Plastering gypsum special for autoclaved aerated concrete products

A technology of concrete products and plastering plaster, which is applied in the field of building wall materials, can solve problems such as weak adhesion between mortar and wall materials, large shear stress on the surface of mortar and wall, and shedding, so as to improve safety and Comfort, reduce cracking and peeling, and improve the effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

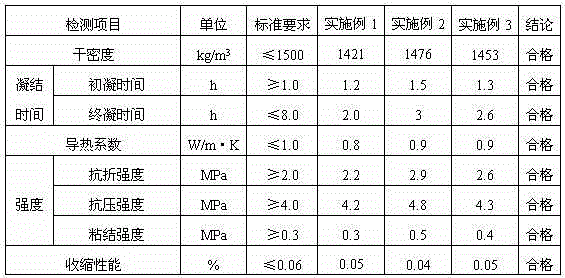

Embodiment 1

[0024] A special plastering gypsum for autoclaved aerated concrete products. The mortar contains the following components in mass ratio: 250kg of construction gypsum, 700kg of fine sand, 1.0kg of water reducer, 0.3kg of retarder, 0.7kg of water retaining agent, Adhesive 0.5kg, fiber material 1.0kg. The building gypsum is the product obtained after drying the solid waste desulfurization gypsum of the power plant, calcining at 210°C for 2 hours, ball milling for 2 minutes, and aging for 3 days. The product quality meets the S 3.0 standard in GB / T 9776-2008. The fine Sand fineness ≥ 28 mesh, mud content ≤ 0.5%. The water reducer is a high-efficiency polycarboxylate water reducer with a water reducing rate ≥ 25%. The retarder is protein gypsum retarder (purchased from Zhengzhou Paini Chemical Reagent Factory). The water retaining agent is hydroxypropyl methylcellulose with a viscosity of 100000 mPa.s. The tackifier is dispersible latex powder. The fiber material is polypropyle...

Embodiment 2

[0026] A special plaster for autoclaved aerated concrete products. The mortar contains the following components in mass ratio: 280kg of construction gypsum, 750kg of fine sand, 1.0kg of water reducer, 0.5kg of retarder, 1.0kg of water retaining agent, Adhesive 0.6kg, fiber material 1.1kg. The building gypsum is the product obtained after drying the desulfurized gypsum solid waste from power plants, calcining at 210°C for 2 hours, ball milling for 2 minutes, and aging for 3 days. The product quality meets the S 3.0 standard in GB / T 9776-2008. The fineness of fine sand is ≥28 mesh, and the mud content is ≤0.5%. The water reducer is a high-efficiency polycarboxylate water reducer with a water reducing rate ≥ 25%. The retarder is a protein gypsum retarder. The water retaining agent is hydroxypropyl methylcellulose with a viscosity of 100000 mPa.s. The tackifier is dispersible latex powder. The fiber material is polypropylene fiber with an aspect ratio of 100 and an average dia...

Embodiment 3

[0028] A special plaster for autoclaved aerated concrete products. The mortar contains the following mass ratio components: 300kg of construction gypsum, 720kg of fine sand, 1.2kg of water reducer, 0.4kg of retarder, 0.8kg of water retaining agent, Adhesive 0.7kg, fiber material 1.2kg. The building gypsum is the product obtained after drying the desulfurized gypsum solid waste from power plants, calcining at 210°C for 2 hours, ball milling for 2 minutes, and aging for 3 days. The product quality meets the S 3.0 standard in GB / T 9776-2008. The fineness of fine sand should be ≥28 mesh, and the mud content should be ≤0.5%. The water reducer is a high-efficiency polycarboxylate water reducer with a water reducing rate ≥ 25%. The retarder is a protein gypsum retarder. The water retaining agent is hydroxypropyl methylcellulose with a viscosity of 100000 mPa.s. The tackifier is dispersible latex powder. The fiber material is polypropylene fiber with an aspect ratio of 100 and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com