Self-cleaning water-based woodware finish paint and preparation method thereof

A self-cleaning, water-based technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of small application range, poor transparency, low photocatalytic activity, etc., and achieve low cost, adjustable size, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

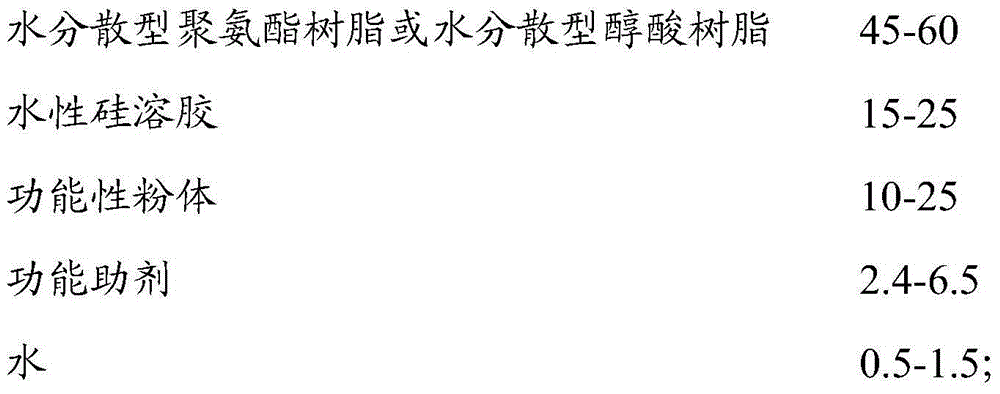

[0044] A kind of water-based self-cleaning wood topcoat of the present embodiment comprises the raw material of following weight portion:

[0045]

[0046]

[0047] The preparation method is as follows:

[0048] (1) adding water-based silica sol and functional powder to the reactor in sequence for blending to obtain self-cleaning water-based silica sol;

[0049] (2) Water-dispersed polyurethane resin or water-dispersed alkyd resin, functional additives, self-cleaning water-based silica sol and water obtained in step (1) are added to the reactor and blended successively, and are dispersed at high speed and sand-milled for 200 mesh filter screen to obtain the self-cleaning water-based wood finish paint.

[0050] The average particle size of the aqueous silica sol used in this example is 22nm. The average particle size of the nanoscale talcum powder, nanoscale kaolin and nanoscale talc powder used is 6 μm. The prepared water-based self-cleaning wood topcoat has good comp...

Embodiment 2

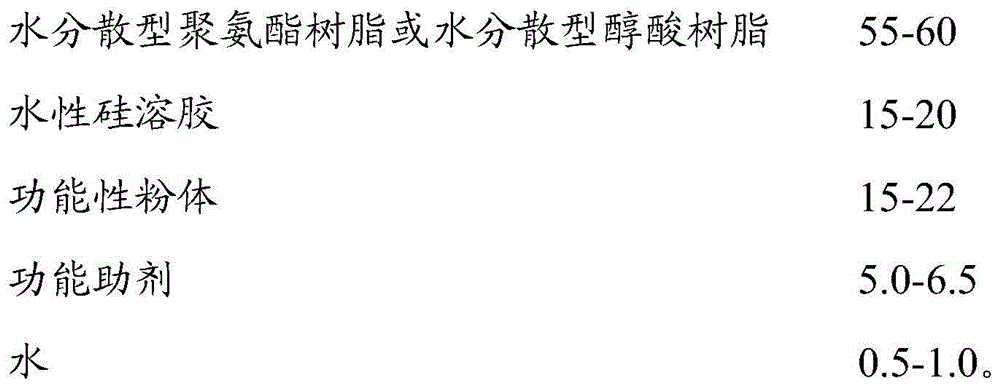

[0052] A kind of water-based self-cleaning wood topcoat of the present embodiment comprises the raw material of following weight portion:

[0053]

[0054]

[0055] The preparation method is as follows:

[0056] (1) adding water-based silica sol and functional powder to the reactor in sequence for blending to obtain self-cleaning water-based silica sol;

[0057] (2) Water-dispersed polyurethane resin or water-dispersed alkyd resin, functional additives, self-cleaning water-based silica sol and water obtained in step (1) are added to the reactor and blended successively, and are dispersed at high speed and sand-milled for 200 mesh filter screen to obtain the self-cleaning water-based wood finish paint.

[0058] The average particle size of the aqueous silica sol used in this example is 32nm. The average particle size of the nanoscale talcum powder, nanoscale kaolin and nanoscale talc powder used is 5 μm. The prepared water-based self-cleaning wood topcoat has good comp...

Embodiment 3

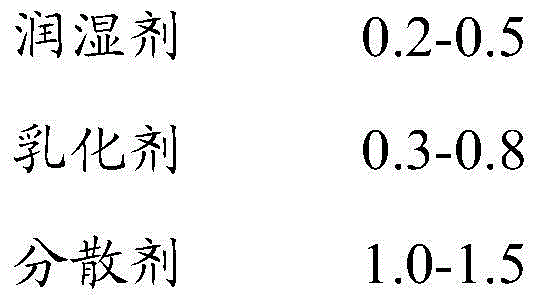

[0060] A kind of water-based self-cleaning wood topcoat of the present embodiment comprises the raw material of following weight portion:

[0061]

[0062]

[0063] The preparation method is as follows:

[0064] (1) adding water-based silica sol and functional powder to the reactor in sequence for blending to obtain self-cleaning water-based silica sol;

[0065] (2) Water-dispersed polyurethane resin or water-dispersed alkyd resin, functional additives, self-cleaning water-based silica sol and water obtained in step (1) are added to the reactor and blended successively, and are dispersed at high speed and sand-milled for 200 mesh filter screen to obtain the self-cleaning water-based wood finish paint.

[0066]The average particle size of the aqueous silica sol used in this example is 26 nm. The average particle size of the nanometer talcum powder, nanometer kaolin and nanometer talcum powder used is 3 μm. The prepared water-based self-cleaning wood topcoat has good co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com