Electrochromic device and preparation method and application thereof

An electrochromic device and electrochromic layer technology, which can be used in instruments, nonlinear optics, optics, etc., can solve the problems of high production cost and difficulty in large-scale production, and achieve low cost and relatively high production cost. High, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] As a specific embodiment of the preparation method of the electrochromic device provided by the present invention, it includes the following steps:

[0035] Step S100, depositing a first conductive layer on the surface of the first substrate by using a coating process.

[0036] Step S200, depositing a first electrochromic layer on the surface of the first conductive layer with a mask.

[0037] In step S300, an electrolyte layer and a second conductive layer are sequentially deposited on the surface of the first electrochromic layer by using a coating process. That is, after the electrolyte layer is deposited on the surface of the first electrochromic layer, the second conductive layer is deposited on the surface of the electrolyte layer. The preparation of the single-layer electrochromic device can be completed. Alternatively, after depositing the second conductive layer on the surface of the second substrate, the second conductive layer and the first electrochromic l...

Embodiment 1

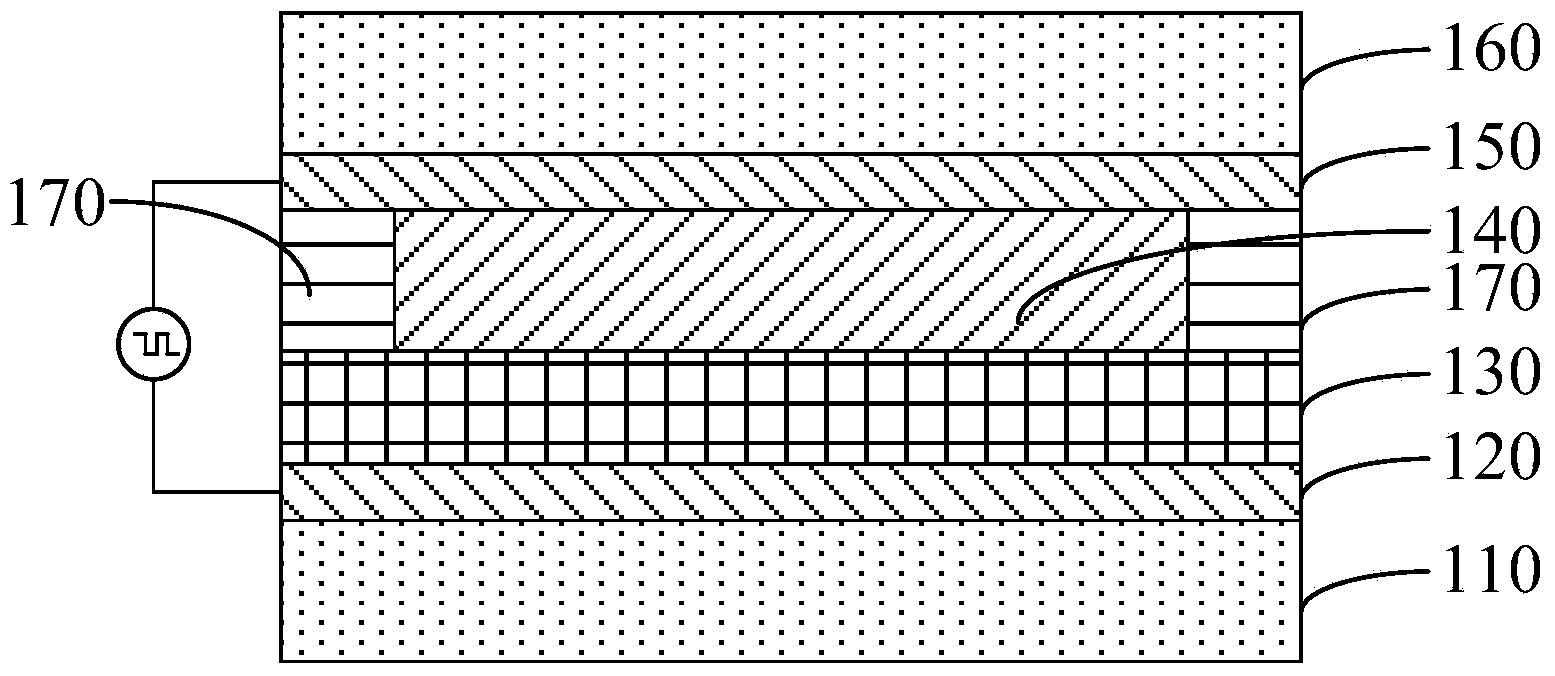

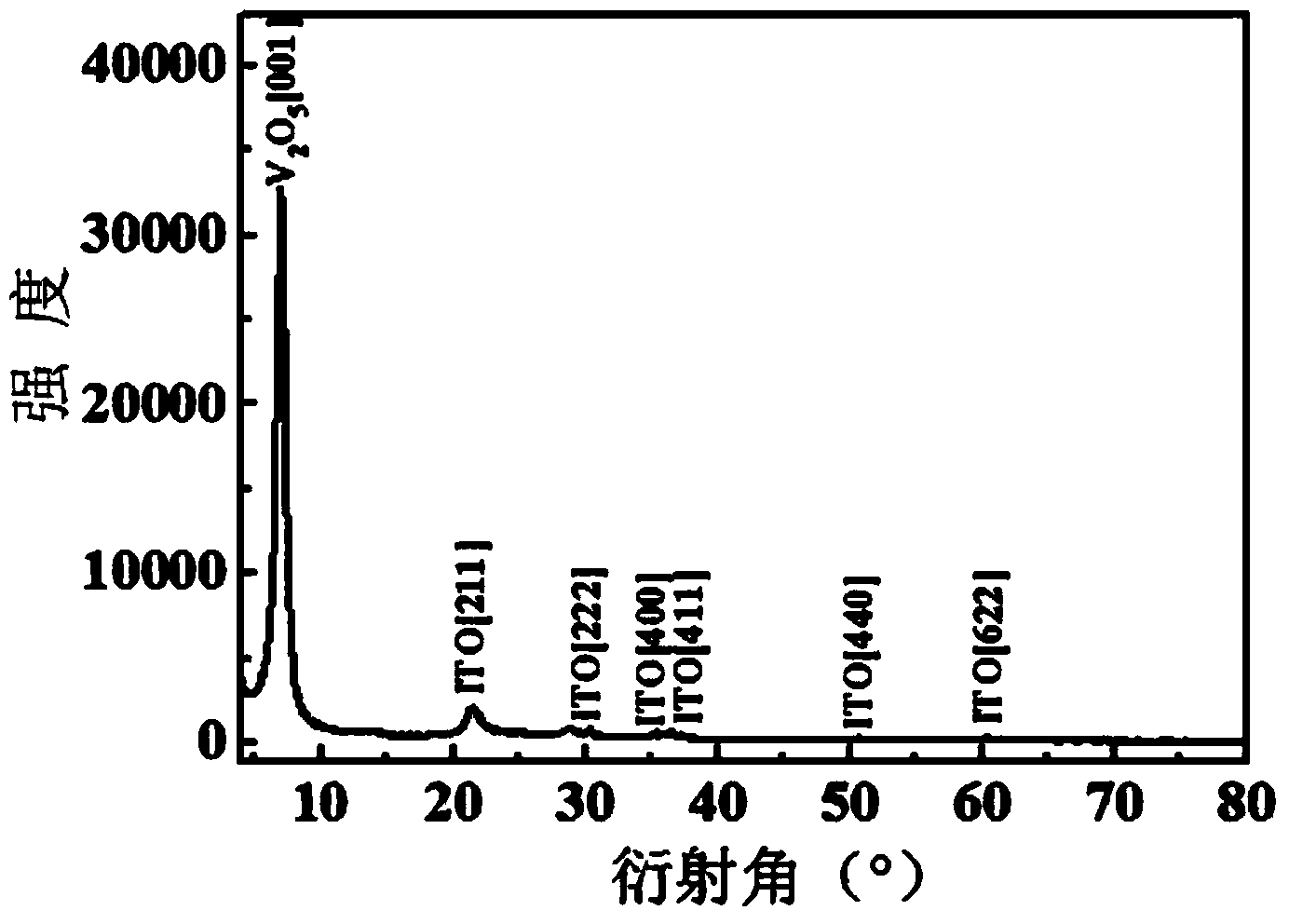

[0066] see figure 1 In the single-layer multi-color electrochromic device provided in Embodiment 1, the first substrate 110 is an ordinary transparent glass sheet. The first conductive layer 120 is an indium tin oxide (ITO) film, which is used to communicate with an external power source and serves as a cathode electrode. The first electrochromic layer 130 is a molybdenum-doped vanadium pentoxide film. The electrolyte layer 140 is a polymer lithium salt solid electrolyte membrane. The second substrate 160 is an ordinary transparent glass sheet. The second conductive layer 150 is an ITO film, which is used to communicate with an external power source and serves as an anode electrode. Use epoxy resin 170 to laminate and seal the two coated transparent glass sheets.

[0067] The preparation method of the above-mentioned single-layer electrochromic device comprises the following steps:

[0068] First, the area cleaned by ultrasonic cleaning with acetone and absolute ethanol s...

Embodiment 2

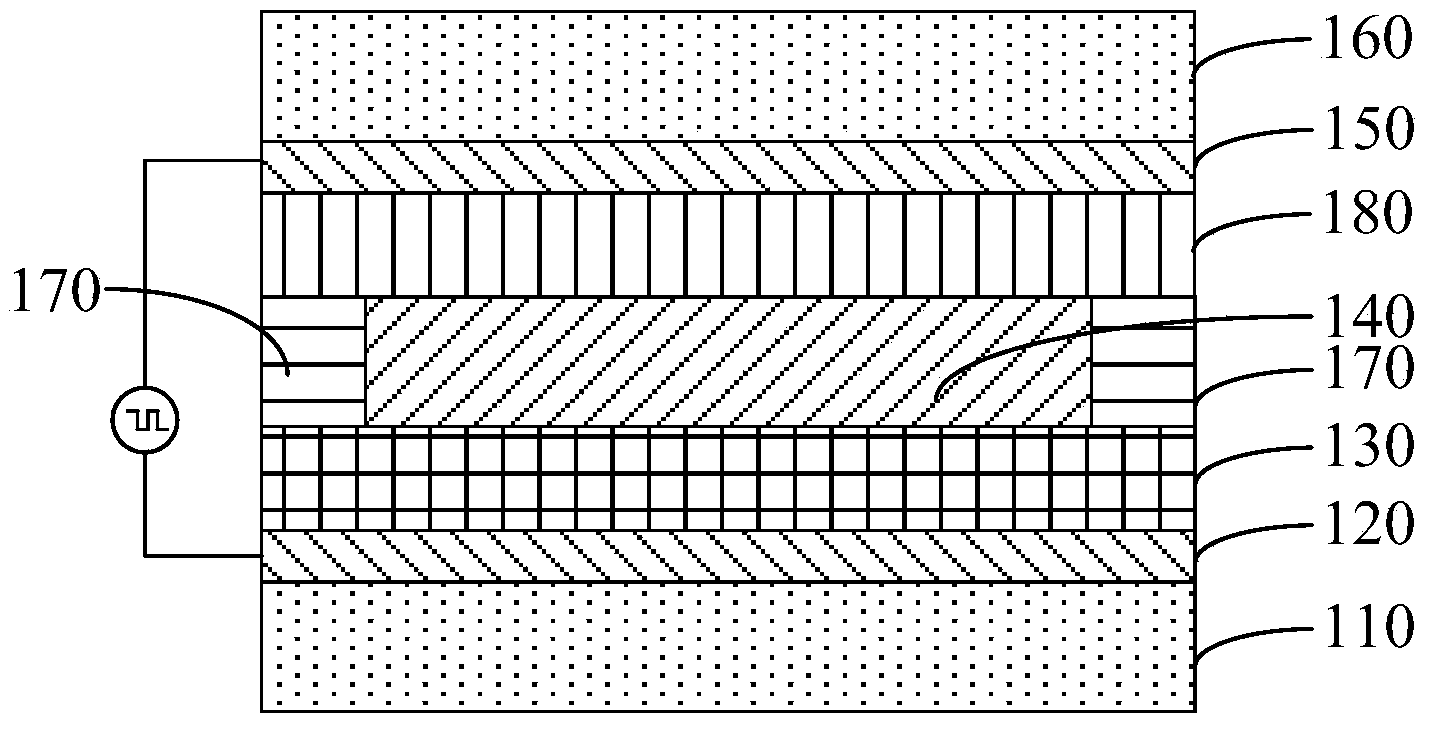

[0078] see figure 2 , is a specific embodiment of a double-layer electrochromic device, and the first substrate 110 is an ordinary transparent glass sheet. The first conductive layer 120 is an indium tin oxide (ITO) film, which is used to communicate with an external power source and serves as a cathode electrode. The first electrochromic layer 130 is a molybdenum-doped vanadium pentoxide film. The electrolyte layer 140 is a polymer lithium salt solid electrolyte membrane. The second substrate 160 is an ordinary transparent glass sheet. The second conductive layer 150 is an indium tin oxide (ITO) film, which is used to communicate with an external power source and serves as an anode electrode. The second electrochromic layer 180 is tungsten oxide (WO 3 ) or nickel oxide (NiO) films. Use epoxy resin 170 to laminate and seal the two coated transparent glass sheets.

[0079] The manufacturing method of the above-mentioned double-layer electrochromic device comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com