Advanced alkane purifying method for removing impurities

A technology for deep purification and alkanes, applied in chemical instruments and methods, purification/separation of hydrocarbons, organic chemistry, etc., can solve problems such as desulfurization and deoxygenation that are not mentioned, and reduce unit consumption and reduce Effects of energy consumption and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

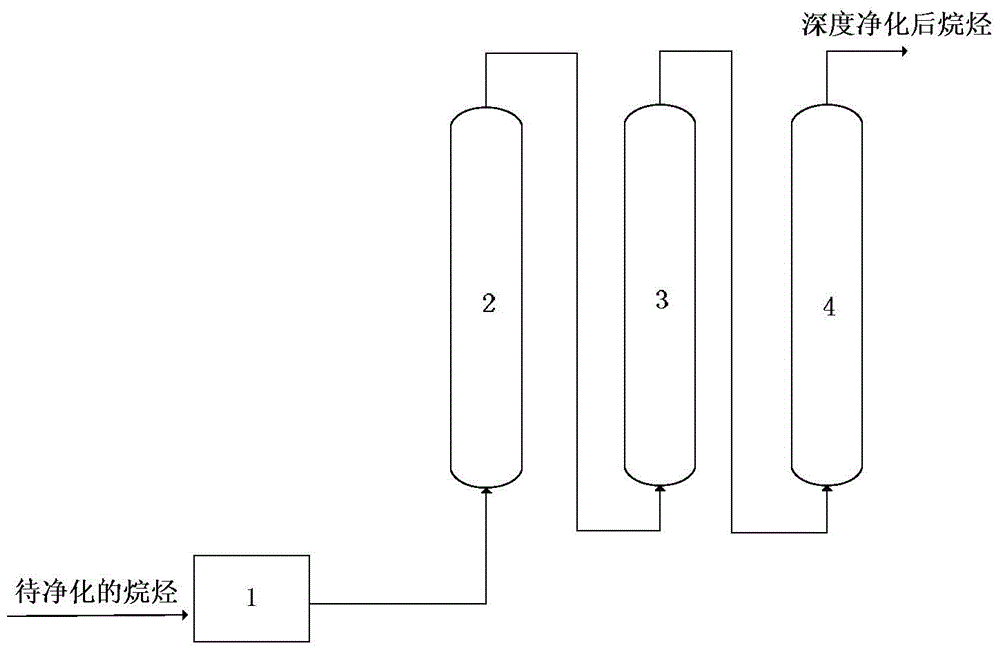

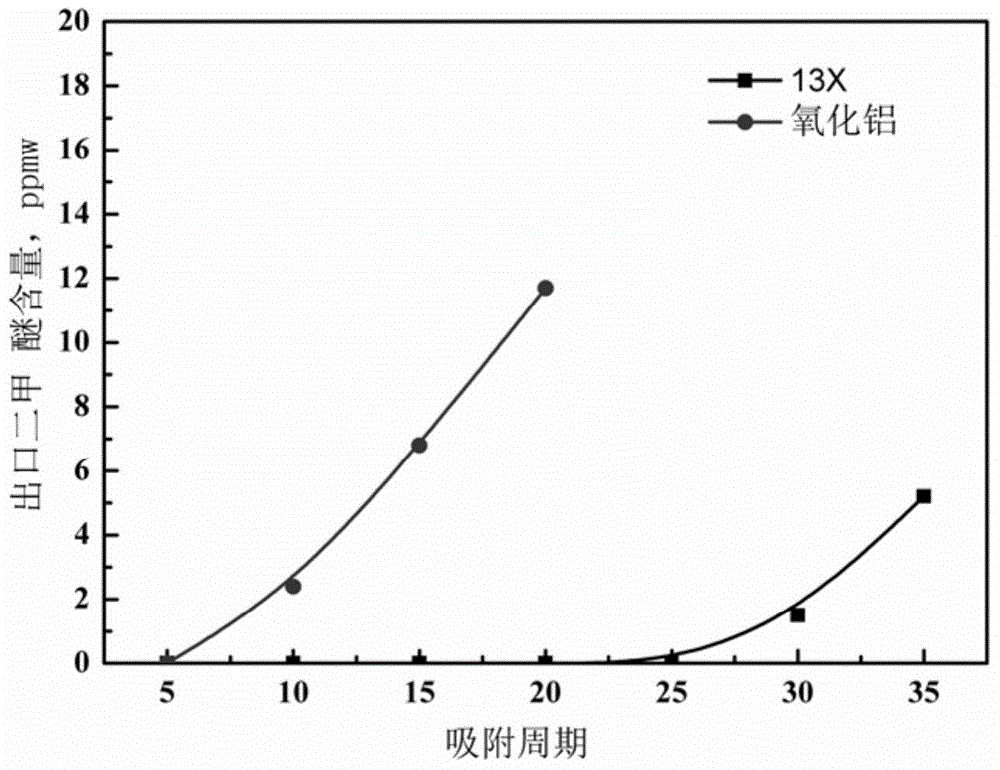

[0042] The alkane to be purified in the present invention includes C produced by FCC 3 -C 5 Fractions, which contain sulfides (including H 2 S, COS, mercaptans and disulfides, etc.) and a small amount of sulfur-free polar compounds (including methanol, dimethyl ether, acetone, etc.), such as figure 1 As shown, the deep purification method of alkane impurities of the present invention may comprise the following steps:

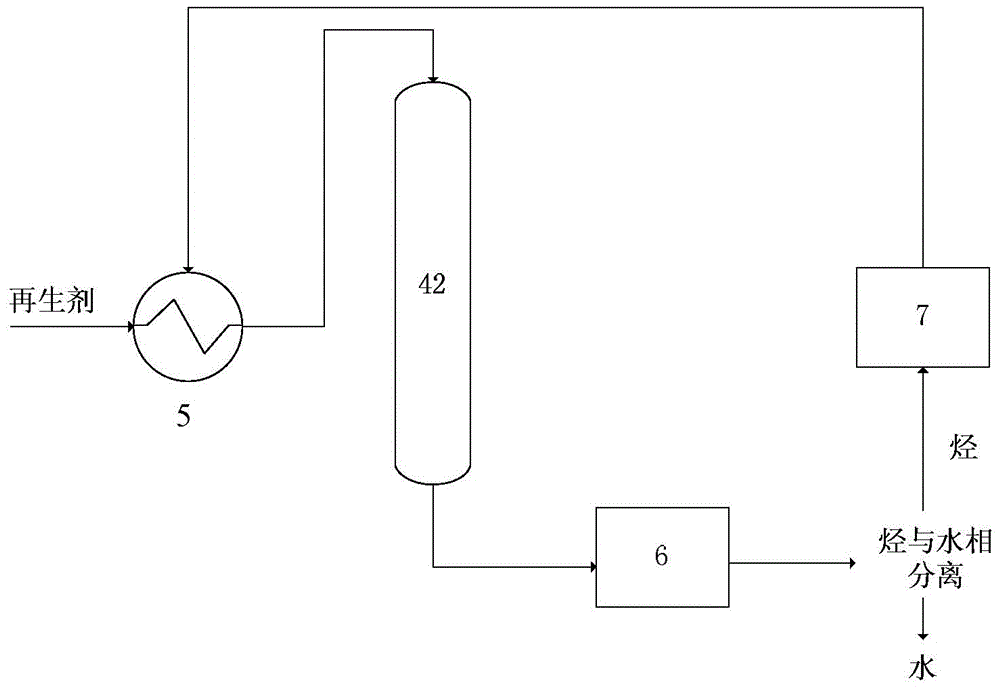

[0043] (1) Make the alkane flow to be purified enter the alkali cleaning treatment unit 1 through the pipeline, and in the alkali cleaning treatment unit 1, the alkane flow to be purified and the alkali solution are at a temperature of 15° C.-66° C. at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com