Preparation method of high-temperature-resistant block-shaped SiO2-Al2O3 composite aerogel thermal insulation material

A sio2-al2o3 and composite aerogel technology, which is applied in the field of preparation of high temperature resistant bulk SiO2-Al2O3 composite aerogel thermal insulation materials, can solve problems such as complex preparation processes, and achieves simple process, good stability, and reduced cost. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

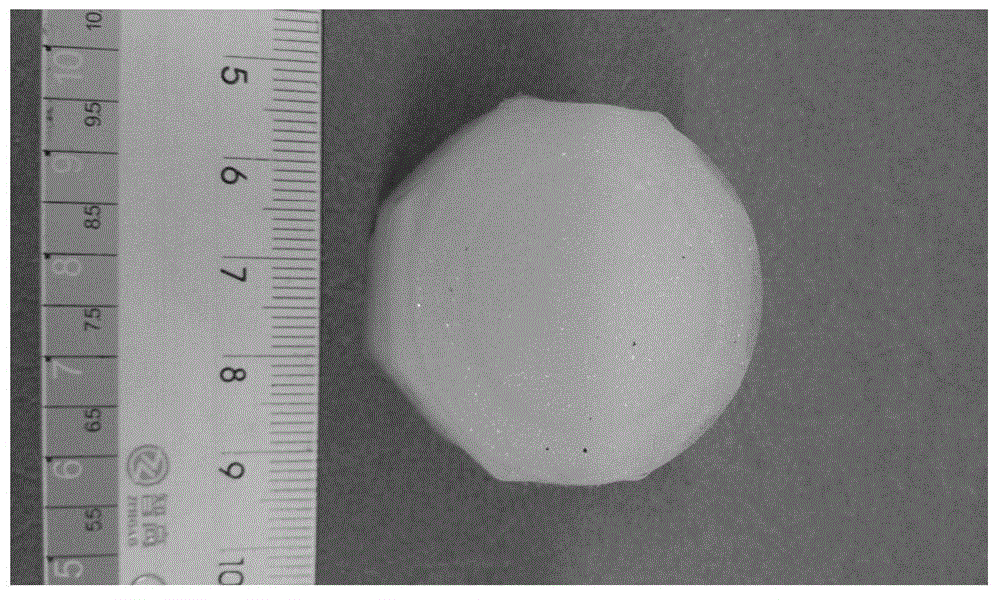

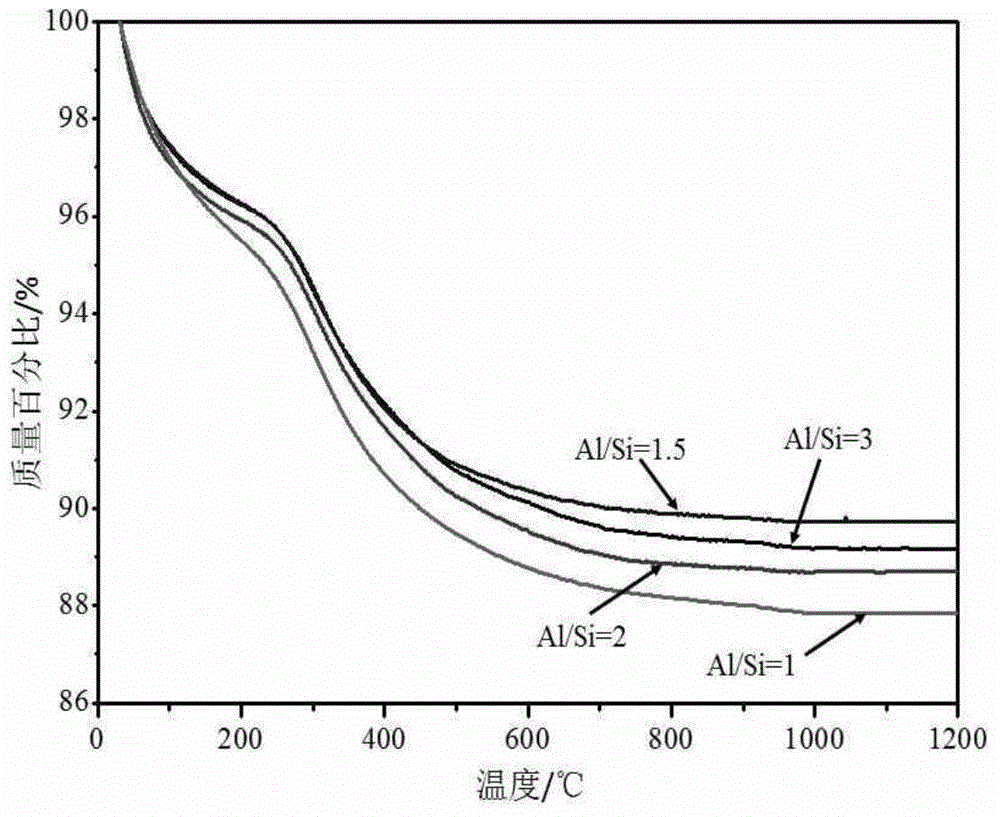

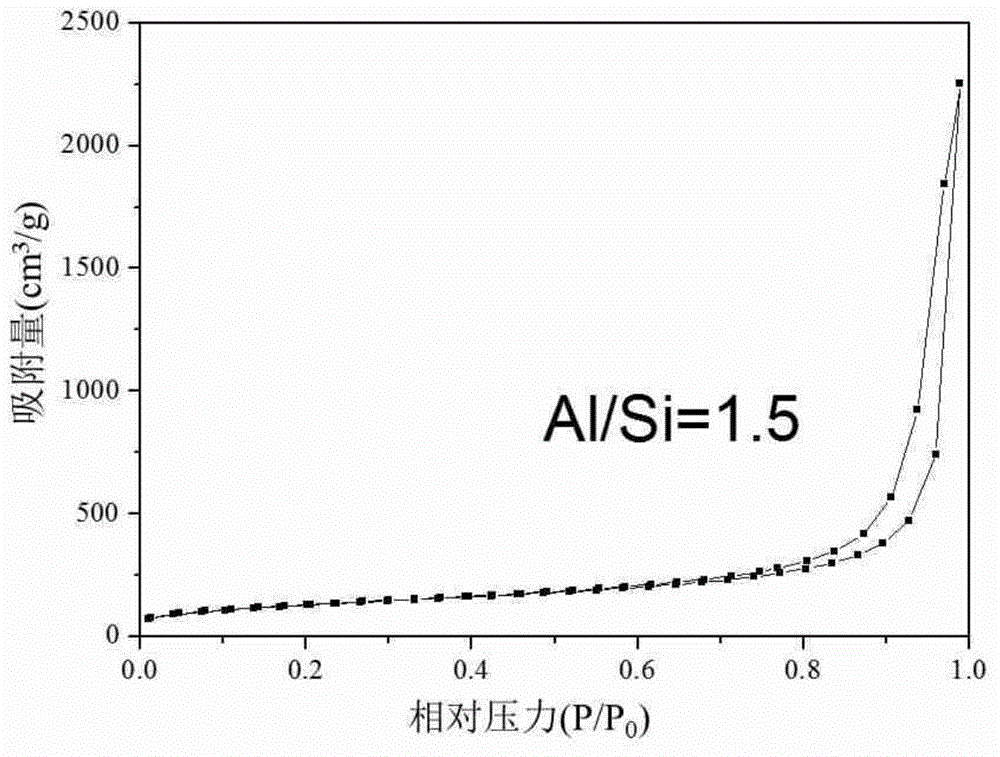

example 1

[0026] Mix tetraethyl orthosilicate, ethanol, water, and hydrochloric acid uniformly at a molar ratio of 1:10:4:0.003, stir at 50°C for 2 hours, and fully hydrolyze to obtain SiO 2 Sol. After mixing aluminum chloride hexahydrate (crystalline aluminum chloride), ethanol, and water according to the molar ratio of 1:24.7:42.1, stir for half an hour to fully hydrolyze the crystalline aluminum chloride to obtain Al 2 o 3 Sol. Then the above SiO 2 Sol and Al 2 o 3 The sol was mixed evenly according to the molar ratio of tetraethyl orthosilicate and crystalline aluminum chloride as 1:3, then stirred for 10 minutes, and then propylene oxide was added, wherein the molar ratio of propylene oxide to inorganic aluminum salt was 8.56:1, and after stirring for 30 minutes, the The mixed sol was poured into the mold and gelled in about 2 hours. SiO obtained above 2 -Al 2 o 3 After the composite wet gel was left at room temperature for 10 hours, it was aged and replaced by ethanol agi...

example 2

[0028] After mixing tetraethyl orthosilicate, ethanol, water, and hydrochloric acid uniformly at a molar ratio of 1:16:5:0.004, stir at 50°C for 2 hours to obtain SiO after fully hydrolyzing 2 Sol. Stir aluminum nitrate nonahydrate (crystalline aluminum nitrate), ethanol, and water at a molar ratio of 1:8.5:40 for half an hour to fully hydrolyze crystalline aluminum nitrate to obtain Al 2 o 3 Sol. Then the above SiO 2 Sol and Al 2 o 3 The sol was mixed evenly according to the molar ratio of tetraethyl orthosilicate and crystalline aluminum nitrate as 1:2, then stirred for 10 minutes, and then added butylene oxide, wherein the molar ratio of propylene oxide and inorganic aluminum salt was 8.56:1, and after stirring for 30 minutes, the The mixed sol was poured into the mold and gelled in about 3 hours. SiO obtained above 2 -Al 2 o 3 After the composite wet gel was left at room temperature for 12 hours, it was aged and replaced by ethanol / tetraethyl orthosilicate mixed a...

example 3

[0030] Mix tetraethyl orthosilicate, ethanol, water, and hydrochloric acid uniformly at a molar ratio of 1:18:4:0.003, stir at 50°C for 1.5 hours, and fully hydrolyze to obtain SiO 2 Sol. Mix aluminum chloride hexahydrate, ethanol, and water according to the molar ratio of 1:19.3:45 for half an hour to fully hydrolyze aluminum chloride hexahydrate to obtain Al 2 o 3 Sol. Then the above SiO 2 Sol and Al 2 o 3 The sol was mixed evenly according to the molar ratio of tetraethyl orthosilicate and aluminum chloride hexahydrate as 2:3, then stirred for 15 minutes, and then added propylene oxide, wherein the molar ratio of propylene oxide and inorganic aluminum salt was 10:1, and after stirring for 30 minutes, Pour the mixed sol into the mold and gel in about 3 hours. SiO obtained above 2 -Al 2 o 3 After the composite wet gel was left at room temperature for 15 hours, it was aged and replaced by ethanol / tetraethyl orthosilicate mixed aging solution in an oven at 50°C for 7 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com