Metal support with micro-nano structure on surface

A metal stent, micro-nano structure technology, applied in the direction of human tubular structure devices, stents, blood vessels, etc., can solve the problems of uneven drug release, endothelial growth delay, aneurysm and other problems, and achieve the effect of overcoming restenosis and facilitating clinging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

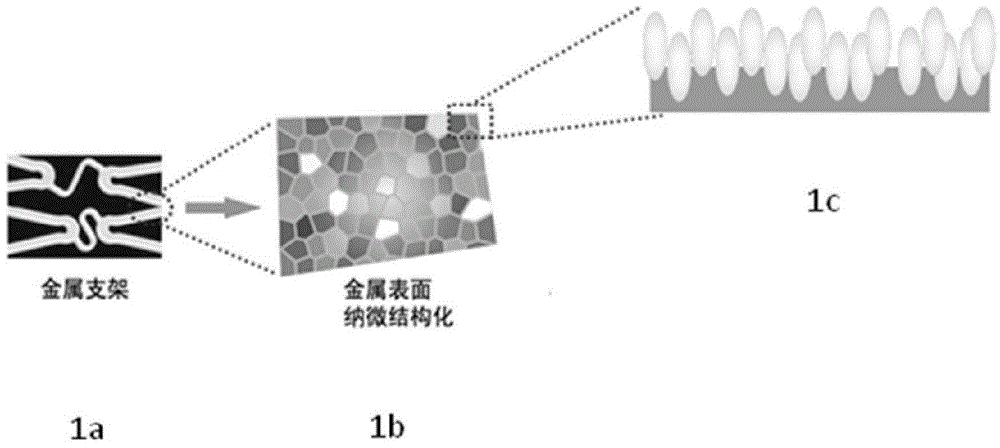

[0019] Such as figure 1 a~ figure 1 As shown in c, a metal stent with a micro-nano structure on the surface, the stent structure is the same as the existing bare metal stent, characterized in that the surface of the metal stent has a micro-nano structure.

[0020] see figure 1 a, is a picture of the metal scaffold structure with micro-nano structure on the surface of the present invention. The structure and material of the metal stent of the present invention are the same as the metal stent before the drug-eluting stent (DES) of the prior art is coated with a coating, the difference is that the metal stent with micro-nano structure on the surface of the present invention needs Micro-nano structures are processed on the surface of the metal support in the prior art.

[0021] see figure 1 b, is a micrograph of a metal stent with a micro-nano structure on the surface of the present invention. Under a certain magnification, it can be seen that the surface of the metal stent ha...

Embodiment 2

[0026] The surface of the metal stent described in this embodiment has a micro-nano structure. The micro-nano structure processed on the surface of the metal stent in the prior art is the same as that in Example 1. The difference is that the surface of the metal stent is coated with Covered with biodegradable polymer material coating. It should be pointed out that although the surface of the metal stent is coated with a biodegradable polymer material coating, there is no need to load drugs, genes, antibodies or block polymers, etc. Obviously, this is different from the coating of the surface of the metal stent in the prior art. There are obvious differences between coating with biodegradable polymer materials and loading drugs, genes, antibodies or block polymers.

[0027] The biodegradable polymer material selected in this example should have such properties: it is very easy to combine with the metal scaffold with micro-nano structure on the surface, and it is easy to quickly...

Embodiment 3

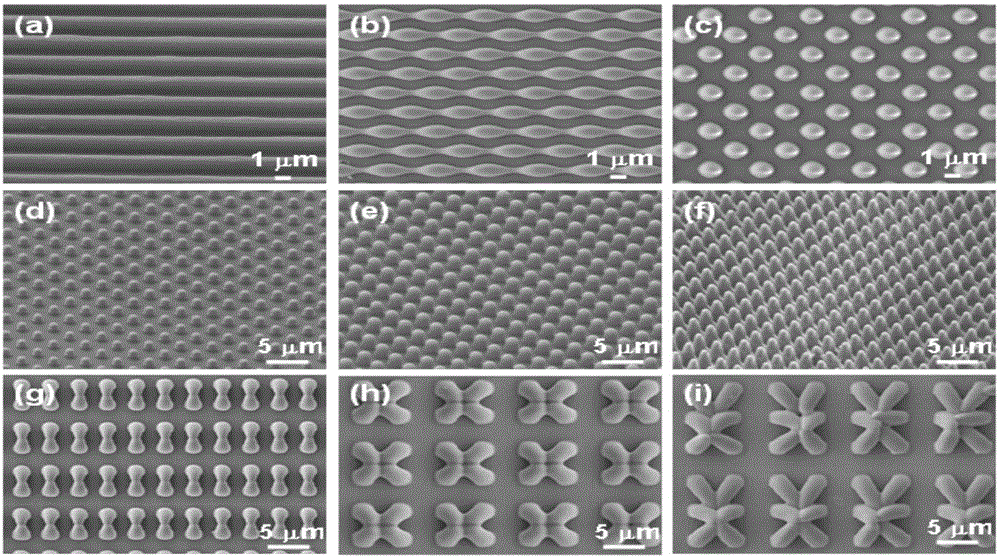

[0031] The current clinical research on coronary stents is mainly devoted to surface modification of stents in order to reduce the occurrence of thrombus and intimal hyperplasia. There are two main ways of modification. The first way is to change the physical and chemical properties of the scaffold surface through physical and chemical methods, and the second way is to load drugs, genes, cells, etc. through suitable carriers. Examples 1 and 2 adopted the first approach: using multi-beam laser processing to prepare micro-nano structures on the surface of the metal stent, which expanded the adsorption area and created conditions for rapid adsorption of endothelial cells and rapid endothelialization. When using the second approach, the carrier is generally a degradable polymer material, but some suitable carriers cannot be used because they cannot be firmly adsorbed to the metal stent. After the micro-nano structures are prepared on the surface of the metal stent by using multi-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com