Mechanical apparatus for preparing poly aluminium chloride

A technology of polyaluminum chloride and mechanical devices, applied in the direction of aluminum chloride, aluminum halide, etc., can solve the problems of high production costs, achieve the effects of good operating conditions, low water purification costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

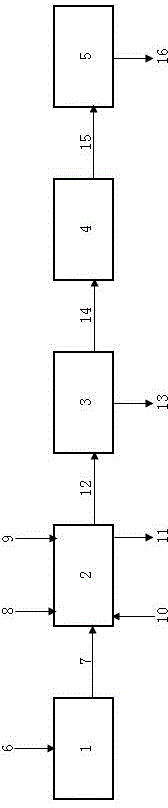

[0011] Further illustrate below in conjunction with accompanying drawing and use this mechanical device to prepare the concrete content of the best embodiment of polyaluminum chloride:

[0012] 1. Send the concentrated ore kaolin accounting for 16% of the total amount into the roasting furnace 1 through the concentrated ore kaolin inlet 6 arranged on the roasting furnace 1, and roast at a temperature of 350-400°C for 1.5-2 hours, then stop roasting, and cool down to room temperature for later use.

[0013] 2. The industrial-grade hydrochloric acid that accounts for 37% of the total amount is sent into the stirring tank 2 through the industrial-grade hydrochloric acid inlet 8 arranged on the stirring tank 2, and 13% of the total amount is added through the water inlet 9 arranged on the stirring tank 2 Water, after stirring evenly, start to heat up to 55-65°C, send the roasted concentrate kaolin in the roasting furnace 1 into the stirring tank 2 through the first conveyor 7 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com