High-performance extreme pressure antiwear emulsified cutting oil and preparation method thereof

An extreme pressure anti-wear, cutting oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor transportation and storage, and achieve good anti-wear effect, no irritating odor, and enhanced lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

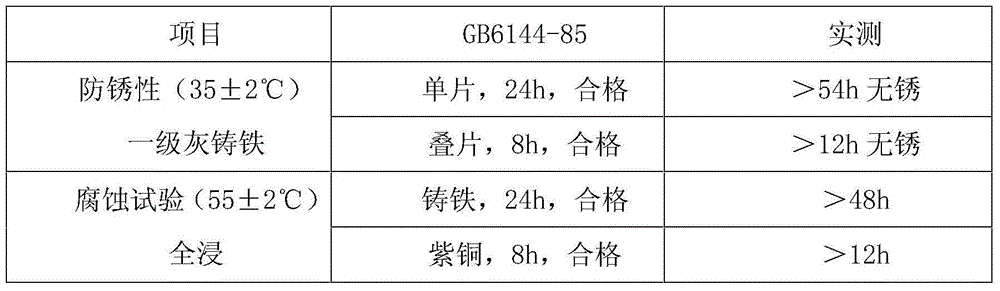

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below through specific examples.

[0013] A high-performance extreme pressure anti-wear emulsified cutting oil, made of the following raw materials in parts by weight (kg): liquid paraffin 19, light oil 30, furfural extraction oil 13, Span-808, N, N'-diethylene Salicylpropylenediamine 2, sebacic acid 2, dodecene 3, sodium borate 5, dibutyl phosphite 2, copper powder 2.5, sodium petroleum sulfonate 2, butyl carbitol 2, modified waste engine oil 9;

[0014] The modified waste engine oil is prepared from the following raw materials in parts by weight (kg): waste engine oil 45, waste diesel oil 10, activated clay 2, NP-51, cerous nitrate 1, lauryl polyoxyethylene ether 2, Colloidal silicon dioxide 2.5, urotropine 1, E-44 epoxy resin 3, methyl methacrylate 2, dibutyl phthalate 1, molybdenum disulfide 2; After mixing diesel oil, heat up to 120°C-140°C, add activated clay at constant temperature, stir for 30-40 minutes, let s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com