Method for extracting and purifying flavones from plants containing flavones

A technology of flavonoids and plants, applied in the field of extraction of bioflavonoids, can solve the problems of difficult application, good separation effect, clean process, etc., and achieve the effect of reducing extraction cost, increasing extraction rate, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

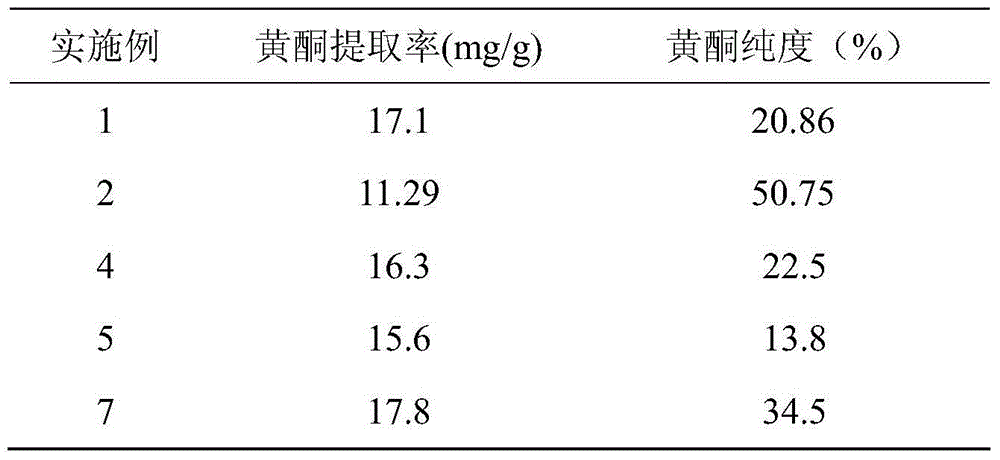

Examples

Embodiment 1

[0022] Collect fresh bamboo leaves, wash and dry them, and crush them to 60 mesh for later use. Put the bamboo leaf powder into the Erlenmeyer flask, add 60% ethanol aqueous solution, the ratio is 1:20 (g / g), the mass fraction is 0.9% surfactant-sodium dodecylsulfonate, and soak for 0.5h. Put the Erlenmeyer flask into a microwave oven, set the microwave power to 450W and the extraction time to 1min. After the microwave extraction was completed, the Erlenmeyer flask was taken out and cooled to room temperature, and then filtered under reduced pressure to obtain the filtrate for use. The ethanol and water in the filtrate are evaporated and recovered to obtain a concentrated solution 1, the concentration of flavonoids in the concentrated solution 1 is about 1 mg / ml, and the concentrated solution 1 is freeze-dried to obtain crude flavonoid particles. The resulting concentrated solution 1 is absorbed by the macroporous resin AB-8, analyzed with 2 times the bed volume of 95% ethano...

Embodiment 2

[0024]Similar to case 1, but without adding surfactant. Fresh bamboo leaves were collected, washed and dried, and crushed to 45 mesh for use. Put the bamboo leaf powder into a conical flask, add 60% ethanol aqueous solution at a ratio of 1:50 (g / g), and soak for 0.5h. Put the Erlenmeyer flask into a microwave oven, set the microwave power to 225W and the extraction time to 2min. After the microwave extraction was completed, the Erlenmeyer flask was taken out and cooled to room temperature, and then filtered under reduced pressure to obtain the filtrate for use. The ethanol and water in the filtrate are evaporated and recovered to obtain a concentrated solution 1, the concentration of flavonoids in the concentrated solution 1 is about 1 mg / ml, and the concentrated solution 1 is freeze-dried to obtain crude flavonoid particles. The resulting concentrated solution 1 is absorbed by the macroporous resin AB-8, analyzed with 2.5 times the bed volume of 95% ethanol solution, and th...

Embodiment 3

[0026] Fresh bamboo leaves were collected, washed and dried, and crushed to 45 mesh for use. Put the bamboo leaf powder into a conical flask, add 60% ethanol aqueous solution, the ratio is 1:20 (g / g), and the mass fraction is 0.5% surfactant-sodium dodecylbenzenesulfonate, soak for 0.5h . Put the Erlenmeyer flask into a microwave oven, set the microwave power to 150W and the extraction time to 1min. After the microwave extraction was completed, the Erlenmeyer flask was taken out and cooled to room temperature, and then filtered under reduced pressure to obtain the filtrate for use. The ethanol and water in the filtrate are evaporated and recovered to obtain a concentrated solution 1, the concentration of flavonoids in the concentrated solution 1 is about 1 mg / ml, and the concentrated solution 1 is freeze-dried to obtain crude flavonoid particles. The resulting concentrated solution 1 is absorbed by the macroporous resin AB-8, analyzed with 2 times the bed volume of 95% ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com