Preparation method and application of high-performance coconut shell adjuvant

A coconut shell additive and high-performance technology, applied in the field of textile production, can solve the problems of increased heaviness, static electricity accumulation, friction increase, etc., to achieve strong ability to absorb ultraviolet rays, improve comprehensive performance, and improve flame retardant efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

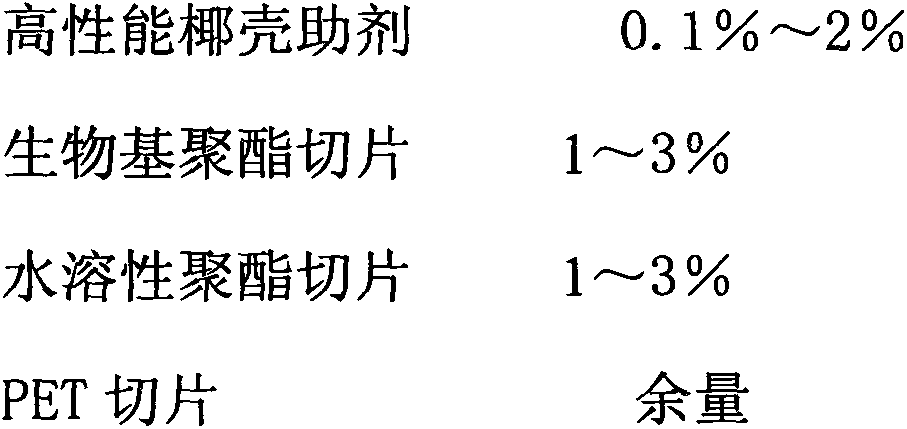

Method used

Image

Examples

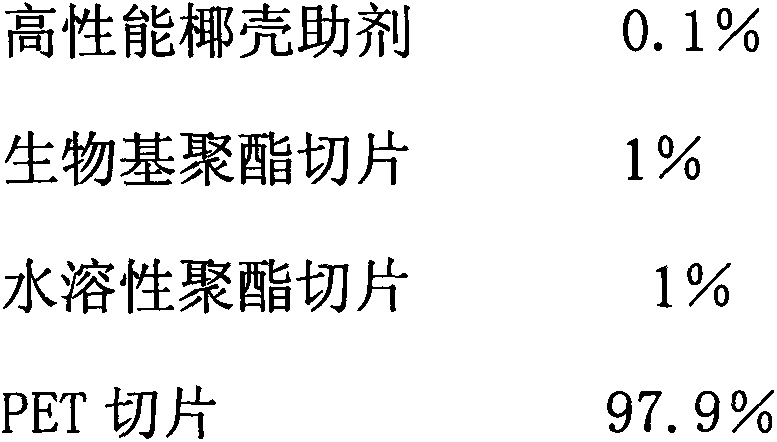

Embodiment 1

[0060] A kind of preparation method of high-performance coconut shell additive, its concrete steps are:

[0061] (1) Raw material pretreatment:

[0062] Coconut shells were dried at 80°C for 4 hours to obtain treated coconut shells;

[0063] (2) Carbonization treatment:

[0064] Carry out carbonization to obtain modified coconut shell powder with the processed coconut shell that step (1) obtains;

[0065] The carbonization process is to use a quartz tube furnace to carry out the segmental carbonization of coconut shells: the heating rate is raised to 200 ° C at a rate of 10 ° C / min, and the coconut shells are carbonized at 200 ° C for 80 minutes, and then the heating rate is 15 ° C / min Raise to 400°C, then carbonize at 400°C for 80 minutes, and finally raise the temperature to 700°C at a rate of 20°C / min, and carbonize at this temperature for 2 to 3 hours; after carbonization, grind the obtained product in a high-energy ball mill until In fine powder form, the modified ...

Embodiment 2

[0076] A kind of preparation method of high-performance coconut shell additive, its concrete steps are:

[0077] (1) Raw material pretreatment:

[0078] Coconut shells were dried at 80°C for 4 hours to obtain treated coconut shells;

[0079] (2) Carbonization treatment:

[0080] Carry out carbonization to obtain modified coconut shell powder with the processed coconut shell that step (1) obtains;

[0081] Described carbonization process is with embodiment 1.

[0082] (3) Aging modification:

[0083] Carrying out aging modification treatment to step (2) modified coconut shell powder, obtains composite coconut shell powder;

[0084] The modified coconut shell powder obtained in step (2) is dissolved in a strong acid solution, and the obtained modified coconut shell powder solution is added with nanomaterials and an aging agent, then stirred and ultrasonically dispersed, and then centrifuged to obtain a solid material. The solid material is dried at 40-60°C for 2-6 hours to ...

Embodiment 3

[0092] A kind of preparation method of high-performance coconut shell additive, its concrete steps are:

[0093] (1) Raw material pretreatment:

[0094] Coconut shells were dried at 80°C for 4 hours to obtain treated coconut shells;

[0095] (2) Carbonization treatment:

[0096] Carry out carbonization to obtain modified coconut shell powder with the processed coconut shell that step (1) obtains;

[0097] Described carbonization process is with embodiment 1.

[0098] (3) Aging modification:

[0099] Carrying out aging modification treatment to step (2) modified coconut shell powder, obtains composite coconut shell powder;

[0100] The modified coconut shell powder obtained in step (2) is dissolved in a strong acid solution, and the obtained modified coconut shell powder solution is added with nanomaterials and an aging agent, then stirred and ultrasonically dispersed, and then centrifuged to obtain a solid material. The solid material is dried at 40-60°C for 2-6 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com