Natural rubber, rubber composition comprising natural rubber and method for producing same, and tire

A technology of natural rubber, production method, applied in the direction of special tires, tire parts, transportation and packaging, etc., to achieve the effect of suppressing the deterioration of processability, excellent physical properties, excellent fracture resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

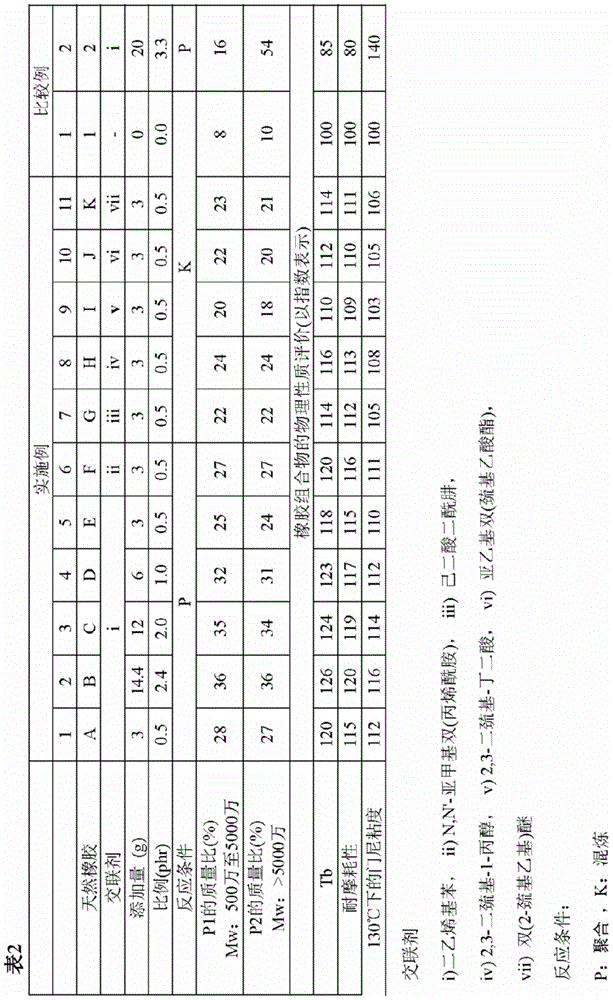

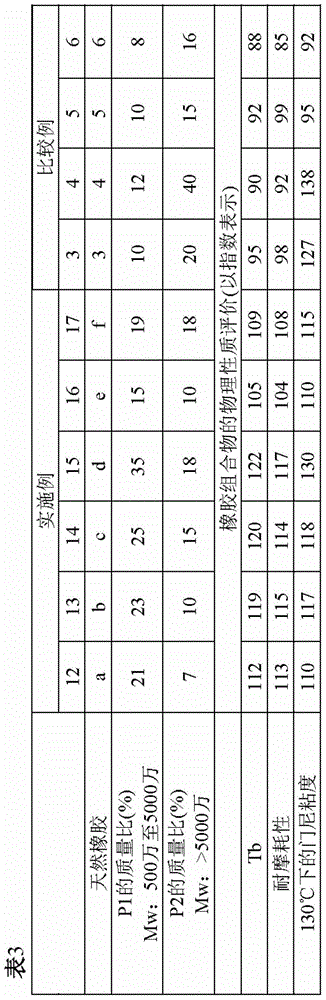

Examples

Embodiment 1

[0104] 2000 g of field latex containing 600 g of solid matter was put into a reaction vessel made of stainless steel equipped with a stirrer and a temperature control jacket, and was previously added by dissolving 100 mg of emulsifier Emulgen 1108 manufactured by Kao Corporation in 20 ml of water to An emulsion prepared from 3.0 g of divinylbenzene was added to the field latex along with 280 ml of water. The above mixture was stirred at room temperature for 30 minutes while removing oxygen by bubbling nitrogen.

[0105] Next, 1.0 g of t-butyl hydroperoxide t-BHPO as a polymerization initiator and 1.0 g of tetraethylenepentamine TEPA as an emulsion stabilizer were added thereto to react them at 40° C. for 1 hour, thereby obtaining a polymerized natural latex.

[0106] Formic acid was added to the natural latex thus obtained to control its pH to 4.7, thereby coagulating the natural latex. The solid matter thus obtained was treated 5 times with a spatula, then passed through a ...

Embodiment 2

[0109] Production was carried out under the same conditions except that 14.4 g of divinylbenzene was added instead of 3.0 g of divinylbenzene in Example 1, whereby natural rubber B was obtained. According to the compositions shown in Table 1 above, rubber compositions were obtained.

Embodiment 3

[0111] Production was performed under the same conditions except that 12.0 g of divinylbenzene was added instead of 3.0 g of divinylbenzene in Example 1, whereby natural rubber C was obtained. According to the compositions shown in Table 1 above, rubber compositions were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com