TiO2-quantum-dot-and-MoS2-nanometer-flower-combined heterojunction semiconductor material and preparation method thereof

A nanoflower and heterojunction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inappropriate large-scale industrial production, complex synthesis process, high production cost, etc. High repeatability, reduced complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

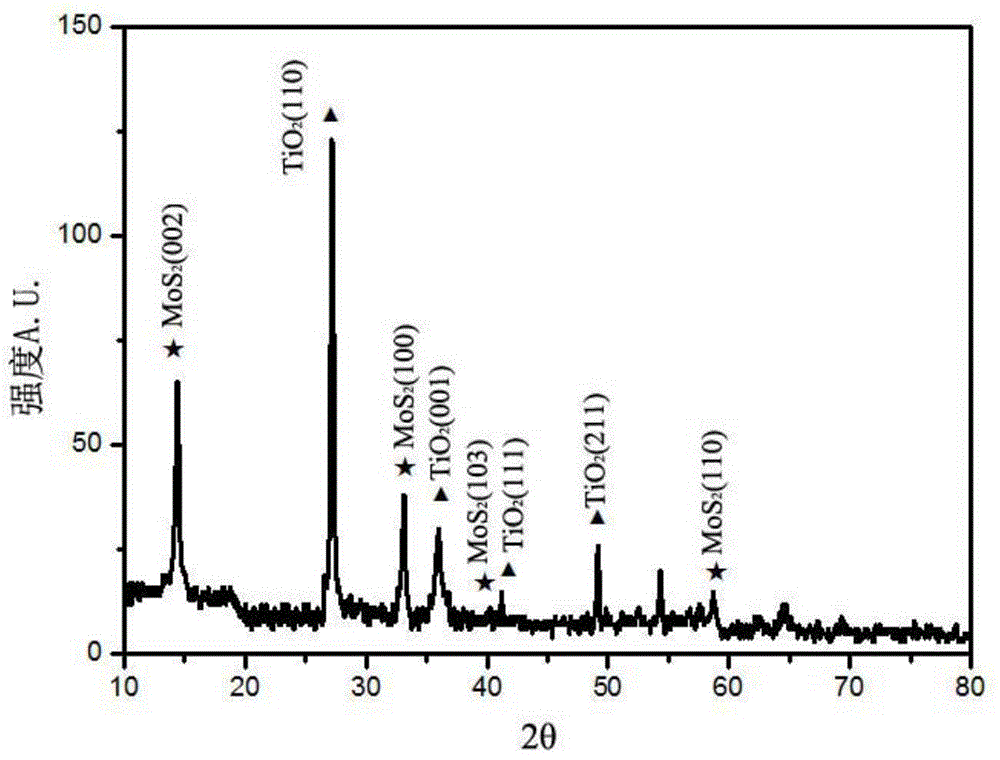

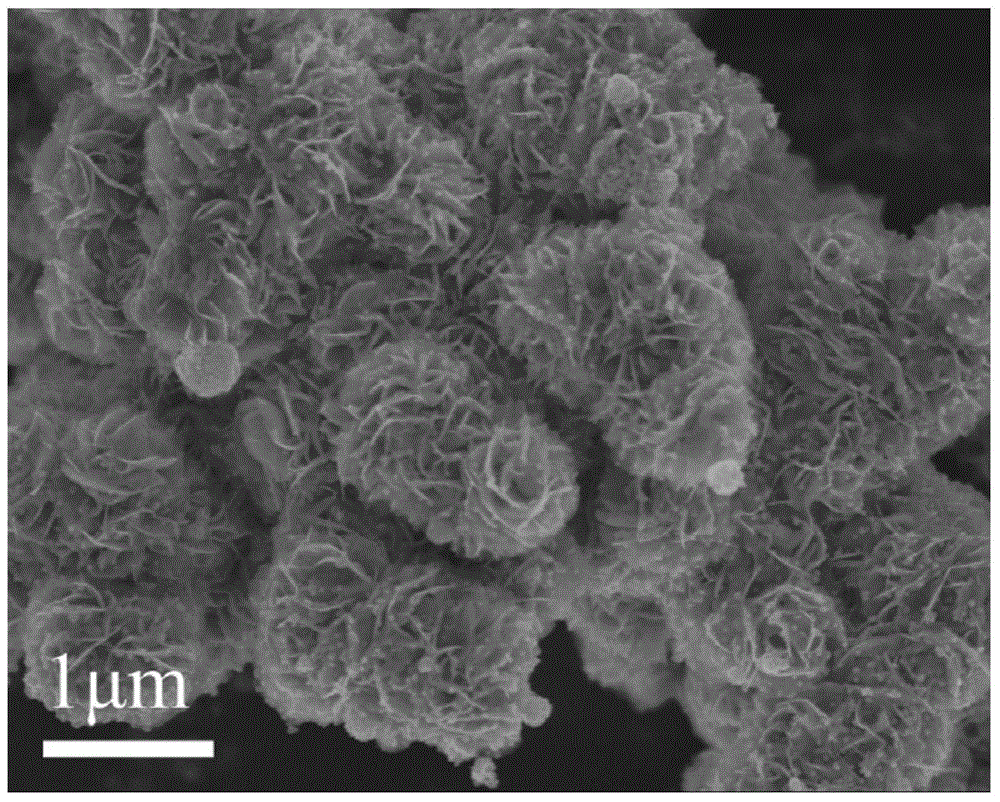

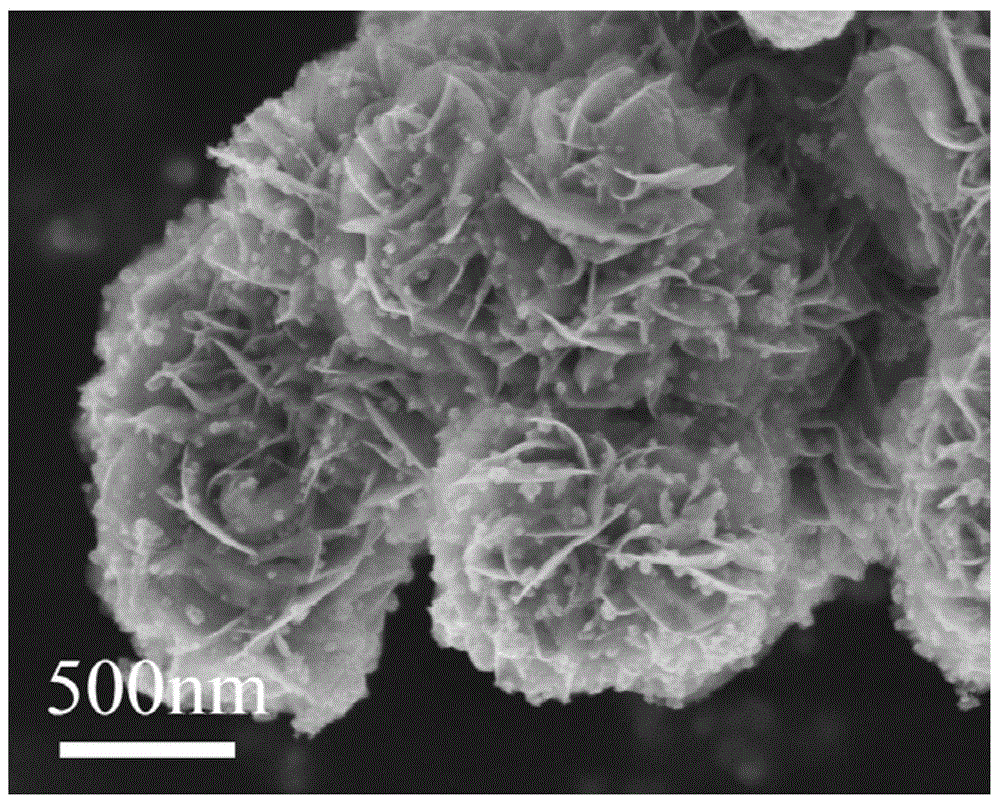

[0037] Embodiment 1 prepares TiO 2 Quantum dot composite MoS 2 Nanoflower Heterojunction Semiconductor Materials

[0038] The specific steps of preparation are as follows:

[0039] (1) Dissolve 1g of sodium molybdate, 1.4g of thiourea and 1.4g of thiourea into 80mL of deionized water, add about 0.33g of oxalic acid to make the pH of the solution less than 1, and stir thoroughly.

[0040] (2) After stirring for more than 15 minutes, add the mixed solution into a 100mL reaction kettle, seal it, then put it into a vacuum oven and heat it at 200°C for 24 hours, and cool to room temperature after the reaction.

[0041] (3) Collect and remove the black precipitate at the bottom of the reaction kettle and the black adhesion on the inner wall, and wash it repeatedly with deionized water until the supernatant is completely clear.

[0042] (4) Pour off the supernatant, put the pure sample in a vacuum oven at 50° C. for 6 hours and take it out after drying to obtain a black powder.

...

Embodiment 2

[0048] Embodiment 2 The present invention wave TiO 2 Quantum dot composite MoS 2 Field Emission Performance Test of Nanosphere Composite Heterojunction Semiconductor Materials

[0049] The TiO of the present invention that above-mentioned embodiment 1 prepares 2 Quantum dot composite MoS 2 Nanoflower heterojunction semiconductor material, due to its large specific surface area, forms a p-n junction at the junction, and the distribution of a large number of quantum dots is conducive to electron excitation, making it more effective than pure MoS 2 The photocatalytic performance of nanoflowers has been significantly improved. TiO of the present invention 2 Quantum dot composite MoS 2 Nanoflower heterojunction semiconductor materials and MoS 2 Field emission performance test of nanoflowers, including specific steps:

[0050] (1) get TiO of the present invention respectively 2 Quantum dot composite MoS 2 Nanoflower heterojunction semiconductor materials and pure MoS 2 Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com