Layer-like germanium quantum dot material and preparation method thereof

A quantum dot material, layered technology, applied in metal material coating process, nanotechnology for materials and surface science, coating and other directions, can solve the problems of uneven size of Ge quantum dots, difficult composition control, etc. The effect of controllable composition and structure, uniform size, and adjustable band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

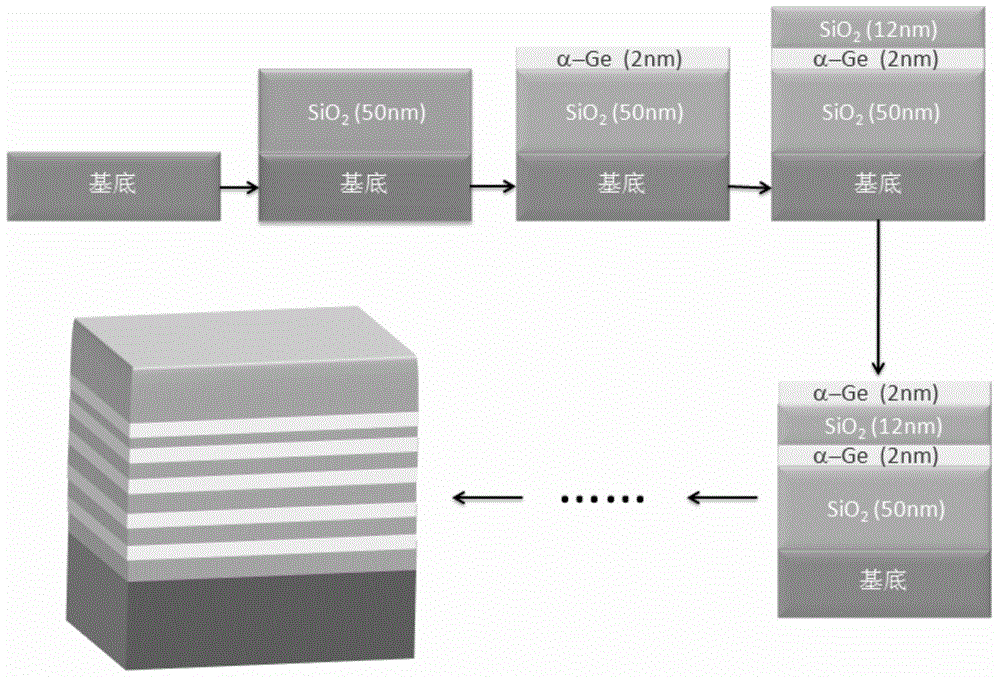

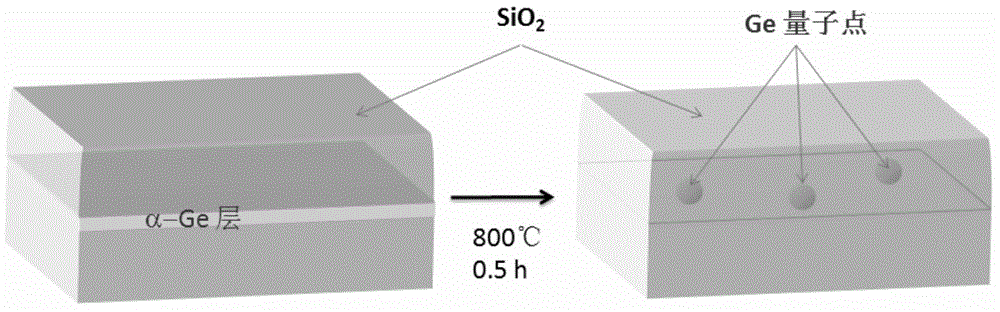

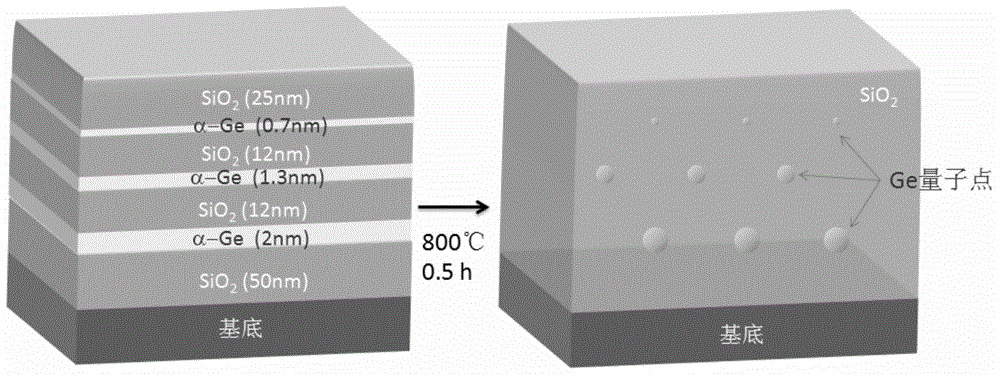

[0022] The invention provides a method for preparing a layered germanium quantum dot material, the method comprising: alternately depositing SiO on a substrate 2 layer and Ge layer, and annealed.

[0023] In the present invention, conventional experimental materials in this field can be used as the substrate, such as Si sheet, quartz glass sheet and the like. The size of the substrate can be 1-10 inches, for example, can be 4 inches. Preferably, the substrate can also be cleaned before preparing the germanium quantum dot material of the present invention, and the cleaning method is well known to those skilled in the art.

[0024] In the present invention, the deposition method can achieve alternate deposition of SiO 2 Layers and individual layers are fine. In order to make the performance of the product more superior, it is preferred that the deposition method includes magnetron sputtering, and the magnetron sputtering method includes: under the condition of magnetron sputt...

Embodiment 1

[0034] This example is used to illustrate the preparation of uniform layered Ge quantum dot materials by the method of the present invention.

[0035] The material of the substrate is quartz glass (thickness 1mm), and the substrate is soaked in acetone and deionized water for 10 minutes, respectively, and ultrasonically cleaned for 10 minutes, wherein the ultrasonic frequency is 20kHz, and the ultrasonic power is 800W.

[0036] Load Ge target and SiO in the magnetron sputtering apparatus 2 target. After starting the magnetron sputtering apparatus, vacuumize to about 2×10 -5 Pa (the same below), the working gas flow is argon 30sccm (the same below), SiO 2 The target power is set to 200W (the same below), SiO 2 The target deposition rate is 2.5nm / min, the Ge target power is set to 80W (the same below), the Ge target deposition rate is 2nm / min, and the deposition pressure is 0.21Pa (the same below).

[0037] Put the cleaned substrate into the magnetron sputtering apparatus. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com