Modified coke for treating aged landfill leachate, preparation method of modified coke and treatment method of aged landfill leachate

A technology of landfill leachate and activated coke, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of transferring pollutants back to the environment, increasing the process and treatment costs, and expanding the pores. Compared with the adsorption specific surface, the effect of solving the difficult treatment and increasing the adsorption capacity and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the preparation of modified coke product

[0033] Take industrial coke and grind it into a fine particle powder and pass it through a 200-mesh sieve. Put 1kg of the sieved powder into a 2L 5% sodium hydroxide dilute lye heating kettle and boil for 15 minutes, cool and filter.

[0034] Put the coke powder after alkali cooking into the enamel reaction kettle with 3-10% dilute nitric acid solution with a concentration of 3-8% copper nitrate dissolved in advance, soak at room temperature for 2 hours, filter, separate, and wash with water to pH If it is neutral, put it in a drying oven at 105°C and dry it for later use.

[0035] Take 1.7L of butyl phthalate (industrial pure grade) and add it to a reaction kettle filled with 8L ethanol (industrial pure grade) in advance, stir at room temperature until dissolved, then add 30g of iron nitrate, adjust pH=2-3 with dilute nitric acid, Stir at low temperature for 30 minutes, then add 1kg of activated coke to the reac...

Embodiment 2

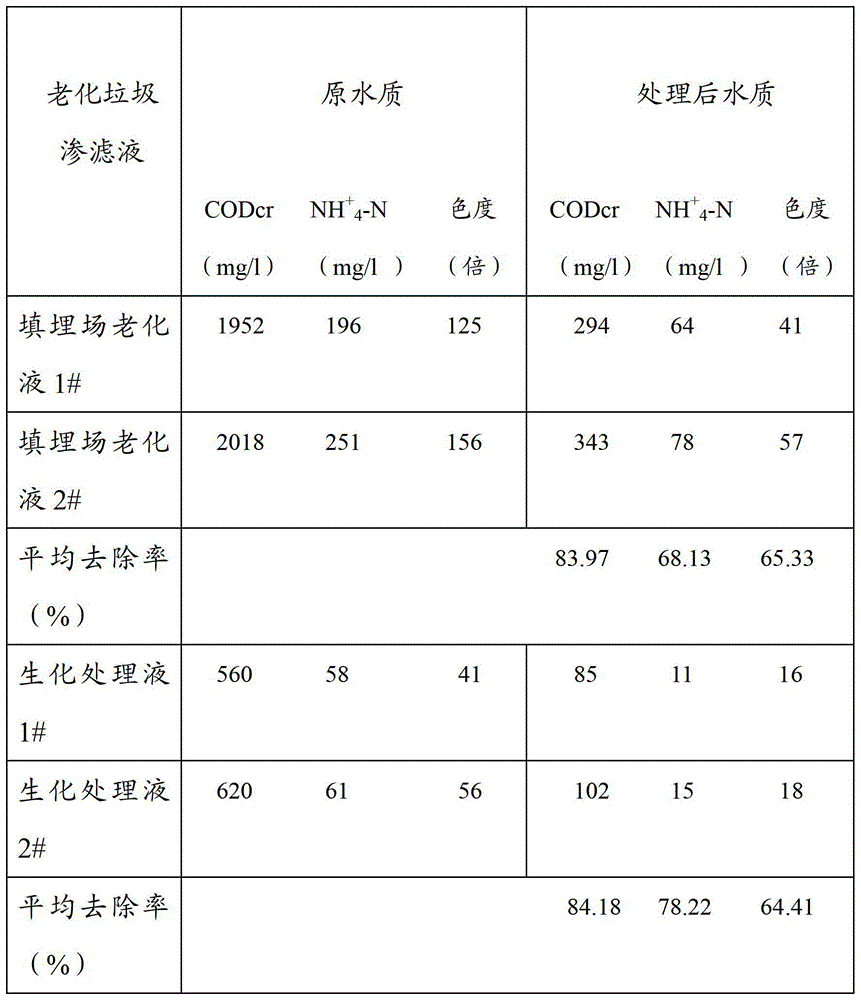

[0036] Implementation example 2, the treatment test of different aged landfill leachates

[0037] Put 1 kg of the modified coke product obtained through the above steps into a filter column with a diameter of 20 cm and fill it up.

[0038] Adjust the pH of 20L landfill leachate in the head tank to about 8, then let it flow in from the upper conduit, slowly pass through the coke reaction adsorption column, and then flow out from the lower conduit. The flow rate is controlled by the flow valve, and the flow rate is 0.8m / h. The leachate is taken from the waste landfill and the outlet of the biochemical treatment process of the landfill leachate treatment plant. The test results are shown in Table 1.

[0039] The results show that the modified coke has obvious effects on water quality indicators such as CODcr, NH+4-N and chromaticity of aged landfill leachate degraded by different biological methods. The waste coke after saturated adsorption can still be recovered as fuel withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com