Energy-saving and pollution-resisting water treatment system provided with RO (reverse osmosis) membranes and application of water treatment system

A water treatment system and reverse osmosis membrane technology, applied in osmosis/dialysis water/sewage treatment, water/sewage treatment, water/sewage treatment equipment, etc. pressure loss and other problems, to achieve the effect of enhancing anti-pollution ability, short duration and saving pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

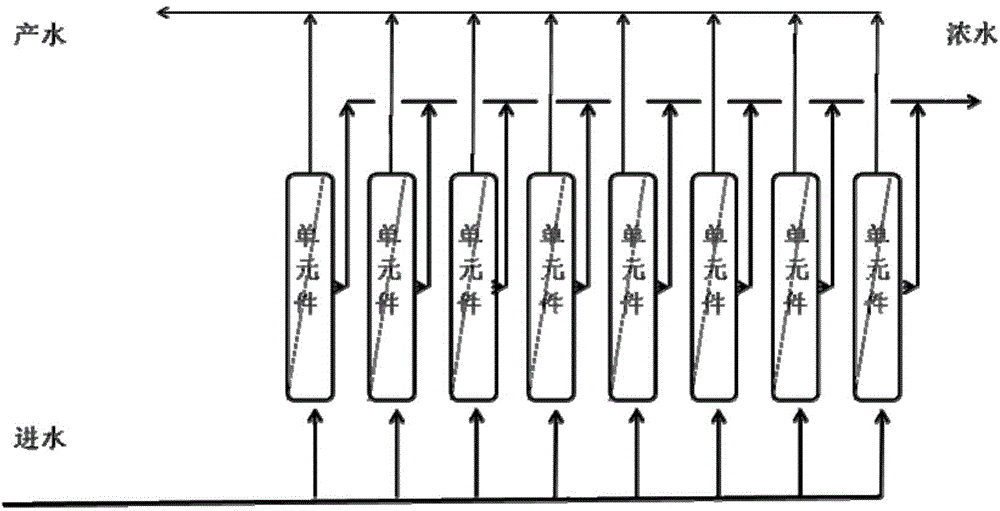

[0029] Such as figure 1 , 2 The shown water treatment system includes a raw water tank for storing raw water, and the raw water tank is respectively connected to the main raw water pipeline and the main concentrated water pipeline (used to feed back the concentrated water of the reverse osmosis membrane element to the raw water tank).

[0030] 10 reverse osmosis membrane elements are arranged in parallel, and are respectively connected to their respective branch raw water pipelines, branch product water pipelines and branch concentrated water pipelines. .

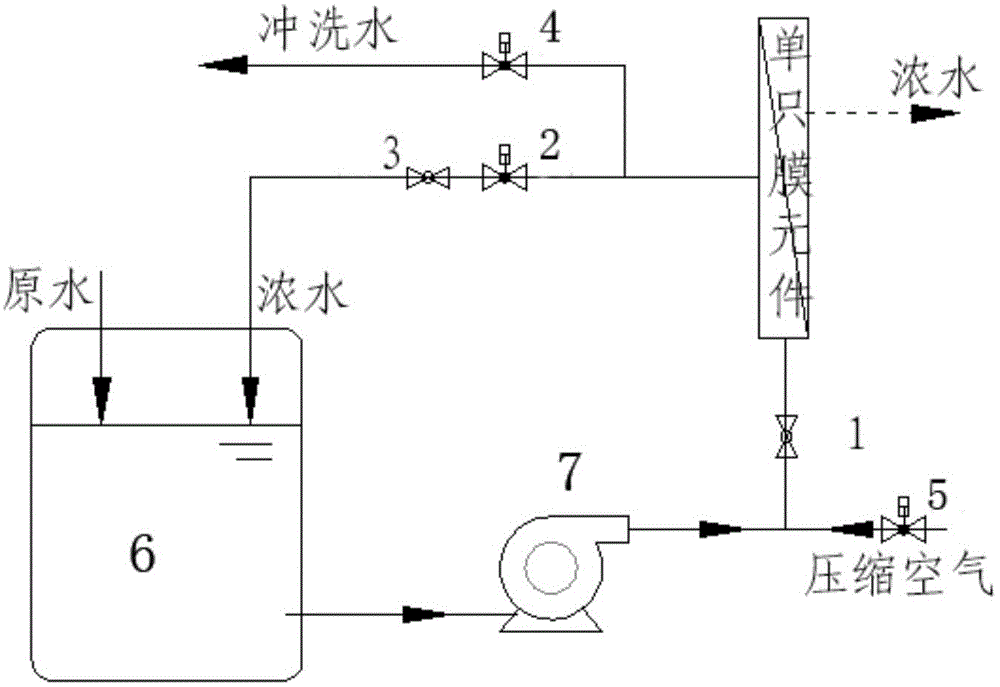

[0031] The system water inlet valve 1 is set on the branch raw water pipeline, and the branch raw water pipeline converges with the compressed air pipeline upstream of the system water inlet valve 1 to obtain the air-water mixture for flushing.

[0032] Concentrated water return valve 2 and concentrated water regulating valve 3 are set on branch concentrated water pipeline. In addition, a flushing water discharge pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com