coating agent were mixed and ultrafinely pulverized, pulverized by a micronizer for 5 minutes, and the particles were pulverized to 20 μm. The ratio of the mass of the special coating agent to the mass of the seeds is 1:100, and the seeds are coated and dried in air.

Embodiment 2

[0023] The weight percent of its raw material component comprises: Abamectin 8%, Bordeaux mixture 20%, fludioxonil 5%, GA 3 0.015%, Konjac Glucomannan 6%, Na 2 B 8 o 13 4H 2 O 3%. The rest is filled with clay.

[0024] The colorant is a mixture of amaranth, carmine and erythrosine, and the weight percentage of the colorant is 1.5-5%.

[0025] The preparation method is as follows: the special coating agent is mixed according to the material components for ultrafine pulverization, pulverized by a micronizer for 10 minutes, and the particles are pulverized to 120 μm. The ratio of the mass of the special coating agent to the mass of the seeds is 1:300, and the seeds are coated and dried in air.

Embodiment 3

[0027] The percentage by weight of its raw material components of a special coating agent for cucumber comprises: konjac glucomannan 4%, abamectin 5%, Bordeaux mixture 15%, fludioxonil 3%, GA 3 0.01%, Na 2 B 8 o 13 4H 2 O 2%. The rest is filled with clay.

[0028] Described coloring agent is tartrazine, and coloring agent weight percentage is 3%.

[0029] The material components of the special coating agent were mixed and ultrafinely pulverized, pulverized by a micronizer for 7 minutes, and the particles were pulverized to 80 μm. The ratio of the mass of the special coating agent to the mass of the seeds is 1:200, and the seeds are coated and dried in air.

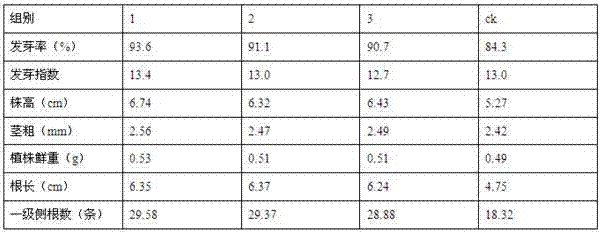

[0030] Analysis of seed germination and growth under different treatments. The cucumber seeds treated with the coating agent in Examples 1-3 were taken as the experimental groups, which were respectively recorded as experimental groups 1, 2, and 3, and the cucumber seeds of the control group were not subjected to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com