Method for promoting residual sludge to carry out anaerobic fermentation to produce acid

A technology for anaerobic fermentation of sludge and excess sludge, applied in fermentation and other directions, can solve the problems of high equipment requirements and large energy consumption of ultrasonic pretreatment methods, so as to save operating costs, shorten sludge fermentation time, and promote dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

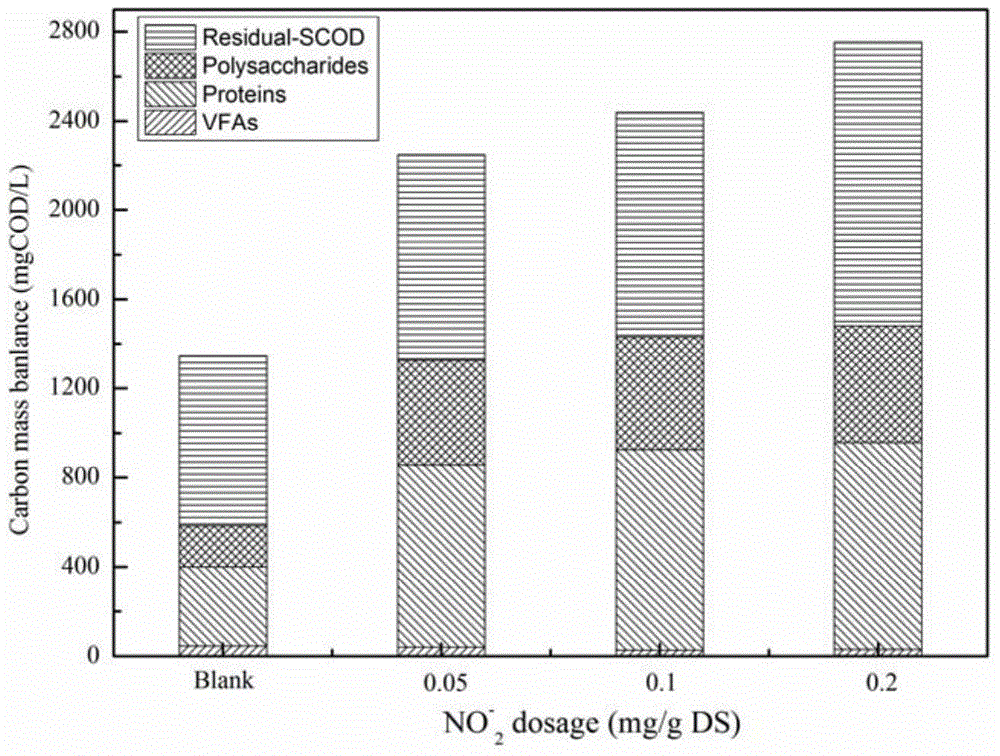

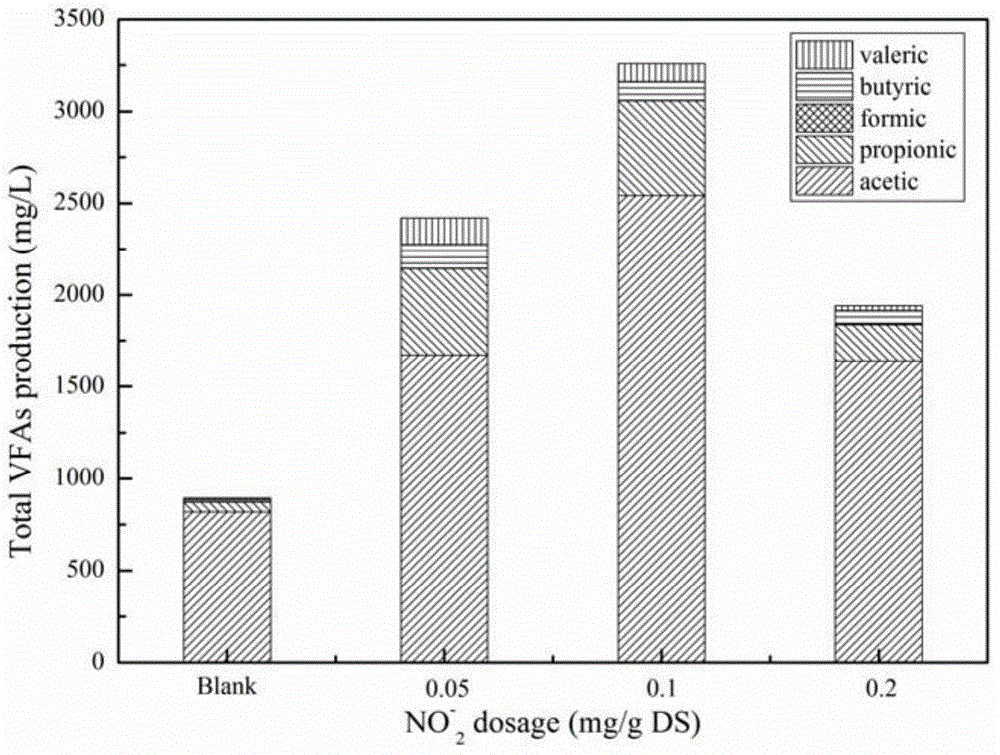

[0027] Take 250mL of excess sludge (water content 97%, pH=6.87) and put it into an anaerobic reactor for fermentation to produce acid. The dosage of nitrite in the pretreatment guarantees NO 2 - =0.05g / g DS, pretreatment time is 24h, pH is 5.0. Nitrogen and deoxygenation were performed for 10 minutes during the alkaline digestion process, the pH value was adjusted to 9.0, the reaction temperature was 30±1°C, the residence time in the reactor was 3 days, and the short-chain fatty acid produced was 873 mg per liter.

Embodiment 2

[0029] Take 250mL of excess sludge (water content 97%, pH=6.87) and put it into an anaerobic reactor for fermentation to produce acid. The dosage of nitrite in the pretreatment guarantees NO 2 - =0.1g / g DS, pretreatment time is 24h, pH is 5.0. Nitrogen and deoxygenation were carried out for 10 minutes during the alkaline digestion process, the pH value was adjusted to 9.0, the reaction temperature was 30±1°C, the residence time in the reactor was 3 days, and the short-chain fatty acid produced was 1045 mg per liter.

Embodiment 3

[0031] Take 250mL of excess sludge (water content 97%, pH=6.87) and put it into an anaerobic reactor for fermentation to produce acid. The dosage of nitrite in the pretreatment guarantees NO 2 - =0.2g / g DS, pretreatment time is 24h, pH is 5.0. Nitrogen and deoxygenation were carried out for 10 minutes during the alkaline digestion process, the pH value was adjusted to 9.0, the reaction temperature was 30±1°C, the residence time in the reactor was 3 days, and the short-chain fatty acid produced was 781 mg per liter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com