A kind of preparation method of pressureless silicon carbide bearing ball

A technology of pressureless silicon carbide and bearing balls, which is applied in the field of preparation of new pressureless silicon carbide bearing balls, and can solve problems such as low process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

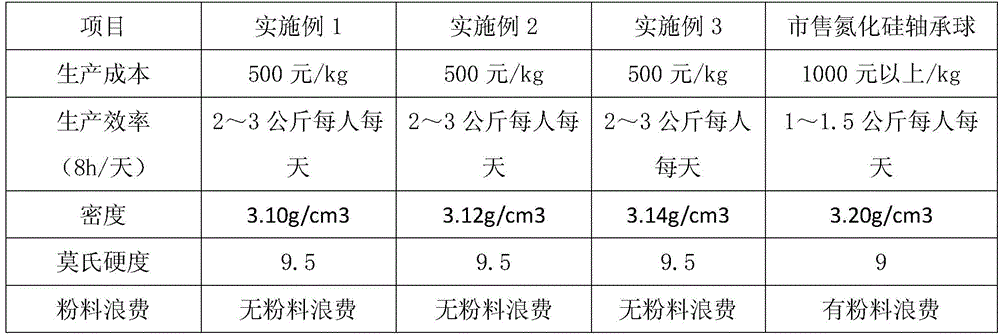

Examples

preparation example Construction

[0012] A method for preparing a new type of pressureless silicon carbide bearing ball using the above-mentioned silicon carbide granulated powder, which uses silicon carbide granulated powder as a raw material, and the preparation method steps are as follows:

[0013] (1) Pre-pressing: Fill the silicon carbide granulated powder into half of the mold, scrape off the excess silicon carbide granulated powder, and press it into a spherical blank of silicon carbide bearing ball with a hydraulic forming machine;

[0014] (2) Vacuum packaging: vacuum packaging the spherical blanks of silicon carbide bearing balls press-formed in step (1);

[0015] (3) Isostatic pressing: After packaging, isostatic pressing is performed, and the bearing ball body is produced after isostatic pressing;

[0016] (4) Drying: Dry the prepared bearing ball body at 40-80°C for 10-30 hours;

[0017] (5) Sintering: The dried silicon bearing ball is heated to 2060-2120°C for 60-180 minutes in a vacuum state, and argon is...

specific Embodiment approach

[0032] The following embodiments further limit the present invention, but are not limited thereto.

[0033] The raw materials used in the examples are silicon carbide powder, phenolic resin, carbon black, graphite, boron carbide, and polyvinyl alcohol.

[0034] The hydraulic forming machine in the embodiment was purchased from Ningbo Jianke Hydraulic Machinery Manufacturing Company, model YA800.

[0035] The vacuum packaging machine was purchased from Shandong Zhucheng Zhengtai Machinery Co., Ltd., model DZ-400 / 2L vacuum packaging machine,

[0036] The isostatic press was purchased from Shanxi Jinkaiyuan Industrial Co., Ltd., model: KJYo500 cold isostatic press.

Embodiment 1

[0038] A new type of preparation method of pressureless silicon carbide bearing ball, using silicon carbide granulated powder as raw material, said silicon carbide granulated powder includes the following material components in mass percentage: silicon carbide powder 76%, phenolic resin 10%, Carbon black 2%, graphite 2%, boron carbide 1%, polyvinyl alcohol 10%;

[0039] The preparation steps of the raw material of silicon carbide granulated powder are as follows:

[0040] Take silicon carbide powder, phenolic resin, carbon black, graphite, and boron carbide and mix them evenly, then add polyvinyl alcohol with a mass concentration of 11% to 19% and deionized water and mix them evenly. Add ammonia with a mass concentration of 25% to adjust the Ph value. The addition amount is 0.1%% of the mass of silicon carbide powder, phenolic resin, carbon black, graphite, and boron carbide mixture. The addition amount of deionized water is the mass of silicon carbide powder, phenol resin, carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com