Energy-saving and efficient solid catalyst atomizing and drying system

A solid catalyst, atomization drying technology, applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problems of short drying time, effective components of dried materials, sticking to the inner wall of the drying tower, affecting the quality of catalyst powder, etc., to improve the purity and quality, simple and reliable structure, easy disassembly, assembly, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

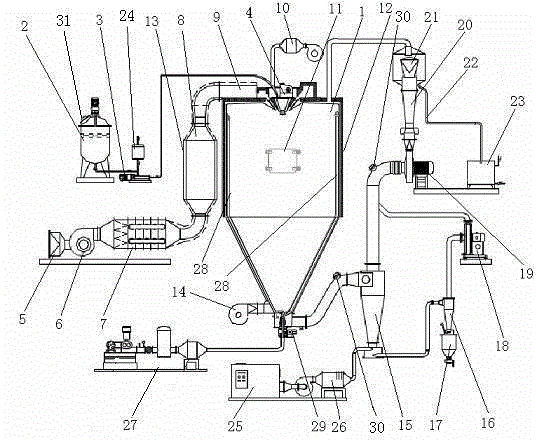

[0015] Example 1: Such as figure 1 As shown, an energy-saving and high-efficiency solid catalyst atomization drying system includes a drying tower 1 with a vertical cylindrical structure, a feeding device, a heating device, a rheumatic cooling device, a discharging device, a waste gas recycling device and an intelligent control cabinet , the top of the drying tower 1 is provided with a hot air distributor 9, and an electric high-speed centrifugal atomizer 4 is installed on the inner central axis of the top of the drying tower 1, and a circle of heat preservation shell 12 is arranged around the tower body outside the drying tower body ; The material tank 2 of the feeding device is connected to the top feed inlet of the drying tower by a pressure pump 3, and is provided with a primary air cooling device 10 at the feed inlet, which is used to dry the material slurry, further improving the drying efficiency of the drying tower. The solid content of the slurry in the tower; the f...

Embodiment 2

[0016] Example 2: Such as figure 1 As shown, as an improvement of the present invention, a cleaning device is provided in the drying system, and the cleaning device includes a rotary cleaning device 27 arranged at the bottom of the drying tower and a clean water tank 24 placed next to the material tank. Use the cleaning device to regularly clean and flush the entire system to avoid contamination between materials when drying different types of solid catalysts, thereby improving the purity of the product and prolonging the service life of the equipment in the system to a certain extent. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0017] Example 3: Such as figure 1 As shown, as an improvement of the present invention, the inner wall of the drying tower body is lined with a hydrophobic layer. The body of the drying tower is mostly made of stainless steel, carbon steel or reinforced concrete. These materials are hydrophilic and are easy to be adhered by wet materials and scarred. Therefore, evenly brushing a layer of hydrophobic layer on the inner wall of the tower body can effectively reduce the probability of scarring of the spray drying tower. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com