High temperature sealing coating and making method thereof

A sealing coating and high-temperature technology, applied in the field of high-temperature sealing coating and its preparation, can solve the problems of frequent repairs, wear of engine blades, short working life, etc., to improve wearability and service life, and improve bonding strength , the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

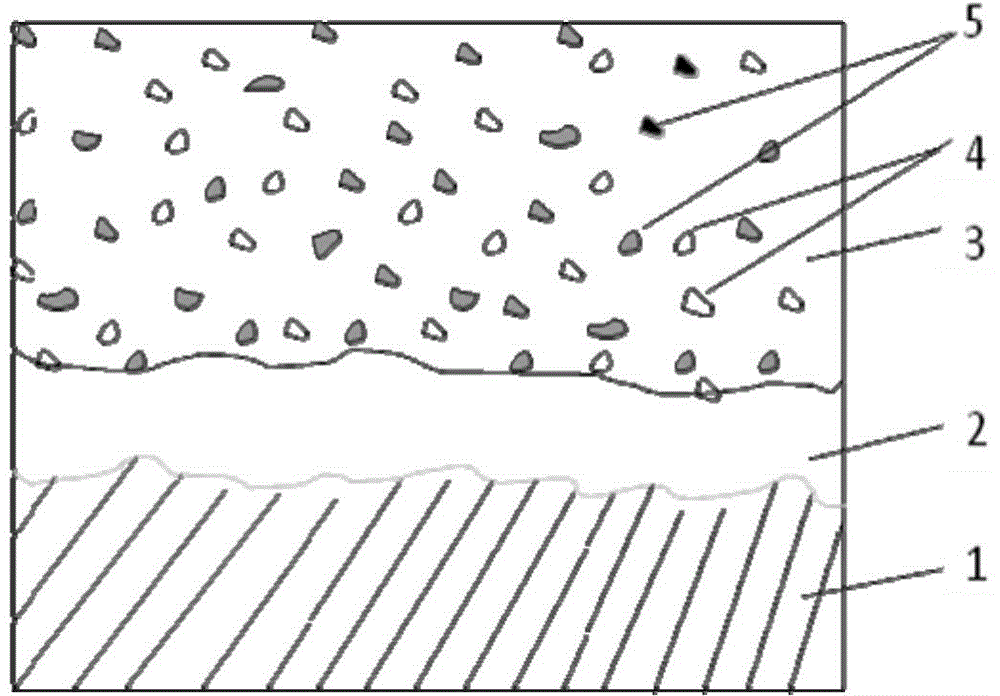

[0043] The present embodiment provides a kind of high-temperature sealing coating, and it comprises sealing coating bottom layer (cold gas power sprays NiCoCrWMoSiB high-temperature solder alloy powder and makes) and sealing coating surface layer (polyphenylene ester of plasma spraying 10wt%) , 5wt% BaF 2 / CaF 2 and the rest of the NiCrAlYSi alloy powder mixed powder made).

[0044] This embodiment also provides a method for preparing the above-mentioned high-temperature sealing coating, which specifically includes the following steps:

[0045] Clean the superalloy substrate 1 with No. 120 aviation gasoline, and blast the superalloy substrate 1 with clean and dry brown corundum sand;

[0046] Spray NiCoCrWMoSiB high-temperature brazing alloy powder on the sandblasted superalloy substrate 1 by means of cold air power spraying, and form the bottom layer 2 of the high-temperature sealing coating on the substrate. The thickness of the bottom layer 2 of the high-temperature seali...

Embodiment 2

[0051] The present embodiment provides a kind of high temperature sealing coating, and it comprises sealing coating bottom layer (cold gas dynamic spraying NiCrCoSiB high temperature brazing material alloy powder is made) and sealing coating surface layer (polyphenylene ester of plasma spraying 7wt%) , 5wt% BaF 2 / CaF 2 and the rest of the NiCoCrAlTaY alloy powder mixed powder made).

[0052] This embodiment also provides a method for preparing the above-mentioned high-temperature sealing coating, which specifically includes the following steps:

[0053] Clean the superalloy substrate with No. 120 aviation gasoline, and blast the superalloy substrate with clean and dry brown corundum sand;

[0054] Spray NiCrCoSiB high-temperature brazing alloy powder on the sandblasted superalloy substrate by means of cold air power spraying, and form a bottom layer of high-temperature sealing coating on the substrate. The thickness of the bottom layer of high-temperature sealing coating is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com