PVDF membrane with antifouling property and preparation method of PVDF membrane with antifouling property

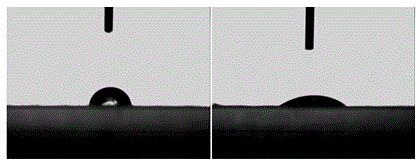

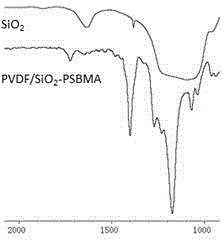

A technology of anti-fouling performance and membrane solvent, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem that zwitterionic polymers cannot be dissolved, and achieve the characteristics of inhibiting easy agglomeration, obvious anti-fouling performance, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of PVDF Flat Membrane with Antifouling Function

[0054] 1. Preparation of modified titania nanoparticles

[0055] 1) Disperse 1 g of titanium dioxide nanoparticles into 20 ml of Tris-HCl buffer solution with a pH of 8.5; add 0.1 g of dopamine, react at 30 °C for 2 h, filter after the reaction, separate the nanoparticles, and dry them in vacuum until use;

[0056] 2) Disperse 1 g of nanoparticles obtained in step 1) into 30 ml of tetrahydrofuran, add 1 ml of triethylamine; then add 10 ml of tetrahydrofuran solution containing 3 ml of bromopropionyl bromide dropwise into the nanoparticle dispersion , reacted at 0 °C for 1 h; centrifuged, cleaned the nanoparticles with 100 ml 50 wt% ethanol aqueous solution, and dried in vacuum for later use;

[0057] 3) Disperse the nanoparticles obtained in step 2) into a flask containing 20 ml of tetrahydrofuran, and add CuBr, EBiB, PMDETA and DMAEMA at a molar ratio of 1:1:1:100, wherein the amount of CuBr is 0.1 mmol; ...

Embodiment 2

[0070] Preparation of PVDF Flat Membrane with Antifouling Function

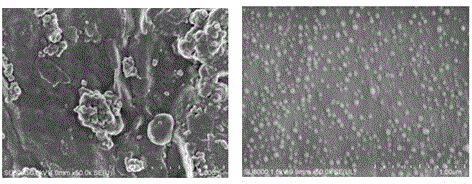

[0071] 1. Preparation of Modified Silica Nanoparticles

[0072] 1) Disperse 1 g of silica nanoparticles into 15 ml of Tris-HCl buffer solution with a pH of 8.5; add 0.5 g of dopamine, react at 40 °C for 10 h, filter after the reaction, separate the nanoparticles, and vacuum dry and ready to use;

[0073] 2) Disperse 1 g of nanoparticles obtained in step 1) into 30 ml of tetrahydrofuran, add 1 ml of triethylamine; then add 10 ml of tetrahydrofuran solution containing 3 ml of bromopropionyl bromide dropwise into the nanoparticle dispersion , reacted at 0 °C for 5 h; centrifuged, cleaned the nanoparticles with 200 ml 50 wt% ethanol aqueous solution, and dried in vacuum for later use;

[0074] 3) Disperse the nanoparticles obtained in step 2) into a flask containing 20 ml of tetrahydrofuran, and add CuBr, EBiB, PMDETA and DMAEMA at a molar ratio of 1:1:1:300, wherein the amount of CuBr is 0.1 mmol; Use nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com